Description

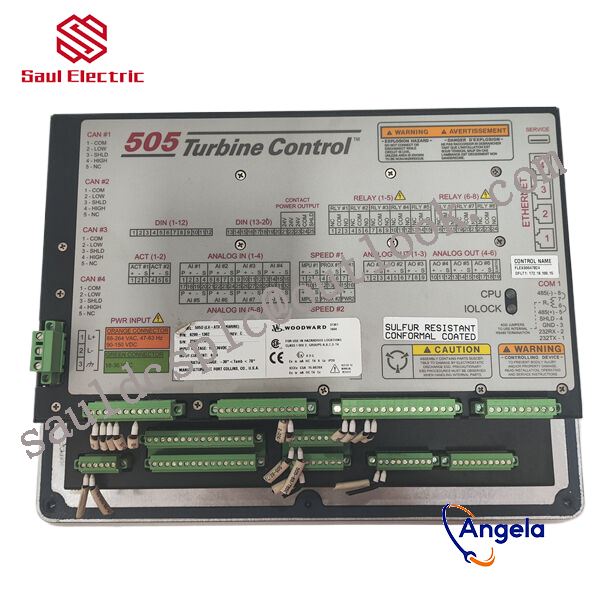

5463-140 Controller debugger generator WOODWARD

Non differential regulation is mainly used for constant speed control and is suitable for single machine operation or multiple prime movers working together in an isolated power grid. Differential regulation provides more control flexibility.

further enhancing its performance and application range.

rich additional functions, and high-precision output signals. Whether it is in the fields of generator sets, compressors, pump stations, or ships and locomotives, it can effectively ensure the stable operation of equipment within the set range.

power measurement level 1, editable screen, multi interface toolkit connection, etc. All details can be found in Woodward easyYgen manual 37582A

The rated operating temperature range of this model is -20 to 70 ° C; the rated temperature range of the LT model is -40 to 70 ° C, suitable for outdoor use.

5463-140 is equipped with a monitor (not available on the 3100 model) and is designed for front panel installation.

The built-in HMI has a color LCD and soft keys (now with dedicated buttons) for direct control of the 5463-140 device. Multi level password protection can prevent unauthorized changes.

The generator set has four operating modes and the option to configure a manual circuit breaker control device.

How to use 5463-140?

What is 5463-140 used for?

5463-140 Customs Code

Some people say that such robots will take away workers” jobs, but if you go to those factories, you will know that no young people can endure such work for a long time. An assembly company recruits a worker and needs to familiarize him with it for three to four months, but the worker will leave after working for five to six months. Therefore, it is difficult for these industries to find enough skilled workers to ensure product quality, which is very frustrating for entrepreneurs.Reporter: Recently, several major economies in the world have proposed their own long-term goals for the manufacturing industry. China has proposed “Made in China 2025”, Germany has proposed “Industry 4.0”, and the United States has also proposed “Industrial Internet”. As a technical expert, what do you think? What problems and challenges does the global manufacturing industry face?Claes Rytoft: Actually, it doesn’t matter what the name is. The most important phenomenon is that global manufacturing technology has undergone tremendous changes in three directions in the past few years. The first is that sensors are becoming cheaper and cheaper, the second is that communication speeds are getting faster and faster, and the third is that computing power is also growing exponentially and explosively. These three technologies are integrating with each other, giving rise to the upgrading of the manufacturing industry. It can improve production efficiency and reduce the scrap rate in large-scale production. So these basic things are not actually a new concept. New technologies make the entire manufacturing process more dynamic and flexible.In the era of smart manufacturing, ABB robots can help manufacturing companies effectively improve production efficiencyOn November 5, the 2018 China International Import Expo opened grandly at the Shanghai National Convention and Exhibition Center. ABB brought more than 30 leading products and solutions from 8 countries to the stage, comprehensively displaying ABB”s latest global technologies and R&D achievements in the fields of digital power grids, intelligent manufacturing, and smart transportation. It also signed cooperation agreements with many domestic companies and wrote A new chapter in expanding openness and comprehensive cooperation.In the intelligent and high-end equipment manufacturing exhibition area, ABB displayed a number of advanced technologies, such as the compact robot IRB 2600 with high precision, high speed and high load, which is suitable for material handling, arc welding and other processing applications, and can help manufacturing companies effectively improve production Efficiency; ABB Ability motor smart sensors with built-in multiple sensors and combined with cloud applications have successfully helped many domestic industrial customers achieve predictive maintenance, shorten downtime, extend motor life and reduce energy consumption.

5466-341 WOODWARD Speed Sensor Full Series

9905-003 Controller debugger generator WOODWARD

5464-018 WOODWARD generator set speed control board

9907-019 WOODWARD Speed Sensor Full Series

8230-841 Generator Parts Speed Controller 2301A Speed

5501-411 Controller debugger generator WOODWARD

5500-562 Generator Parts Speed Controller 2301A Speed

5463-089 WOODWARD 2301A Speed Control Controller

5462-750 Generator Parts Speed Controller 2301A Speed

8290-191 Generator Parts Speed Controller 2301A Speed

8237-1242 From Woodward, USA

5464-210 WOODWARD 2301A Speed Control Controller

8901-457 WOODWARD generator set speed control board

9907-028 Controller debugger generator WOODWARD

5441-695 Generator Parts Speed Controller 2301A Speed

8272-781 WOODWARD Speed Sensor Full Series

5441-629 WOODWARD 2301A Speed Control Controller

5464-661 Controller debugger generator WOODWARD

5462-756 Generator Parts Speed Controller 2301A Speed

5501-471 From Woodward, USA

8200-1300 WOODWARD generator set speed control board

5464-332 Generator Parts Speed Controller 2301A Speed

8516-042 Generator Parts Speed Controller 2301A Speed

9905-972 Generator Parts Speed Controller 2301A Speed

8272-781 WOODWARD 2301A Speed Control Controller

9907-490 From Woodward, USA

5463-120 WOODWARD 2301A Speed Control Controller

5462-981 Controller debugger generator WOODWARD

5463-729 From Woodward, USA

8273-1011 Generator Parts Speed Controller 2301A Speed

9907-029 From Woodward, USA

8406-116 Generator Parts Speed Controller 2301A Speed

5430-929 Generator Parts Speed Controller 2301A Speed

8580-069 WOODWARD Speed Sensor Full Series

5464-355 WOODWARD Speed Sensor Full Series

5462-482 WOODWARD generator set speed control board

5463-373 Generator Parts Speed Controller 2301A Speed

8230-840 WOODWARD 2301A Speed Control Controller