Description

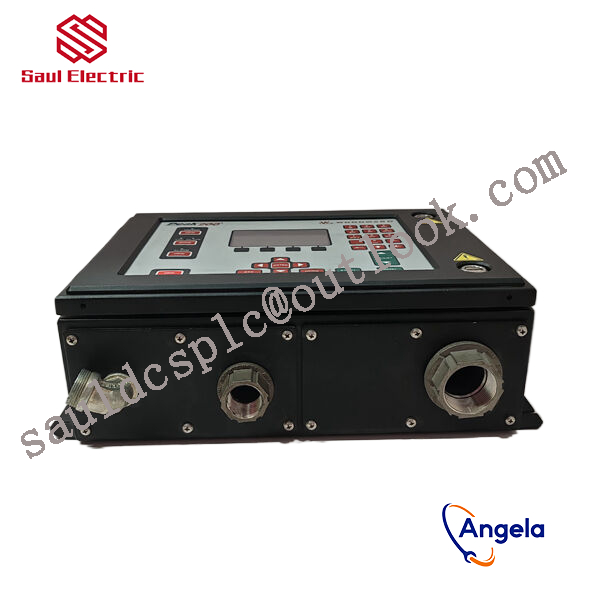

SPM-D11 8440-1706 Generator Parts Speed Controller 2301A Speed

Non differential regulation is mainly used for constant speed control and is suitable for single machine operation or multiple prime movers working together in an isolated power grid. Differential regulation provides more control flexibility.

further enhancing its performance and application range.

rich additional functions, and high-precision output signals. Whether it is in the fields of generator sets, compressors, pump stations, or ships and locomotives, it can effectively ensure the stable operation of equipment within the set range.

power measurement level 1, editable screen, multi interface toolkit connection, etc. All details can be found in Woodward easyYgen manual 37582A

The rated operating temperature range of this model is -20 to 70 ° C; the rated temperature range of the LT model is -40 to 70 ° C, suitable for outdoor use.

SPM-D11 8440-1706 is equipped with a monitor (not available on the 3100 model) and is designed for front panel installation.

The built-in HMI has a color LCD and soft keys (now with dedicated buttons) for direct control of the SPM-D11 8440-1706 device. Multi level password protection can prevent unauthorized changes.

The generator set has four operating modes and the option to configure a manual circuit breaker control device.

How to use SPM-D11 8440-1706?

What is SPM-D11 8440-1706 used for?

SPM-D11 8440-1706 Customs Code

The research and development, manufacturing and sales of high-end bearing steel are basically monopolized by the world”s bearing giants Timken of the United States and SKF of Sweden. In the past few years, they established bases in Yantai and Jinan, Shandong Province, purchased low-end materials from China, used their core technologies to make high-end bearings, and sold them to the Chinese market at ten times the price. Adding rare earths during the steelmaking process can make the original high-quality steel “stronger”. But how to add it is the core secret of the world”s bearing giants.High-pressure plunger pump 14 “High-pressure plunger pump, a thorn in the throat of China”s equipment manufacturing industry” (Science and Technology Daily, May 28)The hydraulic system is one of the key components in the equipment manufacturing industry. In all engineering fields and wherever there is mechanical equipment, the hydraulic system is inseparable. The high-pressure plunger pump is the core component of high-end hydraulic equipment and is called the “heart” of the hydraulic system. The scale of China”s hydraulic industry has become the second in the world in 2017, but the industry is large but not strong, especially high-pressure plunger pumps with rated pressures above 35MPa, more than 90% of which rely on imports. Compared with foreign brands, domestically produced hydraulic piston pumps have a large gap in technological advancement, working reliability, service life, variable mechanism control function and dynamic and static performance indicators. They are basically equivalent to those produced abroad in the early 1990s. level.Aeronautical Design Software 15″Aviation software is in embarrassment, and domestic aircraft design is under a “tightening curse”” (Science and Technology Daily, May 30)Since the 1980s, the world”s aviation industry has entered a new stage of digital design, and has now reached a level of dependence that makes it impossible to design without software. Designing an aircraft requires at least a dozen types of professional software, all of which are products from European and American countries. Domestic design units not only have to invest huge sums of money to purchase software, but also wear steel rings on their heads. Once the “spell” is recited, the entire aviation industry will be paralyzed. According to media reports, when the J-10 aircraft was designed, the entire metal components of the main load-bearing structure of the main landing gear were commissioned to be manufactured abroad. But after it was built, there was a problem with the retraction and retraction of the landing gear. There was a 5 mm error, so we had to re-order it. Just this small error affected the delay of the J-10″s first flight by eight or nine months. Without full digital software support, any slight error may become a nightmare for the manufacturing industry.

8200-203 WOODWARD 2301A Speed Control Controller

9907-076 Generator Parts Speed Controller 2301A Speed

8200-1302 WOODWARD generator set speed control board

8291-020 From Woodward, USA

9905-967 From Woodward, USA

5501-411 WOODWARD Speed Sensor Full Series

5441-637 Controller debugger generator WOODWARD

T87001 Generator Parts Speed Controller 2301A Speed

5466-341 Generator Parts Speed Controller 2301A Speed

5441-635 Generator Parts Speed Controller 2301A Speed

5448-906 Generator Parts Speed Controller 2301A Speed

5466-336 WOODWARD generator set speed control board

9907-205 WOODWARD Speed Sensor Full Series

5437-418 WOODWARD generator set speed control board

8915-877 Controller debugger generator WOODWARD

5462-472 From Woodward, USA

5417-417 From Woodward, USA

9907-826 WOODWARD Speed Sensor Full Series

5461-292 From Woodward, USA

5405-819 From Woodward, USA

5432-157 WOODWARD generator set speed control board

5466-1047 Controller debugger generator WOODWARD

9907-361 From Woodward, USA

5464-346 WOODWARD 2301A Speed Control Controller

8440-2164 Generator Parts Speed Controller 2301A Speed

8440-1831 Controller debugger generator WOODWARD

9903-543 From Woodward, USA

8575-241 Controller debugger generator WOODWARD

5464-275 Controller debugger generator WOODWARD

5464-725 Generator Parts Speed Controller 2301A Speed