Description

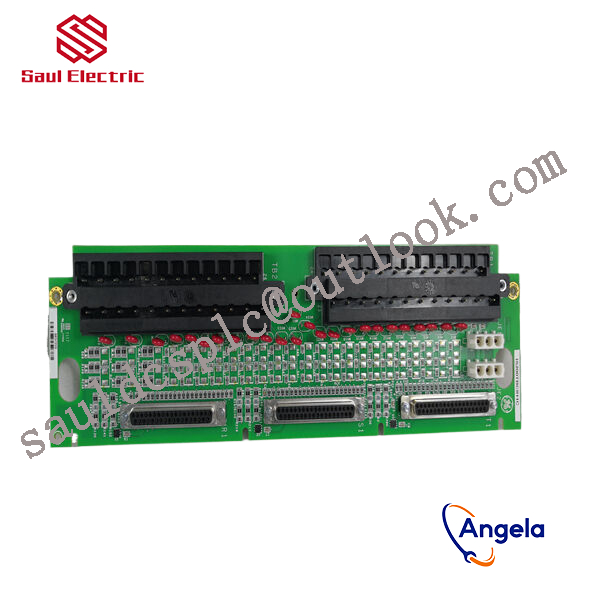

IS215WETAH1BB Product Introduction

The specific application scope of the product

will depend on the needs of system integration and industrial application, but generally speaking, this type of embedded controller module can be applied to the following categories:

manufacturing processes, etc.

monitoring and control system.

of the controller module, as well as the specific needs of the customer.

designed to manage gas or steam turbines.

It has a CIMPLICITY graphical interface and an HMI with software suitable for running heavy-duty turbines.

be installed at the bottom of the cabinet. For a small setup that is easy to serve a triple redundant system, up to three components can be installed side by side.

he board can operate within a temperature range of 0 to 65 degrees Celsius without the need for a fan for cooling. NFPA Class 1. This board can be used for two applications.

According to reports, ABB”s technical expertise and experience in many industries will be combined with Microsoft”s Azure intelligent cloud system and B2B engineering capabilities to create greater value for customers. Combined with ABB”s more than 70 million connected devices installed globally and more than 70,000 running control systems, ABB and Microsoft will join forces to create one of the world”s largest IIoT industrial cloud platforms.It is worth noting that IoT expert Guido Jouret (formerly general manager of Cisco’s IoT department) became the group’s chief digital officer on October 1, 2016. This marks that ABB is accelerating digital transformation and comprehensively building a new “Internet of Things+” ecosystem. ABB also hopes to obtain higher profits from this, and has proposed a financial target for 2015-2020 of pre-tax profit growth of 11%-16%.FANUCFANUC recently established the IoT platform Fanuc Intelligent Edge Link and Drive (FIELD), which uses NVIDIA artificial intelligence system. FIELD can realize the connection of machine tools, robots, peripheral equipment and sensors in the automation system and provide advanced data analysis to improve the production quality, efficiency, flexibility and equipment reliability in the production process – thereby improving the overall efficiency of the equipment ( OEE) and promote the improvement of production profits.The system can also improve robot productivity through artificial intelligence and bring autonomous learning capabilities to automated factory robots around the world. FANUC will use a series of GPUs and deep learning software designed and produced by NVIDIA to enable AI artificial intelligence to be used in clouds, data centers and embedded devices.When talking about the cooperation with FANUC, NVIDIA co-founder and CEO Jensen Huang said that the era of AI artificial intelligence has officially arrived. Through the deep learning function of GPU, it will stimulate a new wave of software learning and machine inference calculations. The most exciting of these is the ability of robots to understand their surroundings and interact with humans. NVIDIA is very happy to work with FANUC, the global leader in automated factories and robots, to build intelligent machines to benefit the future of mankind.It is reported that FIELD continues the success of the existing Fanuc ZDT (zero downtime function), which effectively combines Cisco cloud technology, IoT data collection software and point-to-point security. After connecting the robot through the use of an industrial Ethernet switch, it is then connected to Cisco”s UCS server – the system runs based on FANUC and Cisco”s ZDT data collection software. Automotive industry users can immediately realize reductions in downtime and cost savings after using the system.FIELD provides users and application developers with advanced machine learning and artificial intelligence capabilities and brings manufacturing to new heights of productivity and efficiency. Currently, FANUC has applied these new technologies to robotic bulk picking, production anomaly detection and fault prediction. Because FIELD combines artificial intelligence and cutting-edge computer technology, distributed learning is possible. The operating data of robots and equipment are processed in real time on the network, which also enables more intelligent coordination of production between various equipment, making complex production coordination that was previously difficult to achieve easily completed.In fact, many years ago, FANUC began to cooperate with Cisco to carry out the “non-stop” zero downTIme plan. In the plan, FANUC and Cisco will join forces to build an Internet of Things system that will allow FANUC to supervise every robot in the factory, predict abnormal conditions of the robots, and send more technicians to repair the robots before problems occur. So far, the program has tested 2,500 robots, including FANUC”s major customer GM General Motors. According to FANUC, the test program saved customers $38 million.YASKAWAAfter talking so much about the Internet of Things strategy of the industrial robot giant, let’s take a break here at Yaskawa and talk about the past.Midea and KUKA have officially received their marriage certificates, but you must know that as early as August 2015, Midea announced its robot strategy and established two joint venture subsidiaries with Japan”s Yaskawa Electric.The two subsidiaries are respectively for industrial robots and service robots, including Guangdong Yaskawa Midea Industrial Robot Co., Ltd. (Midea”s equity accounted for 49%) and Guangdong Midea Yaskawa Service Robot Co., Ltd. (Midea”s equity accounted for 60%).This shows that as early as 2015, Midea was actually “in love” with Yaskawa, but by 2016, she married Kuka.

IS220PDIOH1A High performance processor module GE

IS200TDBTH6A High performance processor module GE

IS200ERGTH1AAA GE power control board

DS200RTBAG1AHC I/O excitation redundant module GE

IS200SRTDH2A GE power control board

IS215GFOIH1A Processor/Controller Mark VI System

IS210BPPBH2BMD GE power control board

DS200DMCBG1AKG Gas turbine system Mark VI

IS230SNTCH4A From General Electric in the United States

IS200TRPAS1A High performance processor module GE

DS200PTCTG2BAA Processor/Controller Mark VI System

DS200DDTBG2A High performance processor module GE

IS210WSVOH1AE Gas turbine system Mark VI

DS200DCFBG1BNC Processor/Controller Mark VI System

IS200DSPXH2C Gas turbine system Mark VI

IS210AEPSG1B Gas turbine system Mark VI

IS200TPROH1C Gas turbine system Mark VI

DS215SDCCG1AZZ01A GE power control board

DS200TCQAG1BFE Processor/Controller Mark VI System

DS200TCCBG3B GE power control board

IS200WETBH1BAA Processor/Controller Mark VI System

DS200SLCCG3AGH Gas turbine system Mark VI

IS200SRLYH2AAA I/O excitation redundant module GE

DS200LDCCH1AGA From General Electric in the United States

IS215VCMIH2C GE power control board

IS2020LNPSG3A Processor/Controller Mark VI System

IS200TRPGH1B I/O excitation redundant module GE

8201-HI-IS High performance processor module GE

IS200REBFH1ABA I/O excitation redundant module GE

IS420YDIAS1B From General Electric in the United States

IS200CPFXG1A Processor/Controller Mark VI System

IS215UCVGM06A GE power control board

DS200PTBAG1BAA GE power control board

IS220PDIAH1A From General Electric in the United States

IS215VCMIH2BZZ01A Gas turbine system Mark VI

IS200ESELH1AAA GE power control board

IS420PUAAH1A High performance processor module GE

IS220UCSAH1A GE power control board

IS200TBTCH1B I/O excitation redundant module GE

IS200TRLYHIB I/O excitation redundant module GE

IS210SCSAS1A Processor/Controller Mark VI System

IS200EDCFG1B Gas turbine system Mark VI

IS200STCIH4A From General Electric in the United States

IS420ESWBH2A Processor/Controller Mark VI System

IS200IGDMH1A Processor/Controller Mark VI System

IS200EGPAG1BEC Gas turbine system Mark VI

DS200TCCBG3BDC From General Electric in the United States

IS220PPRAS1B High performance processor module GE

DS200CPCAG1ABB High performance processor module GE

IS215UCVEM06A Processor/Controller Mark VI System

IS200ISBBG1A Gas turbine system Mark VI

DS200QTBAG1A I/O excitation redundant module GE

DS200GGDAG1AHE Gas turbine system Mark VI

DS200PCCAG7A From General Electric in the United States

IS420PVIBH1B I/O excitation redundant module GE

IS200SCNVG1ADC GE power control board

IS200EXHSG3AEC GE power control board

IS200ESELH1A Gas turbine system Mark VI

IS200VRTDH1C High performance processor module GE

IS230SNRTH2A High performance processor module GE

IS210AEAAH1BBA Gas turbine system Mark VI

IS220PPROHIA I/O excitation redundant module GE

IS200DSPXH1DBC From General Electric in the United States

DS200PCCAG7ACB High performance processor module GE

IS210MACCH1A From General Electric in the United States

DS200VPBLG1A Processor/Controller Mark VI System

IS410STCIS6A Gas turbine system Mark VI

IS200VAICH1C I/O excitation redundant module GE

IS215ACLEH1B Processor/Controller Mark VI System

DS200TCPDG2BEC Processor/Controller Mark VI System

VMIVME-553IS High performance processor module GE

IS215UCVEH2AE High performance processor module GE

DS200ITXSG1ABB I/O excitation redundant module GE

IS220PVIBH1A Gas turbine system Mark VI

IS200TBCIS2CCD From General Electric in the United States

IS210AEBIH3B I/O excitation redundant module GE

DS200GDPAG1A GE power control board

IS215SECAH1A High performance processor module GE

IS200SRLYH2AAA Processor/Controller Mark VI System

IS200STAOH2AAA High performance processor module GE

IS420YDOAS1B Gas turbine system Mark VI

DS200DCFBG1BJB Gas turbine system Mark VI

IS200VSVOH1B I/O excitation redundant module GE

IS200HFPAG1A From General Electric in the United States

IS200ECTBG2A Gas turbine system Mark VI

IS410JPDEG1A GE power control board

IS200ERGTH1AAA High performance processor module GE

DS200TCRAG1ACC Processor/Controller Mark VI System

IS210AEBIH1A High performance processor module GE

DS200GLAAG1ACC GE power control board

IS220PAICH2B Gas turbine system Mark VI

IS215ACLEH1C Processor/Controller Mark VI System

DS200SDCCG1AGD High performance processor module GE

IS200VSVOH1B GE power control board

IS420YDIAS1B Processor/Controller Mark VI System

DS200SDCIG1A I/O excitation redundant module GE