Description

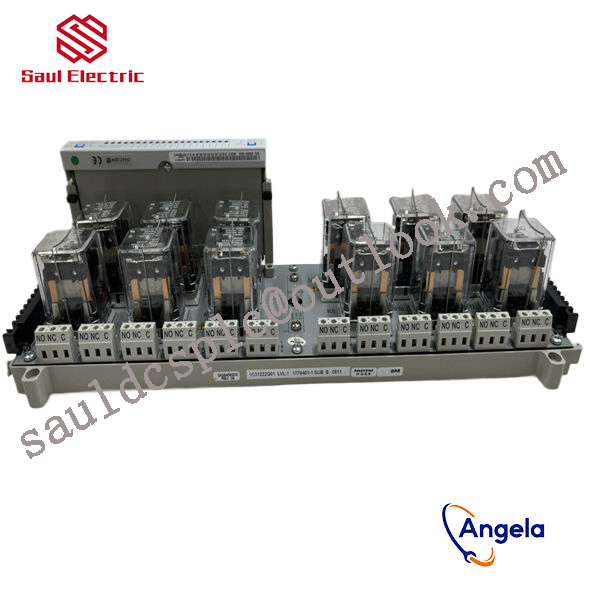

5D32123G02 Emerson redundant system output module

thereby controlling external devices or circuits.

CHANBAEK • Source: Network Compilation • June 5, 2024 18:25 • 6775 views

Join the discussion group

1. Introduction

In industrial automation and control system design, PID controller (proportional integral derivative controller) and PWM controller (pulse width modulation controller) are two commonly used control strategies. Although they can all achieve precise control of the system, there are significant differences in principles, applications, control characteristics, and other aspects. This article will provide a detailed comparison and analysis of PID controllers and PWM controllers to reveal their differences.

2、 Overview of PID Controller

PID controller is a feedback based control algorithm consisting of three control terms: proportional (P), integral (I), and derivative (D). It measures the difference (i.e. error) between the output value of the controlled object and the expected value, and then processes the error based on the three control terms P, I, and D to obtain the output of the controller. The principle of PID controller is based on error feedback regulation and has adaptive ability, which can dynamically adjust control parameters according to actual situations.

principle

The principle of PID controller is based on error feedback regulation. It first measures the output value of the controlled object, and then compares it with the expected value to obtain the error. Next, the error is processed based on proportional, integral, and derivative control terms to obtain the output of the controller. Among them, the proportional control term is proportional to the error and is used to quickly reduce the error; The integral control term is mainly used to eliminate accumulated errors and make the system more stable; The differential control term adjusts the output of the controller based on the rate of error change, making the system response faster and reducing overshoot.

responsible for processing signals from on-site sensors or driving actuator actions. For example, they may need to cooperate with devices such

as BANNER travel switch T30UIPB to receive their transmitted position signals; Or by controlling components such as Burkert solenoid valve 00131421, the on/off of fluid media can be precisely managed.

these modules integrate more complex logic processing capabilities. The core task of a pressure switch is to detect whether the pressure

has reached a preset threshold and output a switch signal. Its function is highly specific and fixed. And modules 5D32123G02 and 1

C31219G01 have the ability to comprehensively judge multiple such switch signals and transmitter signals (such as transmitter 1066-P-HT-60),

and output complex control instructions according to internal logic.