Description

- 32-bit DSP digital control mode

- Low vibration, low noise, low power consumption

- Maximum output current 3A/phase

- Adopting CAN bus and supporting standard CANopen communication protocol, it can load up to 127 devices

- Supports three modes: protocol position control, speed control, and periodic position control

- Current setting, subdivision, motor start stop control, and real-time monitoring of motor operation can be achieved through the bus

- 2-channel optoelectronic isolation programmable input interface

medical equipment, various types of robots, robotic arms, automated production lines, and various CNC machine tools.

B&R ABB robots empower flexible manufacturingAt this IAS, B&R demonstrated a new flexible manufacturing production line that integrates ABB robot and SuperTrak. The two ABB robots are a joint robot and a SCARA robot, which together with SuperTrak complete synchronous processing and CNC interpolation synchronization. , fluctuation suppression and other difficult actions, reflecting the perfect synergy between the robot and the conveyor system. SuperTrak has been put into production in many domestic production lines. It is very helpful in shortening the production cycle and reducing the switching time of production orders in automotive electronics assembly and lithium battery assembly.SuperTrak represents the digitization of the production line that goes deep into the execution layer. Traditional mechanical conveying systems cannot be flexibly adjusted according to software, while SuperTrak uses electromagnetic technology, motion control (CNC and robots), and software technology to enable flexible changes in the production line. Can be defined at the software level and adjusted to meet flexible production changing needs.Another set of ACOPOStrak is a more flexible production organization. SuperTrak is suitable for assembly lines with sequential logical processing, while ACOPOStrak is suitable for production scenarios that require shunting and converging. This IAS also exhibited a set of smallest unit ACOPOStrak systems. .OPC UA TSN – the foundation of digital connectivityAt this IAS, B&R also exhibited their OPC UA TSN system. A set of OPC UA TSN demonstration systems also attracted a lot of attention from the audience. OPC UA and TSN are the key technologies to realize the industrial Internet. TSN solves It solves the problem of IT non-periodic and OT periodic data transmission on the same network, while OPC UA solves the problem of semantic interoperability in heterogeneous networks. Currently, OPC UA has become an IEC and Chinese national standard, and is performing equipment level interconnection. , factory vertical interconnection and end-to-end connection with design, management, and operation software play a key role in semantic specification.B&R is an active promoter of OPC UA TSN technology. It has now fully integrated OPC UA in its control system, and TSN”s I/O nodes have also entered the testing stage. It is expected that batch products will be available in the first quarter of next year. will be put into the market.

XV-432-57CQB-1-10-PLC-SET Intelligent operation control system

XP-DVI-12T-10 Capacitive touch screen and resistive touch screen

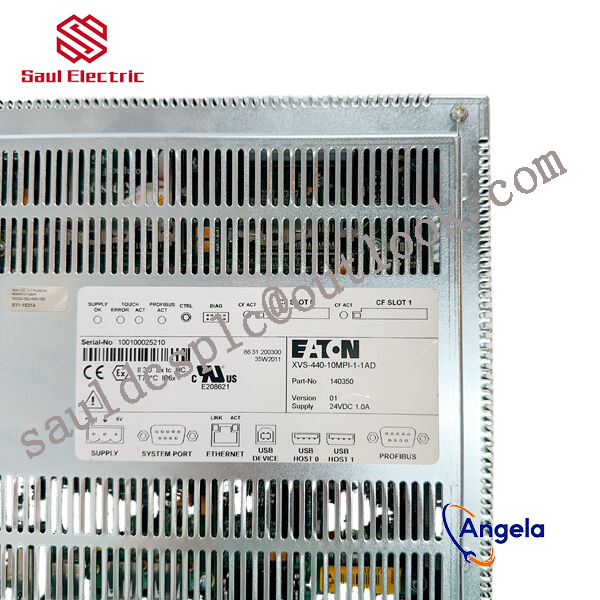

xv-440-10tvb-1-20 EATON HMI Human Machine Interface

SW-MXPRO Intelligent operation control system

MC2-442-57CQB-1-1H-2 EATON HMI Human Machine Interface

XN-KO/13 Capacitive touch screen and resistive touch screen

XV-303-15-C00-A00-1B Eaton human-machine touch screen

XV-DVI-GTI-12-000 Intelligent operation control system

XV-440-10TVB-X-13-1 EATON HMI Human Machine Interface

XV-442-57CQB-1-2AIVAR15 Human Machine Interaction

XP-301-12T-10 EATON Touch Panel

XV-102-B3-35TQR-10-PLC Human Machine Interaction

XV-442-57CQB-1-1C Human Machine Interaction

5485KPMPP5000 Capacitive touch screen and resistive touch screen

92-02123-00 EATON HMI Human Machine Interface

XV-303-10-C00-A00-1C Human Machine Interaction

MH2-342-57EIB-1-20 EATON Touch Panel

XN-2DO-R-NC Intelligent operation control system

XV-230-57CNN-1-10 Capacitive touch screen and resistive touch screen

XV-442-57cQB1-1W Human Machine Interaction

XV-432-57CQB-1-10-PLC Eaton human-machine touch screen

XN-P3T-SBB Intelligent operation control system

XV-442-57CQB-1-1AB Intelligent operation control system

XV440-10TVB-1-10 Eaton human-machine touch screen

MS2-440-57MPI-1-10 Human Machine Interaction

XV-DVI-GTR-12-000 Capacitive touch screen and resistive touch screen

XN-P4T-SBBC-B EATON HMI Human Machine Interface

MS2-440-57MPI-1-10 Intelligent operation control system

OS-HDU-A7-S EATON HMI Human Machine Interface

XN-1CNT-24VDC EATON Touch Panel

XN-KO/15 Intelligent operation control system

XV-430-10TVB-1-10 EATON HMI Human Machine Interface

MC2-430-10TVB-1-10 Eaton human-machine touch screen

XV-102-B0-35TQR-10-PLC EATON Touch Panel

XV-252-57CNN-1-1AE EATON HMI Human Machine Interface

XT-MEM-CF32M-01 EATON HMI Human Machine Interface

XV-442-57CQB-1-2AI EATON Touch Panel

XV-303-70-B00-A00-1C EATON HMI Human Machine Interface

XV-442-57CQB-1-1W EATON Touch Panel

XVH-330-57CAN-1-10 EATON Touch Panel

XV-152-D8-57TVRC-10 EATON HMI Human Machine Interface

MC2-442-57CQB-1-1D EATON HMI Human Machine Interface

XN-WEW-35/2-SW Human Machine Interaction

XN-4DI-24VDC-N Human Machine Interaction

XN-GW-PBDP-1.5MB Capacitive touch screen and resistive touch screen

XVM-430-65TVB-1-11 Human Machine Interaction

XV-102-D8-70TWRC-10 Capacitive touch screen and resistive touch screen

XVH-340-57CAN-1-50 Capacitive touch screen and resistive touch screen

MC2-440-10TVB-1-2A Intelligent operation control system

XN-QV/8 Intelligent operation control system