Description

- 32-bit DSP digital control mode

- Low vibration, low noise, low power consumption

- Maximum output current 3A/phase

- Adopting CAN bus and supporting standard CANopen communication protocol, it can load up to 127 devices

- Supports three modes: protocol position control, speed control, and periodic position control

- Current setting, subdivision, motor start stop control, and real-time monitoring of motor operation can be achieved through the bus

- 2-channel optoelectronic isolation programmable input interface

medical equipment, various types of robots, robotic arms, automated production lines, and various CNC machine tools.

Data shows that the global robot market size is US$25 billion (approximately 160 billion yuan) in 2020; this number is expected to grow to US$260 billion (approximately 1.7 trillion yuan) by 2030.For a long time, managers of many companies have claimed to realize operational automation, but they have not achieved much substantive results. But now, the COVID-19 epidemic has changed everything, prompting them to accelerate their investment in this field. A huge wave of automation is coming.Research firm Robo Global predicts that by the end of 2021, the global installed base of industrial robots will exceed 3.2 million units, double the number in 2015. The global industrial robot market is expected to rise from US$45 billion in 2020 to US$73 billion in 2025.Nigel Wass, CEO of Publicis Sabent, said that companies are not just trying to return to the pre-epidemic operating model, but are completely restructuring the way they operate.A new survey from think tank McKinsey Global Research found that about two-thirds of businesses around the world are doubling down on automation.”We had a head start during the pandemic,” said Michael Schick, head of U.S. operations at Japanese robot maker Fanuc. As supply chains have been hit, manufacturers have been forced to find ways to be more flexible. Today”s most dexterous robots can pick very delicate things, such as strawberries, he said. Market demand for robots developed by Fanuc has surged, especially in industries such as e-commerce that have been greatly boosted by the epidemic.

MC2-440-12TSB-1-21 Human Machine Interaction

XN-P4S-SBBC Human Machine Interaction

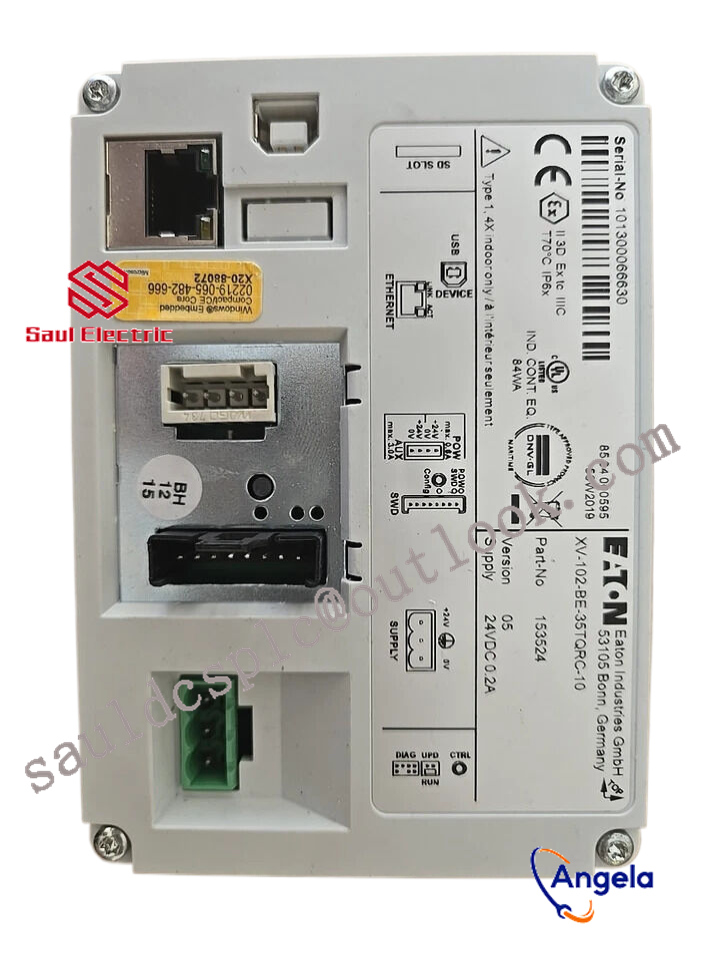

XV-102-B8-35TQR-10-PLC Intelligent operation control system

XV-102-D6-57TVRC-1K Human Machine Interaction

XV-102-A0-35MQR Intelligent operation control system

XV-440-10TVB-1-2I Intelligent operation control system

XVS-430-10MPI-1-10 Capacitive touch screen and resistive touch screen

XN-ANBZ-SW Human Machine Interaction

XV-232-57BAS-1-10 EATON HMI Human Machine Interface

XN-ABPL Eaton human-machine touch screen

XV-460-15TXB-1-50 EATON Touch Panel

XN-S6T-SBCSBC EATON HMI Human Machine Interface

XV-DVI-GTI-10-000 EATON Touch Panel

XV-430-12TSB-1-10 EATON HMI Human Machine Interface

XVS-460-15MPI-1-10 Human Machine Interaction

XN-KO/10 Human Machine Interaction

XC-CPU202-EC4M-8DI-6D0-XV Eaton human-machine touch screen

XV-442-57CQB-1-1U Intelligent operation control system

MV4-690-TA2-XX3 EATON Touch Panel

MC2-440-12TSB-1-10 EATON HMI Human Machine Interface

XN-1RS232 Eaton human-machine touch screen

XV-303-70-B00-A00-1B EATON Touch Panel

XN-ANBZ-GN EATON Touch Panel

XV-230-57CNN-1-10(OS/CF) EATON HMI Human Machine Interface

XVC-601-GTI-15-IBS-GOSS Capacitive touch screen and resistive touch screen

XN-KO/10 EATON Touch Panel