Description

- 32-bit DSP digital control mode

- Low vibration, low noise, low power consumption

- Maximum output current 3A/phase

- Adopting CAN bus and supporting standard CANopen communication protocol, it can load up to 127 devices

- Supports three modes: protocol position control, speed control, and periodic position control

- Current setting, subdivision, motor start stop control, and real-time monitoring of motor operation can be achieved through the bus

- 2-channel optoelectronic isolation programmable input interface

medical equipment, various types of robots, robotic arms, automated production lines, and various CNC machine tools.

What are the advantages of ABB robots in plastic production?Manufacturer Array Plastics has produced plastic parts and assemblies for customers in the automotive and industrial sectors in Europe and Mexico since 1992. Now Array Plastics has introduced ABB robots, hoping to use industrial robots to optimize and improve operations to speed up workpiece switching, meet a large number of customized production needs, and also improve the flexibility and efficiency of the core injection molding process.The plastic processing market is becoming more and more complex and competition is intensifying. As the trend of short-cycle and small-batch production gradually emerges, the market has also put forward higher requirements for production flexibility. While ensuring high quality, producing molds and products with more complex shapes and more types has become the focus of plastic manufacturers. Flexible ABB robots use new production cells, program and install new parts, which can speed up production and increase flexibility. Working closely with plastics processors, Industrial Robots offers a comprehensive product portfolio for the plastics and rubber industry.ABB robots combine the flexibility and quality required for many specialty products in the production process, including technical plastic parts, optical lenses and light guides, ultrasonic and vibration welding , automated assembly parts and physical vapor deposition (PVD) vacuum metal coating. The ability to change tools easily and quickly is very important. More and more production lines rely on robots to improve production processes and increase efficiency, ensuring quality while also meeting the needs of different customers.Recently, power and automation technology giant ABB India said its board of directors approved the proposal to sell the company”s solar inverter business to Marici Solar India for Rs 1.006 billion. Solar energy is a good choice, and people have begun to vigorously develop solar power generation.The company said in a statement that the business transfer will be effective from April 1. Marici Solar India is a wholly-owned subsidiary of Italian Fimer SpA in India.Data shows that in fiscal 2019, ABB India”s solar inverter business had a turnover of 6.64 billion rupees, accounting for approximately 9% of the total turnover.ABB is a leader in electrification, industrial automation, motion, robotics and discrete automation. When the technology for human beings to utilize solar energy is very mature, there will be endless energy for society to use, and now researchers need to work harder to study new technologies.

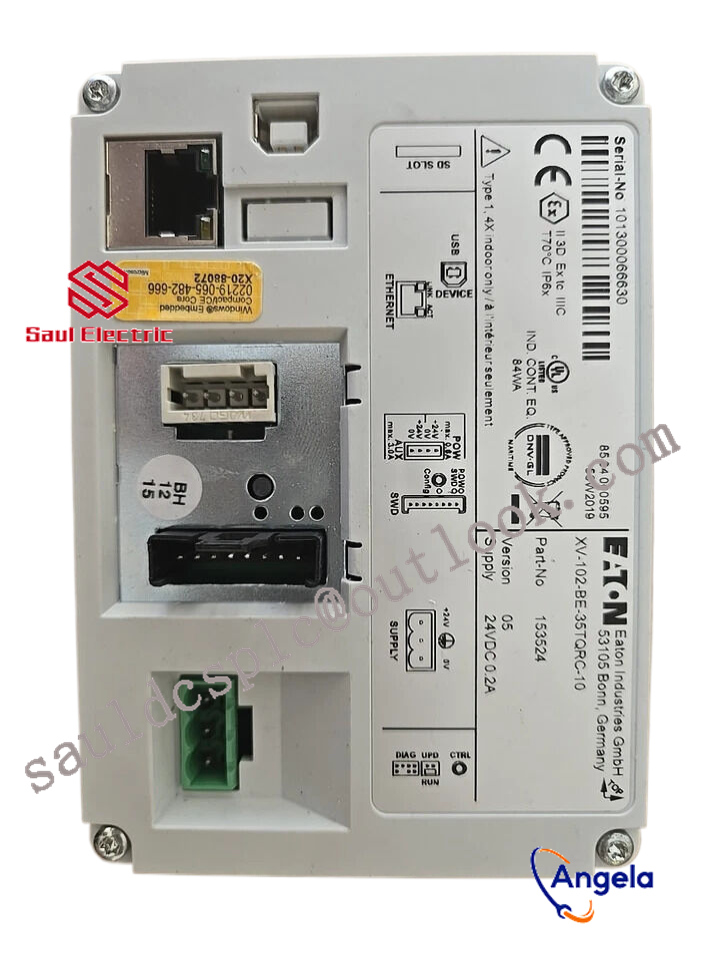

XN-2DO-R-NO EATON Touch Panel

MV4-690-TA2-XX0 EATON Touch Panel

XNE-8DO-24VDC-0.5A-P Intelligent operation control system

XVC-101-C192K-K82-002 Intelligent operation control system

XVS-440-57MPI-1-1Z EATON Touch Panel

MS2-430-57MPI-1-10 Human Machine Interaction

XVS-430-57MPI-1-1S EATON Touch Panel

OS-FLASH-A2-S Human Machine Interaction

XVS-440-12MPI-1-10 Intelligent operation control system

MEMORY-SD-A1-S Capacitive touch screen and resistive touch screen

XN-P3S-SBB Intelligent operation control system

XV-102-D6-70TWRC-10 Human Machine Interaction

XN-QV/7 EATON Touch Panel

XN-PLC-CANOPEN EATON Touch Panel

MC2-442-57CQB-1-30 EATON HMI Human Machine Interface

XN-1CNT-24VDC Intelligent operation control system

MC2-442-57CQB-1-2A Capacitive touch screen and resistive touch screen

XV-DVI-GTI-15-000 EATON Touch Panel

XVS-460-57MPI-1-10 Human Machine Interaction

MICRO-DRIVE-340MB EATON Touch Panel

XVS-440-10MPI-1-1AD EATON HMI Human Machine Interface

XV-102-B4-35MQR-10-PLC Intelligent operation control system

XN-S4T-SBBS-CJ EATON Touch Panel

XVC-601-GTI-10-V1-015 EATON HMI Human Machine Interface

MEMORY-CF-BRS-3 Capacitive touch screen and resistive touch screen

XNE-16DI-24VDC-P Intelligent operation control system

XV-430-12TSB-1-10-PLC Eaton human-machine touch screen

XN-GWBR-DNET EATON Touch Panel

XVC-601-GTI-10-DPM-V1-000 Intelligent operation control system

XV-102-B3-35TQR-10-PLC EATON HMI Human Machine Interface

MC2-430-12TSB-1-11 EATON HMI Human Machine Interface

XN-4AI-U/I Capacitive touch screen and resistive touch screen

XVS-440-10MPI-IV Human Machine Interaction

XP-702-D0-12TXI-10 EATON Touch Panel

XVS-460-57MPI-1-1E Capacitive touch screen and resistive touch screen

XN-ANBZ-BL Human Machine Interaction

xv-102-b5-35-tqr-10-plc Eaton human-machine touch screen

XN-KO/6 Human Machine Interaction

XV-230-57MPN-1-10(OS/CF) Human Machine Interaction

XN-1AI-U(-10/0…+10VDC) Capacitive touch screen and resistive touch screen

XV-102-A5-35MQR-10 Human Machine Interaction

MH2-330-57CAN-1-10 EATON Touch Panel

XN-ANBZ-GN EATON HMI Human Machine Interface

XV-252-57CNN-1-1K Eaton human-machine touch screen

XN-GWBR-CANOPEN Intelligent operation control system

5485KPMPP5000 Human Machine Interaction

SW-EPAM Human Machine Interaction

XN-S6T-SBCSBC EATON Touch Panel

XP-503-15-A10-A01-1V EATON HMI Human Machine Interface