Description

- 32-bit DSP digital control mode

- Low vibration, low noise, low power consumption

- Maximum output current 3A/phase

- Adopting CAN bus and supporting standard CANopen communication protocol, it can load up to 127 devices

- Supports three modes: protocol position control, speed control, and periodic position control

- Current setting, subdivision, motor start stop control, and real-time monitoring of motor operation can be achieved through the bus

- 2-channel optoelectronic isolation programmable input interface

medical equipment, various types of robots, robotic arms, automated production lines, and various CNC machine tools.

Coke oven is a key in the coking industry. The temperature in the oven directly affects the quality of the refining coke. Therefore, we must ensure that the temperature in the oven is stable within a reliable range. Therefore, we must control the pressure in the coke oven flue and gas main pipe. We adopt a composite control method, that is, feedforward plus feedback/manual switching to achieve control requirements. The liquid level in the elution benzene condensate storage tank, the temperature at the top of the ammonium distillation tower and the pH value of the ammonium water are automatically adjusted. Since the SP value (set value) of many adjustment loops is an uncertain number , need to be based on different requirements in different periods; in the design of PID adjustment and manual/automatic switching, we designed the SP to track the PV when manual, and adjust the process value according to the SP value during automatic switching, so that when the operator switches from manual Switch the adjustment process value to automatic and you can adjust it immediately with this process value. It is conducive to operators to further explore ways to improve work efficiency.On the operation interface of the operator station, trend charts of important variables such as “ammonium distillation tower bottom pressure” and “regeneration tower liquid level” are created, which is helpful for operators to intuitively observe the changing trends of important data. We use the signal sequence function to record the changing process of each operation. Its fastest scanning period is two milliseconds, so that we can clearly remember the changing sequence of data. When an accident occurs, we can refer to these data to analyze the cause of the accident. . We have also created a database to cumulatively record important variables in the process of “coal preparation”, “coke screening”, “tank area”, etc. Enterprises can analyze the production process based on the data, optimize the production process, and continuously improve efficiency.The OPC standard software interface is designed in the system, which provides the basis for the enterprise”s on-site data management. At the same time, it provides guarantee for enterprises to realize information management.7. SummaryNow the plant has been put into production. According to the design requirements, the entire system is designed to produce 1 million tons of coke per year. The DCS control system provides guarantee for achieving this goal. The ABB AC800F distributed control system operates stably and reliably, and at the same time brings convenience to the enterprise”s information management. Practice has proven that the DCS control system has made contributions to improving labor productivity, improving product quality, and avoiding accidents. It has brought considerable economic benefits to the enterprise and achieved user satisfaction.

XN-GW-PBDP-12MB-STD Intelligent operation control system

XC-CPU201-EC256K-8DI-6DO Human Machine Interaction

XCC-672-DVI-V1-000 EATON HMI Human Machine Interface

OS-HDU-A4-S Intelligent operation control system

MH2-330-57CAN-1-10 Eaton human-machine touch screen

XN-1AI-I(0/4…20MA) EATON HMI Human Machine Interface

XVM-450-65TVB-1-11 Human Machine Interaction

MC2-442-57CQB-1-10 Capacitive touch screen and resistive touch screen

MC2-440-10TVB-1-2L Eaton human-machine touch screen

XN-ABPL EATON Touch Panel

XV-303-15-C02-A00-1B Human Machine Interaction

XV-102-B5-35TQR-10-PLC Eaton human-machine touch screen

MC2-440-10TVB-1-2I EATON Touch Panel

XV-102-A5-35MQR-10 Eaton human-machine touch screen

XVC-601-GTI-12-DPM-V1-000 Intelligent operation control system

XV-430-10TVB-1-10-PLC Human Machine Interaction

XN-2AI-I(0/4…20MA) EATON Touch Panel

MC2-440-10TVB-1-2L EATON HMI Human Machine Interface

XV-460-57TQB-1-50-PLC Intelligent operation control system

MC2-440-12TSB-1-20 Human Machine Interaction

XV-152-D8-10TVR-10 EATON Touch Panel

XVC-101-C192K-K82 Capacitive touch screen and resistive touch screen

MC2-442-57CQB-1-2G Capacitive touch screen and resistive touch screen

XN-2DO-R-NC EATON Touch Panel

MC2-442-57CQB-1-31 EATON HMI Human Machine Interface

XV-102-B8-35MQR-10-PLC Human Machine Interaction

XN-P4T-SBBC-B Eaton human-machine touch screen

XV-152-D8-84TVR-10 Human Machine Interaction

XN-S6S-SBBSBB Capacitive touch screen and resistive touch screen

XP-DVI-19T-10 Intelligent operation control system

XN-4AI-U/I Eaton human-machine touch screen

XT-232-PT-5-01 EATON Touch Panel

XV-102-A2-35MQR-10 Human Machine Interaction

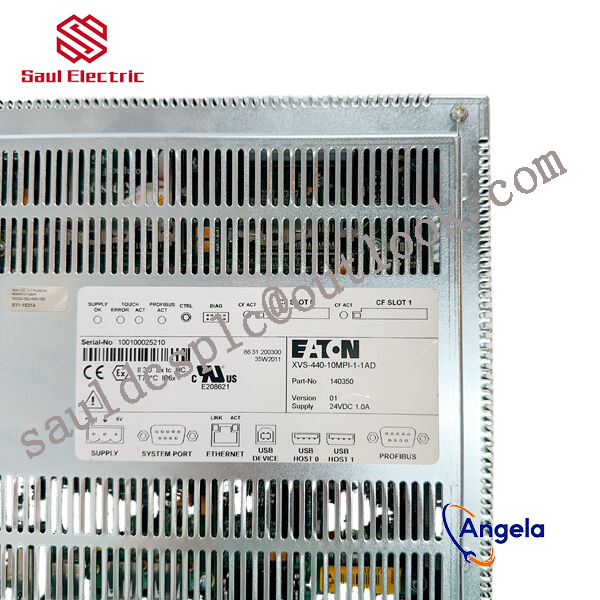

XVS-440-10MPI-1-1AF EATON Touch Panel

XN-KO/12 Intelligent operation control system

XV-460-57TQB-1-50 Intelligent operation control system

XVC-101-C192K-K82 EATON Touch Panel

XV-232-57BAS-1-10 EATON Touch Panel

XN-S4S-SBBS-CJ Human Machine Interaction

XVC-601-GTI-12-DPM-V1-000 EATON Touch Panel

XN-2DO-R-NO Capacitive touch screen and resistive touch screen

8922-RB-IS EATON HMI Human Machine Interface

OS-FLASH-A1-L EATON Touch Panel

XV-460-15TXB-1-10 Intelligent operation control system

XVC-101-C192K-K82-002 Eaton human-machine touch screen

XP-702-C0-84TSI-10 Human Machine Interaction

OS-HDU-A4-S Capacitive touch screen and resistive touch screen

XN-ANBZ-RT EATON HMI Human Machine Interface

XVH-340-57CAN-1-10 Eaton human-machine touch screen

XV-102-D8-57TVR-10 Eaton human-machine touch screen