Description

- 32-bit DSP digital control mode

- Low vibration, low noise, low power consumption

- Maximum output current 3A/phase

- Adopting CAN bus and supporting standard CANopen communication protocol, it can load up to 127 devices

- Supports three modes: protocol position control, speed control, and periodic position control

- Current setting, subdivision, motor start stop control, and real-time monitoring of motor operation can be achieved through the bus

- 2-channel optoelectronic isolation programmable input interface

medical equipment, various types of robots, robotic arms, automated production lines, and various CNC machine tools.

ConclusionFrom the official websites of several parallel robots and other channels, we learned that many Fortune 500 companies around the world use their robots, and the mid-to-high-end market for parallel robots is firmly occupied by them.As China”s industrial robot market demand continues to expand, major robot manufacturers have entered China to seize the market, and the same is true in the field of parallel robots.Traditional robot companies such as ABB and FANUC have entered China very early, and Germany”s BLIZX also began to enter China in 2017. These foreign brands have quickly occupied China”s mid-to-high-end market by virtue of their own technological advantages and successful application experience in Europe and the United States. After the patent for parallel robots expired in 2012, a number of parallel robot manufacturers have emerged in China in recent years. They have taken advantage of low cost to seize part of the mid-to-low-end market. However, they still lack core components and technologies, so in For a long time in the future, it will be in a state of catching up with European and American manufacturers. In the “17th China Electrical Industry Top 100” list announced on December 11, ABB has 8 local companies successfully selected, and once again won the “Top 10 Competitiveness of China”s Electrical Industry” and “Top 10 Innovation of China”s Electrical Industry” “Strong” two important individual awards, demonstrating the strong strength of continuing to lead the development of electrical and manufacturing industries in the new wave of industrial revolution. 8 ABB companies were selected into the “17th China Electrical Industry Top 100″ The “Top 100 Chinese Electrical Industry” selection was initiated in 2000 by the “Electrical Times” magazine affiliated with the China Machinery Industry Information Research Institute. It has been successfully held for 17 times so far. It is an annual inventory and reference coordinate for the development of China”s electrical industry. Zhou Baodong, deputy secretary of the Party Committee of the Machinery Industry Information Research Institute, said: “With the emergence of a new round of scientific and technological revolution, the electrical equipment manufacturing industry is gradually transforming from factor-driven to innovation-driven, and from traditional manufacturing to intelligent manufacturing. In the current pace of the national economy, Facing many challenges such as entering the “new normal”, Chinese electrical companies, especially the top 100 companies, are pioneering, innovating and working hard. While maintaining the growth of main business income, they have further accelerated the improvement of the company”s comprehensive strength and achieved success. A difficult achievement.” At present, the new generation of information technology continues to integrate and penetrate into fields such as power, industry, transportation, and infrastructure. Digitalization and intelligence have become important directions for industrial development and transformation and have brought new opportunities. As a global industrial technology leader and digital leader, more than 55% of the ABB Group”s sales revenue comes from software and digital equipment. Currently, based on more than 70 million connected devices installed around the world and more than 70,000 running control systems, ABB We are using our rich industry experience to further develop unique digital solutions and further tap the potential of the digital field through continuous innovation. In 2016, the total number of industrial robots manufactured by ABB in China exceeded 50,000 units, and a second dedicated production line for servo motors was built in Shanghai to meet the demand for this key component in the rapidly growing robot market; at the same time, ABB also launched robots Collaborative solution SafeMove2, as well as foundry robot IRB1200 Casting Expert II generation, compact robot IRB1660ID and other new robot products support the transformation and upgrading of various industries with more digital and intelligent products and solutions, helping my country transform from a “manufacturing power” to a The transformation of “manufacturing power”. Green energy saving is also one of ABB”s key areas of technological innovation. Faced with the increasing popularity of electric vehicles, ABB launched the Terra 53 Ze electric vehicle fast DC charger specially developed for the Chinese market in 2016. It has an output power of 50 kilowatts and can meet the needs of highway charging stations, car 4S stores, and gas stations. and busy transportation hub charging stations and other commercial users’ charging needs, assisting the construction of electric vehicle charging infrastructure and sustainable transportation development; ABB also launched its first dedicated turbocharger for marine auxiliary engines to support the shipping industry in reducing fuel consumption and operations cost; as well as scalable modular “plug and play” microgrid solutions and multiple new inverters to promote the development and grid integration of renewable energy.

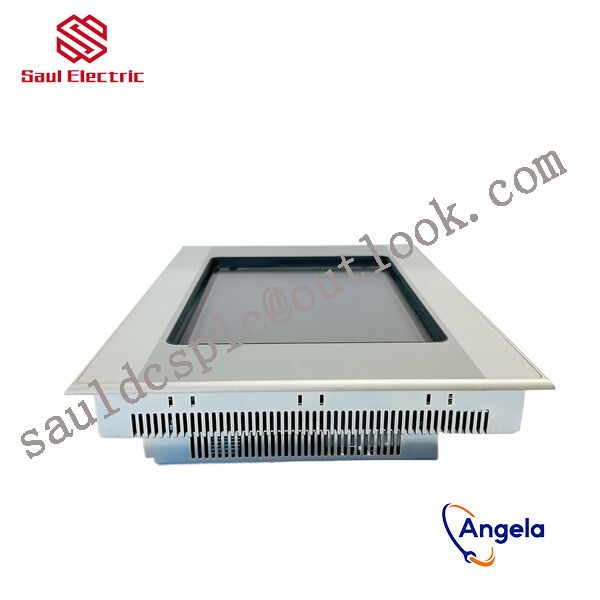

MC2-440-12TSB-1-1K Capacitive touch screen and resistive touch screen

XP-503-15-A10-A00-1B Intelligent operation control system

XVC-601-GTI-10DPM-V1-000 Capacitive touch screen and resistive touch screen

MC2-440-10TVB-1-1F EATON Touch Panel

XVC-601-GTI-10DPM-V1-000 EATON HMI Human Machine Interface

XCC-601-DVI-DPM-V1-000 Eaton human-machine touch screen

XV-252-57MPN-1-1AH Intelligent operation control system

XVS-460-57MPI-1-1EVAR10 Intelligent operation control system

STARTERKITECOSYSTEMCAN EATON Touch Panel

XV-102-B8-35MQR-10-PLC EATON HMI Human Machine Interface

XV-432-57CQB-1-10-PLC Human Machine Interaction

XV-102-D8-57TVR-10 EATON HMI Human Machine Interface

STARTERKITXV-200COLORHMICAN Eaton human-machine touch screen

MC2-440-10TVB-1-50 Intelligent operation control system

XV-303-10-C00-A00-1B Human Machine Interaction

XV-102-B6-35MQR-10-PLC EATON HMI Human Machine Interface

XN-16DO-24VDC-0.5A-P Human Machine Interaction

XV-152-D6-57TVR-10 Human Machine Interaction

XV-152-D6-84TVRC-10 Intelligent operation control system

XN-2DO-24VDC-2A-P Eaton human-machine touch screen

MC2-442-57CQB-1-30 EATON Touch Panel

XVC-601-GTI-10-V1-010 Human Machine Interaction

XN-KO/12 EATON HMI Human Machine Interface

MC2-430-10TVB-1-11 Intelligent operation control system

XN-GW-DNET Intelligent operation control system

XV-102-D6-57TVRC-1K EATON HMI Human Machine Interface

XN-32DI-24VDC-P EATON Touch Panel

MC2-440-10TVB-1-2L Capacitive touch screen and resistive touch screen

XV-430-12TSB-1-10-PLC Human Machine Interaction

5485KPMPP5000 EATON Touch Panel

XP-702-C0-84TSI-10 Capacitive touch screen and resistive touch screen

XN-ANBZ-SW Intelligent operation control system

XT-SUB-D-SUB-D Human Machine Interaction

XVS-450-57MPI-1-10 Capacitive touch screen and resistive touch screen

MC2-442-57CQB-1-2G Human Machine Interaction

XT-232-PT-5-01 EATON HMI Human Machine Interface