Description

- 32-bit DSP digital control mode

- Low vibration, low noise, low power consumption

- Maximum output current 3A/phase

- Adopting CAN bus and supporting standard CANopen communication protocol, it can load up to 127 devices

- Supports three modes: protocol position control, speed control, and periodic position control

- Current setting, subdivision, motor start stop control, and real-time monitoring of motor operation can be achieved through the bus

- 2-channel optoelectronic isolation programmable input interface

medical equipment, various types of robots, robotic arms, automated production lines, and various CNC machine tools.

Recently, global robotics giant ABB announced its third quarter financial report for 2021 : Order volume was US$7.9 billion, an increase of 29% year-on-year and an increase of 26% on a comparable basis.Sales revenue was US$7 billion, an increase of 7% year-on-year and an increase of 4% on a comparable basis.Gross profit was US$2.3 billion, a year-on-year increase of 25%Operating EBITDA was US$1.062 billion, with a profit margin of 15.1%Net profit attributable to ABB was US$652 million, down 86%Cash flow from operating activities was $1.104 billion, and cash flow from operating activities from continuing operations was $1.119 billion.It is worth noting that although ABB achieved good data in the third quarter, it has declined overall compared with the second quarter. Order revenue fell by 2.6% compared with Q2, and gross profit margin fell by 7.6% compared with Q2. In line with the trend of industry growth slowing down in the second half of the year.ABB Group CEO Luo Biang said: The third quarter was mixed. On the one hand, high demand drove strong order growth; on the other hand, the tight supply chain had a larger-than-expected impact on sales revenue. Nonetheless, we grew underlying operating earnings and margins, had strong cash flow, made progress on our business mix realignment, and completed a number of important product launches.Third quarter robotics and discrete automation performance As the leader in industrial robots, ABB”s robot orders grew rapidly in the third quarter, but its sales revenue was not ideal. The financial report shows that for the robot and discrete automation business, the order volume in the third quarter was US$935 million, a year-on-year increase of 30% (a comparable increase of 26%), but the sales revenue was only US$813 million, a year-on-year increase of 1% (a comparable decrease of 3%). In terms of orders. ABB said that customer activity increased in all market segments in the third quarter, with the strongest growth in machine automation orders, followed by the general industry, and the consumer-oriented service robot segment; at the same time, all regions improved at a double-digit rate , among which the Americas and Europe exceeded the AMEA region, including a 17% year-on-year increase in orders from China (comparable 10%).In terms of income. The decline in comparable revenue was due to the combined impact of parts shortages and steady advances in robotics, resulting in machine automation facing delayed customer deliveries, due to a conscious effort to support long-term profitability by reducing exposure to the automotive systems business, while The automotive systems business is currently facing a shrinking order backlog.In terms of profit. The operating EBITA (earnings before interest, taxes, depreciation and amortization) of the Robotics and Discrete Automation business in the third quarter was US$90 million, a year-on-year increase of 18%, and the profit margin reached 11.1%. This was attributed to the reduction of automotive system sales, increased service business share and efficiency. measure.

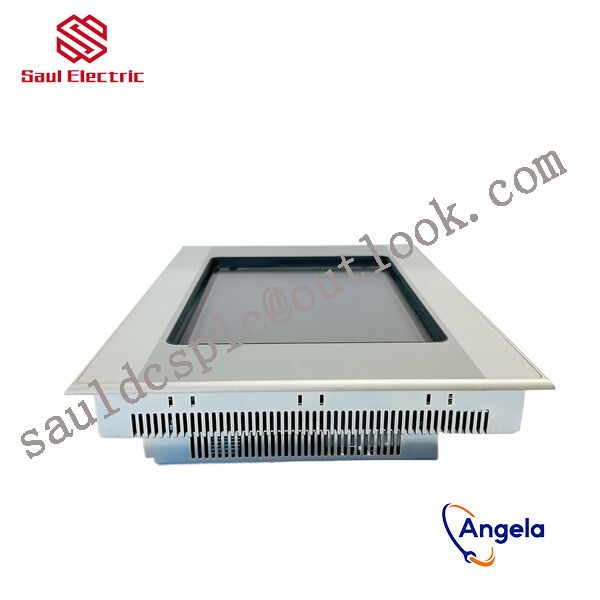

XV-152-D8-10TVR-10 Intelligent operation control system

XV-440-10TVB-1-20 Human Machine Interaction

MEMORY-CF-BRS-3 Eaton human-machine touch screen

XN-KO/2 Capacitive touch screen and resistive touch screen

XV-102-D8-57TVRC-10 Eaton human-machine touch screen

MV4-690-TA2-XX0 Intelligent operation control system

MS2-430-12MPI-1-10 Capacitive touch screen and resistive touch screen

MC2-442-57CQB-1-20 EATON Touch Panel

XV-102-B2-35TQR-10 Intelligent operation control system

XVC-601-GTI-10-V1-010 Eaton human-machine touch screen

XV-303-10-CE0-A00-1C EATON Touch Panel

XV-440-10TVB-1-1AB EATON Touch Panel

SW-CAN-MONITOR Eaton human-machine touch screen

XC-CPU202-EC4M-8DI-6D0-XV Intelligent operation control system

XN-ANBZ-RT EATON Touch Panel

XN-ANBZ-RT/BL-BED EATON Touch Panel

XV-303-15-C02-A00-1B EATON Touch Panel

XV-102-D6-70TWRC-10 EATON HMI Human Machine Interface

XN-B3S-SBB Intelligent operation control system

XN-2DO-24VDC-2A-P EATON Touch Panel

MH2-340-57MPI-1-1E Human Machine Interaction

XV-112-DB-70TWRC-70 Eaton human-machine touch screen

MC2-442-57CQB-1-21 Eaton human-machine touch screen

MC2-440-10TVB-1-10 EATON HMI Human Machine Interface

MH2-340-57BAS-1-1D Eaton human-machine touch screen

XV-440-10TVB-1-1U Eaton human-machine touch screen

XVS-430-10MPI-1-10 EATON HMI Human Machine Interface

XVS-460-57MPI-1-1A Eaton human-machine touch screen

XN-KO/11 Capacitive touch screen and resistive touch screen

XVM-410-65TVB-1-11 EATON HMI Human Machine Interface

XN-KO/1 Capacitive touch screen and resistive touch screen

XV-252-57CNN-1-1KVAR08 EATON HMI Human Machine Interface

XT-BCB-TP Intelligent operation control system

XV-102-B2-35TQR-10 EATON HMI Human Machine Interface

XV-230-57MPN-1-10-PLC-SET EATON HMI Human Machine Interface

XN-S6S-SBCSBC Eaton human-machine touch screen

MC2-442-57CQB-1-1C Eaton human-machine touch screen

MC2-440-12TSB-1-1K EATON HMI Human Machine Interface

XVC-601-GTI-12-V1-000 Eaton human-machine touch screen