Description

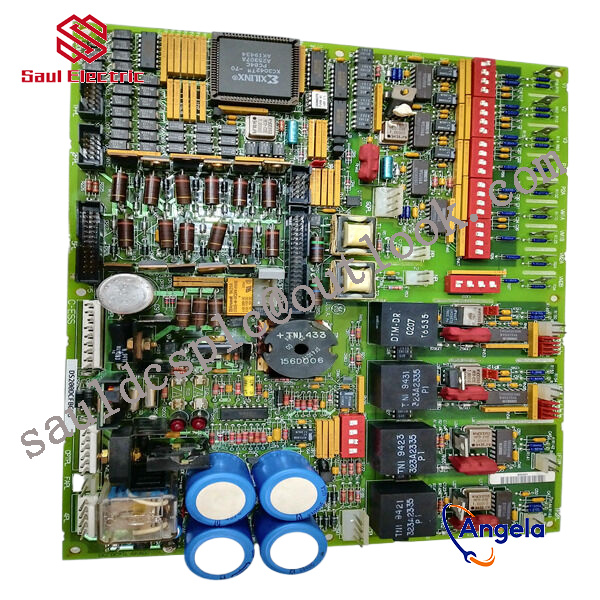

IS215VCMIH2C Product Introduction

The specific application scope of the product

will depend on the needs of system integration and industrial application, but generally speaking, this type of embedded controller module can be applied to the following categories:

manufacturing processes, etc.

monitoring and control system.

of the controller module, as well as the specific needs of the customer.

designed to manage gas or steam turbines.

It has a CIMPLICITY graphical interface and an HMI with software suitable for running heavy-duty turbines.

be installed at the bottom of the cabinet. For a small setup that is easy to serve a triple redundant system, up to three components can be installed side by side.

he board can operate within a temperature range of 0 to 65 degrees Celsius without the need for a fan for cooling. NFPA Class 1. This board can be used for two applications.

Design and implementation of variable frequency transmission system based on ABB hardware architectureintroductionWith the increasing development of transmission technology and the increasing demand for actual use, variable frequency transmission systems have been widely used.As a Fortune 500 company in the world, ABB is a leader in the fields of power and automation technology and has strong capabilities in control systems, high-voltage, medium-voltage and low-voltage frequency conversion technology and transmission technology. Therefore, this article mainly relies on ABB”s control, frequency conversion and transmission technology, and uses related hardware products to design and implement the frequency conversion transmission system.To truly design and implement a usable variable frequency drive system, the entire system must be fully equipped, conveniently operable and compatible with a wide range of needs, so that it can be used without changing the control method and operation. According to the actual control needs, that is, combining frequency converters with different performances and variable frequency motors with different speeds or torques to quickly build and realize a variety of control requirements.1 System design purpose and compositionThe design purpose of this system is to control ABB inverters through local and remote control methods and complete 4 independent channels of closed-loop speed control to drive different test objects to rotate.The entire control system consists of the following four main components: remote control computer, panel industrial computer (touch screen), PLC and speed-regulating frequency converter. The system design block diagram is shown in Figure 1.In order to ensure the accuracy of motor speed control, an encoder module is added. The PLC can obtain the feedback of the rotary encoder in the frequency converter through the ProfibusDP protocol. The speed control is performed through the frequency converter for internal PID closed-loop control.2 System hardware implementation2.1 Control some hardwareThe control part of the hardware mainly refers to the sum of hardware that supports operators to use the equipment directly or indirectly and complete the functions of the equipment. Its main hardware includes computer control terminal, touch screen control terminal, PLC control unit, other auxiliary circuits and measurement and control components.2.2 Transmission hardwareThe transmission hardware mainly refers to the total number of equipment that can relatively independently perform a complete transmission function. Its main hardware includes frequency converters, variable frequency motors (configured with rotary encoders as needed) and other auxiliary circuits. Among them, the selection of motors and frequency converters should be based on the principle of selecting the motor first and then selecting the frequency converter. details as follows:First, according to the tangential speed at which the object under test is to complete rotation, select the motor speed according to the following formula:Secondly, choose based on several other important basic parameters of the motor, such as system hardness, torque, weight, etc. This system uses ABB”s variable frequency motor.Finally, select an appropriate frequency converter based on the motor power. In addition, the actual situation of the object being tested must also be taken into consideration, such as whether the rotating load belongs to the heavy-load usage of the frequency converter, etc.3Software systemSystem software includes three major categories in total, namely computer control software, touch screen software and PLC software. Among them, the PLC software, as the underlying software, is responsible for the interaction with the computer control software and touch screen software on the upper side, and the interaction with the frequency converter on the lower side. Therefore, from the architecture of the entire software system, it can be defined as a host and slave computer structure.3.1 System development platformThe software system has two control methods: remote and local. The development platforms for the three major categories of software are Windows operating system, LabVIEW[4] integrated development environment, CodesysV2.3, and CP400.3.2 System software architectureThe software of the entire system is divided into three types, namely remote control software, PLC control software and local control software. Among them, the remote control software runs under the Windows operating system and is developed under the LabVIEW integrated development environment; the PLC control software is developed under the CodesysV2.3 programming environment; the local control software runs on the touch screen computer and is developed under the CP400 environment. The relationship between the three software is shown in Figure 2.

IS200VSVOH1B From General Electric in the United States

IS230TVBAH4A High performance processor module GE

IS210AEBIH1BAA GE power control board

IS200VRTDH1DAC From General Electric in the United States

IS200TSVCH2ADC Gas turbine system Mark VI

DS200LRPAG1AAA Gas turbine system Mark VI

DS215TCQAG1BZZ01A I/O excitation redundant module GE

DS200DCFBG1BLC I/O excitation redundant module GE

IS210BPPCH1AC Processor/Controller Mark VI System

IS210AEBIH1BED From General Electric in the United States

IS200ISBEH2ABB GE power control board

IS200VPWRH1AF GE power control board

IS200ERRRH1A Gas turbine system Mark VI

IS200VTCCH1CBB High performance processor module GE

IS200TBACIH1B Gas turbine system Mark VI

IS200VTCCH1CBB GE power control board

IS200RCSBG1BAA From General Electric in the United States

IS200ICIAH1ABB From General Electric in the United States

IS200TREGH1B GE power control board

IS215UCVEH2A Processor/Controller Mark VI System

IS200ISBBG2AAB Processor/Controller Mark VI System

IS200TREGH1BDB Gas turbine system Mark VI

IS220PVIBH1A I/O excitation redundant module GE

DS200CTBAG1ACC From General Electric in the United States

IS200BPIAG1AEB From General Electric in the United States

IS200ERRBG1A High performance processor module GE

IS200VSVOH1BDC I/O excitation redundant module GE

DS200TCCAG1BAA GE power control board

DS200TCTGG1AFF GE power control board

IS200EXHSG3AEC High performance processor module GE

IS200TPROS1CBB High performance processor module GE

IS200EXAMG1A Gas turbine system Mark VI

IS220PDOAH1B I/O excitation redundant module GE

IS200WETBH1BAA GE power control board

IS200VCMIH1BCC Processor/Controller Mark VI System

DS200UCPBG6AFB Processor/Controller Mark VI System

IS200TRLYH2C I/O excitation redundant module GE

DS200TCQAG1BEC Processor/Controller Mark VI System

IS215SUCVEH2AE Gas turbine system Mark VI

IS230TBAIH2C High performance processor module GE

IS200ECTBG1ADE I/O excitation redundant module GE

IS200JPDPG1A GE power control board

IS200TBCIH1BBC High performance processor module GE

IS200TREGH1BDC I/O excitation redundant module GE

IS215UCVEM09A Gas turbine system Mark VI

IS200BICIH1ADB Processor/Controller Mark VI System

IS215ACLEH1A High performance processor module GE

IS200SAMBH1A Gas turbine system Mark VI

IS200TREGH1B I/O excitation redundant module GE

IS220PTCCHIA Processor/Controller Mark VI System

IS215PCMIH1AC Gas turbine system Mark VI

IS220PTURH1A GE power control board