Description

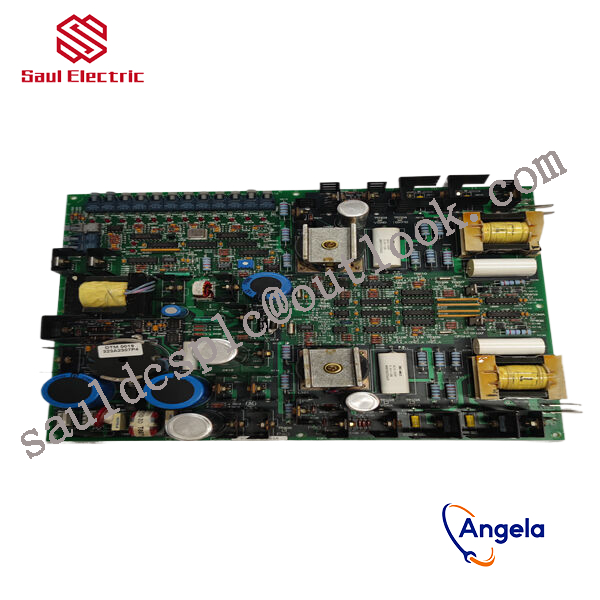

DS200SDCCG4AFD Product Introduction

The specific application scope of the product

will depend on the needs of system integration and industrial application, but generally speaking, this type of embedded controller module can be applied to the following categories:

manufacturing processes, etc.

monitoring and control system.

of the controller module, as well as the specific needs of the customer.

designed to manage gas or steam turbines.

It has a CIMPLICITY graphical interface and an HMI with software suitable for running heavy-duty turbines.

be installed at the bottom of the cabinet. For a small setup that is easy to serve a triple redundant system, up to three components can be installed side by side.

he board can operate within a temperature range of 0 to 65 degrees Celsius without the need for a fan for cooling. NFPA Class 1. This board can be used for two applications.

3 Case Studies on Reducing Scrap RatesAny product assembled or produced in a factory goes through a series of quality tests to determine whether it needs to be scrapped. High scrap rates are caused by the opportunity cost of not delivering products to customers in a timely manner, wasted personnel time, wasted non-reusable parts, and equipment overhead expenses. Reducing scrap rates is one of the main issues manufacturers need to address. Ways to reduce scrap include identifying the root causes of low product quality.3.1 Data processingRoot cause analysis begins by integrating all available data on the production line. Assembly lines, workstations, and machines make up the industrial production unit and can be considered equivalent to IoT sensor networks. During the manufacturing process, information about process status, machine status, tools and components is constantly transferred and stored. The volume, scale, and frequency of factory production considered in this case study necessitated the use of a big data tool stack similar to the one shown in Figure 2 for streaming, storing, preprocessing, and connecting data. This data pipeline helps build machine learning models on batch historical data and streaming real-time data. While batch data analytics helps identify issues in the manufacturing process, streaming data analytics gives factory engineers regular access to the latest issues and their root causes. Use Kafka (https://kafka.apache.org) and Spark streaming (http://spark.apache.org/streaming) to transmit real-time data from different data sources; use Hadoo (http://hadoop.apache.org ) and HBase (https://hbase.apache.org) to store data efficiently; use Spark (http://spark.apache.org) and MapReduce framework to analyze data. The two main reasons to use these tools are their availability as open source products, and their large and active developer network through which these tools are constantly updated.

IS215VCMIH2B I/O excitation redundant module GE

DS200SDCIG1AEB Processor/Controller Mark VI System

IS230TNTRH1C High performance processor module GE

IS220PPDAH1A Processor/Controller Mark VI System

IS220PRTDH1B GE power control board

IS400JPDHG1ABB From General Electric in the United States

IS200TPROS1CBB Processor/Controller Mark VI System

IS210AEDBH3A From General Electric in the United States

IS200TRLYH1B Processor/Controller Mark VI System

DS200VPBLG1AEE High performance processor module GE

IS200DSPXH2CAA From General Electric in the United States

IS200ERSCG2A High performance processor module GE

IS220PAOCH1A I/O excitation redundant module GE

DS200TCQAG1BHF From General Electric in the United States

IS220YSILS1BB From General Electric in the United States

IS200DTAIH1ACC Gas turbine system Mark VI

DS3820PSCB1C1B I/O excitation redundant module GE

IS420UCSBH1A Processor/Controller Mark VI System

IS220PAICH1B I/O excitation redundant module GE

IS210DPWAG1AA From General Electric in the United States

DS200DMCBG1A Processor/Controller Mark VI System

IS220PDIOH1A I/O excitation redundant module GE

IS220PSCAH1A High performance processor module GE

IS200GDDDG1A From General Electric in the United States

IS220YDIAS1A Gas turbine system Mark VI

IS200SRLYH2AAA GE power control board

IS215UCVEM06A Gas turbine system Mark VI

IS420UCSBH1A I/O excitation redundant module GE

IS210TRPGH1B Processor/Controller Mark VI System

DS200TCCBG8BED Processor/Controller Mark VI System

IS215ACLEH1B From General Electric in the United States

IS200TRESH1A From General Electric in the United States

IS215UCCAM03 Processor/Controller Mark VI System

DS200SLCCG3ACC Processor/Controller Mark VI System

DS200TCQCG1BHF Processor/Controller Mark VI System

IS200TSVCH1AJE High performance processor module GE

IS200ISBDG1AAA GE power control board

IS200VAICH1D High performance processor module GE

IS220PPDAH1A GE power control board

IS220PAOCH1BD GE power control board

IS230SAISH1A High performance processor module GE

IS215ACLEH1B Gas turbine system Mark VI

IS200VATFG1AAA I/O excitation redundant module GE

IS220PRTDH1A From General Electric in the United States

IS200TTURH1B High performance processor module GE

IS200TGENH1A Processor/Controller Mark VI System

IS220PAICHIA I/O excitation redundant module GE

IS200EISBH1AAA High performance processor module GE

IS2020RKPSG3A Processor/Controller Mark VI System

IS200VAICH1DAB GE power control board

IS420ESWBH3A Gas turbine system Mark VI

DS200PLIBG1ACA GE power control board

IS400TCASH1AEC I/O excitation redundant module GE

IS200TNH1A Processor/Controller Mark VI System

IS220PDIOH1B I/O excitation redundant module GE

IS210DTTCH1AA GE power control board

DS200CPCAG1A Processor/Controller Mark VI System

DS200SDCCG5AHD I/O excitation redundant module GE

IS215VCMIH1B Gas turbine system Mark VI