Description

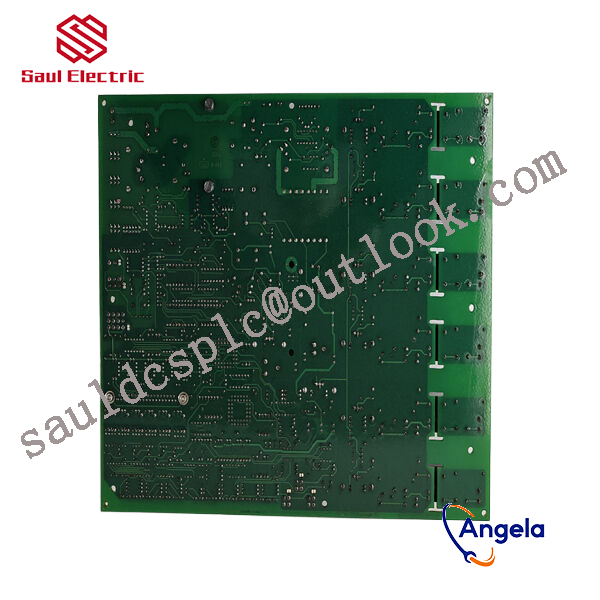

DS200PCCAG5ACB Product Introduction

The specific application scope of the product

will depend on the needs of system integration and industrial application, but generally speaking, this type of embedded controller module can be applied to the following categories:

manufacturing processes, etc.

monitoring and control system.

of the controller module, as well as the specific needs of the customer.

designed to manage gas or steam turbines.

It has a CIMPLICITY graphical interface and an HMI with software suitable for running heavy-duty turbines.

be installed at the bottom of the cabinet. For a small setup that is easy to serve a triple redundant system, up to three components can be installed side by side.

he board can operate within a temperature range of 0 to 65 degrees Celsius without the need for a fan for cooling. NFPA Class 1. This board can be used for two applications.

China, which is transforming from a manufacturing power to a manufacturing power, is also a major consumer of industrial robots.In the past year, local governments represented by Shanghai, Chongqing, Shandong and other places have focused on high-end manufacturing.In the first half of this year, Shanghai”s manufacturing investment increased by 22% year-on-year, a double-digit growth that has not been seen in recent years. Among them, the robot industry is quite representative.At the just-concluded CIIE, robotics giants gained a lot. At present, among the four major robot families, the Swiss company ABB, the German company KUKA, and the Japanese companies Yaskawa and FANUC have all increased their investment in the Chinese robot market.After sorting out the development paths of the four major robotics giants in China in the past year, as well as the local government’s focus on high-end manufacturing and preferential industrial policies. Analysts from the 21st Century Economic Research Institute believe that local governments should provide manufacturing companies with a relaxed production environment and business environment through tax cuts, streamlining administration and delegating powers.At the same time, local policies should not unilaterally pursue automation and intelligence through subsidies for “buy, buy, buy”, but should encourage technological innovation in a guided manner. Represented by the robot industry, while cooperating with the four major families, domestic industrial robots should also increase innovation and enhance their core competitiveness and market share.The Chinese Bureau of the Four Major Robot FamiliesChina, which is transforming from a major manufacturing country to a powerful manufacturing country, is also a major consumer of industrial robots. This market has always been optimistic about the outside world.Officials from the Ministry of Industry and Information Technology previously stated that China”s industrial robot sales reached 141,000 units in 2017, becoming the world”s largest application market for five consecutive years. By 2020, China”s robot demand will account for 40% of global demand.Over the past year, robotics giants have accelerated their efforts to seize the Chinese market and have also won huge orders in China. The four major robot families account for more than 70% of the market share of China”s robot industry and are close to monopolizing high-end fields such as robot manufacturing and welding.In 2018, ABB”s Robot Application Center in Chongqing officially opened, focusing on meeting the rapidly growing market demand for industrial robots in the western region”s automotive, 3C product manufacturing, equipment manufacturing and consumer goods manufacturing fields. At the end of October, ABB announced an investment of US$150 million to build the world”s largest and most advanced robot super factory in Kangqiao, Shanghai, to expand production capacity and better meet surging customer demand. In mid-November, ABB Xiamen Industrial Center in Xiamen Torch (Xiang”an) Industrial Zone was officially opened. With an investment of US$300 million, it is one of ABB”s largest and most advanced manufacturing bases in the world. In mid-November, ABB and the Guangdong Provincial Government signed a strategic cooperation framework agreement. The two parties will further deepen strategic cooperation in the fields of power, industry, transportation and infrastructure.In terms of production capacity, ABB”s newly built super factory in Kangqiao, Shanghai can produce 100,000 industrial robots, which will complete the production of a quarter of the world”s industrial robots. More than 90% of ABB”s robots sold in the Chinese market are developed and manufactured in China, achieving local development, local production and local transportation.The CEO of German KUKA stated at the CIIE that KUKA is positioned as China”s largest robot company. China is one of the most important markets in the future and it wants to gain the largest market share. In 2016, KUKA and Chongqing Changan Industrial Co., Ltd. established a robotics joint venture in Chongqing. In March 2018, KUKA announced the establishment of a new robot factory in Shunde, Guangdong. Six years later, the company”s production capacity in China will be increased to 100,000 units.

IS200ERBPG1A High performance processor module GE

IS200ESYSH3A Gas turbine system Mark VI

IS215ISBBH1A I/O excitation redundant module GE

DS200DSFBG1ACB Gas turbine system Mark VI

IS200DTAIH1ACC Processor/Controller Mark VI System

IS200VPWRH1A GE power control board

IS200JPDPG1A Processor/Controller Mark VI System

DS200DCFBG1BNC GE power control board

IS200XDIAG1A High performance processor module GE

IS210AEPSG2BBA Gas turbine system Mark VI

DS200FGPAG1A Processor/Controller Mark VI System

DS200PCCAG6ACB High performance processor module GE

IS200TRLYH1B Gas turbine system Mark VI

IS215VCMIH2CA Processor/Controller Mark VI System

IS215VCMIH1B GE power control board

IS200VCMIH1BCC High performance processor module GE

IS200TTURH1CED Gas turbine system Mark VI

DS200SDCCG4A I/O excitation redundant module GE

IS420YAICS1B Processor/Controller Mark VI System

IS200JPDSG1ACBGE I/O excitation redundant module GE

IS420ESWAH1A Gas turbine system Mark VI

IS200ICBDH1BAA Processor/Controller Mark VI System

IS200AVGBG1A Gas turbine system Mark VI

IS215ACLEH1BC GE power control board

IS230SNAIH4A GE power control board

IS200VTCCH1CBD Gas turbine system Mark VI

IS200TBAIH1CDC GE power control board

IS200ADIIH1A From General Electric in the United States

IS420PVIBH1B From General Electric in the United States

IS200ACLEH1BCB Gas turbine system Mark VI

IS200TREGH1B Processor/Controller Mark VI System

IS420UCPAH1A Gas turbine system Mark VI

IS200CPFPG1A High performance processor module GE

DS200FGPAG1AHD High performance processor module GE

DS200SLCCG1ABB I/O excitation redundant module GE

IS220PSVOH1A Processor/Controller Mark VI System

IS215GBIAH1A GE power control board

IS200TRPSH1A GE power control board

DS200TCTGG1AFF From General Electric in the United States

IS200EPSMG2A High performance processor module GE

IS200SAMBH1A Processor/Controller Mark VI System

IS420UCSCS2A GE power control board

IS200DTURH1ACC Processor/Controller Mark VI System

IS200DSFCG1A High performance processor module GE

IS200ERIOH1AAA GE power control board

IS200GGXDG1AA Gas turbine system Mark VI

IS200AEPAH1BCA I/O excitation redundant module GE

IS200RAPAG1BAA GE power control board

IS220YSILS1BB High performance processor module GE

IS220PTURH1A High performance processor module GE

DS200DCFBG1BLC High performance processor module GE

DS200TCPDG1B GE power control board

DS200ADMAH1A GE power control board