Description

I. Brand Background

II. Product Features

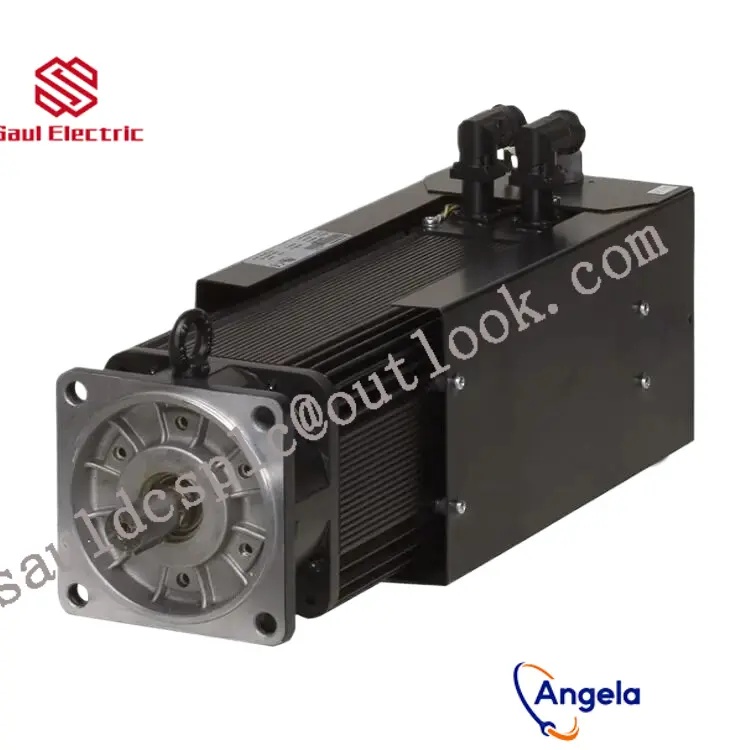

- High Performance: The 8MSA3M.R0-A8 servo motor offers high precision, rapid response, and excellent stability, meeting the demands of various complex automation applications.

- Integrated Safety Technology: B&R”s servo motors incorporate advanced safety technologies, such as the openSAFETY standard,

- ensuring the safety of operators while supporting machine functionality. This safety technology adapts to changing configurations and operates reliably worldwide.

- Easy Management: With intelligent safety response capabilities, the 8MSA3M.R0-A8 servo motor simplifies machine option management without compromising safety levels.

- This helps reduce downtime risks and enhance production efficiency.

- Networked Collaboration: B&R”s integrated, networked safety technology enables coordinated responses to safety events across the entire production line.

- The use of safety standards like openSAFETY ensures secure communication and interoperability between devices from different manufacturers.

- Powerful Software Support: B&R”s Automation Studio software development platform provides robust support for configuring, commissioning,

- and maintaining servo motors. Users can easily accomplish various automation tasks through this platform.

III. Application Areas

IV. Product Advantages

- Genuine Products: The 8MSA3M.R0-A8 servo motor is manufactured in Austria, ensuring product quality and performance.

- Professional Services: B&R has a professional technical support and after-sales service team capable of providing timely and efficient technical support and solutions to users.

- Customization Options: B&R offers customized servo motor solutions to meet the specific needs of different users.

The best motor is one that meets the application requirements. However, when both servo motors and stepper motors meet the basic requirements

for positioning applications, it is important to have a deeper understanding of these two technologies to make informed decisions.

In this blog post, we will summarize the differences between servo motor systems and stepper motor systems.

Let”s start with a quick comparison of these two motor technologies.

stepper motor

servo motor

Advantages and benefits

Good low-speed torque

No adjustments, no hunting

Compact motor size

High cost-effective high-speed torque

Available peak torque

continuous work

fully functional

Disadvantages and weaknesses

Low high-speed torque

Limited work cycle

No peak torque

Usually running in open-loop mode requires adjustment

Only applicable for feedback

hunting

cost

Although both servo motors and stepper motors use permanent magnets in the rotor and require drive circuits to operate,

their designs have fundamental differences, resulting in performance differences.

Motor Design

The stepper motor can be commanded to move to a certain position, stop, and then hold, while the servo motor needs

to “find” the target position through encoder feedback. The first major difference you will notice is that servo motors require an increase in the length of the encoder.

The second main difference is polar numbers. The magnetic pole discussed here is the “magnetic pole”, which can be defined

as the north or south magnetic pole on the rotor. These magnetic poles provide specific stable points, and the magnetic flux from the stator will interact with the rotor.

To understand the difference in pole numbers between stepper motors and servo motors, we need to have a deeper understanding

of each motor design. The left figure shows the structure of a stepper motor, and the right figure shows a cross-sectional view of the rotor and stator.

stepper motor

The stepper motor design uses axially magnetized rare earth permanent magnets sandwiched between two toothed rotor cups.

By magnetizing the permanent magnet axially, the teeth of the two rotor cups are made into magnetic poles of opposite polarity. A rotor cup

can have 50 or 100 teeth, with two rotor cups tilted at half the pitch. The teeth of the two rotors are shown in blue and red in the upper right image (if viewed from the shaft side). For stepper motors, each tooth on the two rotor cups becomes a pole.