Description

I. Brand Background

II. Product Features

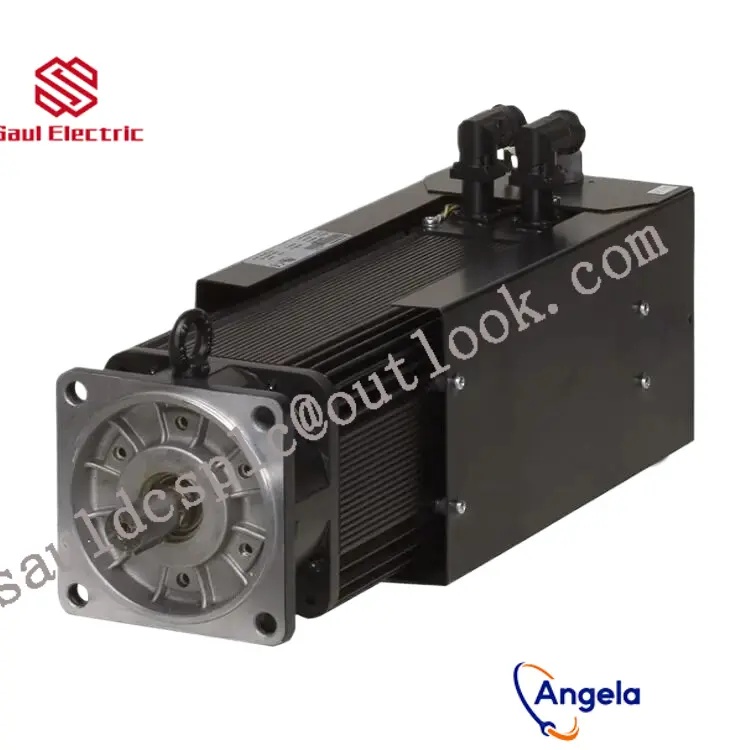

- High Performance: The 8LSA45.E3030C104-0 servo motor offers high precision, rapid response, and excellent stability, meeting the demands of various complex automation applications.

- Integrated Safety Technology: B&R”s servo motors incorporate advanced safety technologies, such as the openSAFETY standard,

- ensuring the safety of operators while supporting machine functionality. This safety technology adapts to changing configurations and operates reliably worldwide.

- Easy Management: With intelligent safety response capabilities, the 8LSA45.E3030C104-0 servo motor simplifies machine option management without compromising safety levels.

- This helps reduce downtime risks and enhance production efficiency.

- Networked Collaboration: B&R”s integrated, networked safety technology enables coordinated responses to safety events across the entire production line.

- The use of safety standards like openSAFETY ensures secure communication and interoperability between devices from different manufacturers.

- Powerful Software Support: B&R”s Automation Studio software development platform provides robust support for configuring, commissioning,

- and maintaining servo motors. Users can easily accomplish various automation tasks through this platform.

III. Application Areas

IV. Product Advantages

- Genuine Products: The 8LSA45.E3030C104-0 servo motor is manufactured in Austria, ensuring product quality and performance.

- Professional Services: B&R has a professional technical support and after-sales service team capable of providing timely and efficient technical support and solutions to users.

- Customization Options: B&R offers customized servo motor solutions to meet the specific needs of different users.

Principle of Variable Frequency Motor

Variable frequency motor refers to a motor that operates continuously at 100% rated load within the range of 10% to 100% rated speed under standard environmental conditions,

and the temperature rise does not exceed the allowable value of the motor calibration.

With the rapid development of power electronics technology and new semiconductor devices, AC speed regulation technology has been continuously improved and enhanced.

Gradually improved frequency converters have been widely used in AC motors due to their good output waveforms and excellent performance price ratios. For example,

large electric motors and medium to small roller conveyor motors used for steel rolling in steel mills, traction motors for railways and urban rail transit, elevator motors,

lifting motors for container lifting equipment, motors for water pumps and fans, compressors, and motors for household appliances have all successively used AC variable frequency

speed regulation motors and achieved good results. The use of AC variable frequency speed regulation motors has significant advantages over DC speed regulation motors:

(1) Speed regulation is easy and energy-saving.

(2) The AC motor has a simple structure, small size, low inertia, low cost, easy maintenance, and durability.

(3) It can expand capacity and achieve high-speed and high-voltage operation.

(4) It can achieve soft start and fast braking.

(5) No sparks, explosion-proof, and strong environmental adaptability.

Main characteristics of variable frequency motor

The frequency conversion dedicated motor has the following characteristics:

B-class temperature rise design, F-class insulation manufacturing. The use of polymer insulation materials and vacuum pressure coating manufacturing processes,

as well as the adoption of special insulation structures, greatly improves the insulation withstand voltage and mechanical strength of electrical windings, making them

capable of withstanding high-speed motor operation and resisting high-frequency current impact and voltage damage to insulation in frequency converters.

High balance quality, vibration level of R (reduced vibration level), high machining accuracy of mechanical components, and the use of dedicated high-precision bearings, which can operate at high speed.

The forced ventilation cooling system adopts imported axial flow fans with ultra quiet, high lifespan, and strong wind power. Ensure effective heat dissipation of the

motor at any speed, enabling long-term operation at high or low speeds.

The YP series motor designed by AMCAD software has a wider speed range and higher design quality compared to traditional variable frequency motors.

Through special magnetic field design, it further suppresses high-order harmonic magnetic fields to meet the design indicators of broadband, energy saving, and low noise

. It has a wide range of constant torque and power speed regulation

characteristics, with smooth speed regulation and no torque pulsation.

It has good parameter matching with various frequency converters, and with vector control, it can achieve zero speed full torque, low-frequency large torque and high-precision

speed control, position control and fast dynamic response control. The YP series frequency conversion dedicated motor can be equipped with brakes and encoders, which can

achieve precise parking and high-precision speed control through speed closed-loop control.

Adopting “reducer+frequency conversion dedicated motor+encoder+frequency converter” to achieve precise control of ultra-low speed stepless speed regulation.

The YP series frequency conversion dedicated motor has good universality, and its installation dimensions comply with IEC standards, making it interchangeable with general standard motors.

Variable frequency motor wiring

R. S and T are inputs, U, V, and W are outputs! If the motor needs to switch from frequency conversion to power frequency operation, then the U, V,

and W output from the frequency conversion must be in phase sequence with the U, V, and W input from the power frequency!

Principle of Variable Frequency Motor – Variable Frequency Motor Wiring

The return circuit of the motor frequency converter is mainly as follows: the R, S, and T ports are the input ports for power supply, and the output ports of the

frequency converter are U, V, and W, which are respectively connected to the motor. When we are accustomed to the forward rotation of the frequency converter of the motor, we first connect the

intermediate relay and the motor together to the control input common terminal. At this time, the forward rotation starts, and the normally open contact of the intermediate relay is energized because it is closed.

At this time, the motor rotates forward. If the current is lost, the motor will stop.

In the entire wiring process of the motor frequency converter, it is inevitable to set the parameters of the frequency converter.

We need to set the frequency and operation mode of the frequency converter. In addition to these basic settings, we also need to set the maximum frequency and basic frequency of the

current. The rated voltage, maximum output voltage, and related time can all be changed together. Finally, there are some functions such as data protection, LCE monitoring, and start-up frequency

holding time that can be further set according to the type of frequency converter from different manufacturers.