Description

I. Brand Background

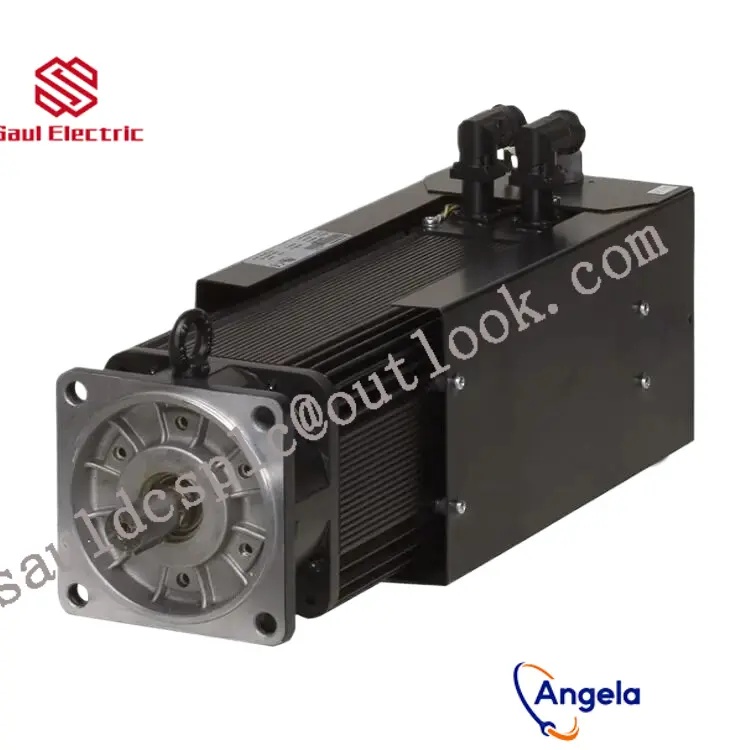

II. Product Features

- High Performance: The 80MPD5.600S014-01 servo motor offers high precision, rapid response, and excellent stability, meeting the demands of various complex automation applications.

- Integrated Safety Technology: B&R”s servo motors incorporate advanced safety technologies, such as the openSAFETY standard,

- ensuring the safety of operators while supporting machine functionality. This safety technology adapts to changing configurations and operates reliably worldwide.

- Easy Management: With intelligent safety response capabilities, the 80MPD5.600S014-01 servo motor simplifies machine option management without compromising safety levels.

- This helps reduce downtime risks and enhance production efficiency.

- Networked Collaboration: B&R”s integrated, networked safety technology enables coordinated responses to safety events across the entire production line.

- The use of safety standards like openSAFETY ensures secure communication and interoperability between devices from different manufacturers.

- Powerful Software Support: B&R”s Automation Studio software development platform provides robust support for configuring, commissioning,

- and maintaining servo motors. Users can easily accomplish various automation tasks through this platform.

III. Application Areas

IV. Product Advantages

- Genuine Products: The 80MPD5.600S014-01 servo motor is manufactured in Austria, ensuring product quality and performance.

- Professional Services: B&R has a professional technical support and after-sales service team capable of providing timely and efficient technical support and solutions to users.

- Customization Options: B&R offers customized servo motor solutions to meet the specific needs of different users.

Flexible conveying for efficient production

SuperTrak is a new generation flexible conveyor system developed by B&R, consisting of guide rails, trays, and two ABB robots IRB 910SC and IRB120. SuperTrak,

based on maglev control technology, solves the bottleneck of factory conveyor systems and achieves customized, efficient, and flexible manufacturing for any batch, even batch size of “1”.

The traditional conveyor system uses a conveyor belt or a mechanical divider to transport all products, while SuperTrak uses separate trays to independently transport each product or part,

enhancing conveying flexibility. Each tray can be freely set according to needs and combined into a production process sequence, which is transmitted at independent speed, acceleration

, spacing, and direction without buffering, improving conveying efficiency. SuperTrak”s guide rails adopt a closed-loop design, and the circumference can be customized according to

customer needs, with a maximum length of up to 50 meters. The tray can be placed at any position on the guide rail,

avoiding waste of conveying time. At the same time, due to the use of electromagnetic technology, the tray does not directly contact the track, reducing the

vibration during tray transportation and improving transportation stability.

Each tray on SuperTrak is equipped with two to three permanent magnets, and the coils on the guide rails and the permanent magnets on the tray can generate suction

and thrust to move the tray on the guide rails. The number of permanent magnets varies, resulting in different suction and thrust forces, which can meet different industrial manufacturing needs.

Due to the fact that the tray is fixed to the guide rail by suction rather than mechanical devices, it only takes a few seconds to install or remove the tray, and it is labor-saving,

easy to quickly change the product and maintain the system. At the same time, the normal production time is greatly improved, and in many scenarios,

the production efficiency is 5-10 times higher than traditional conveying.

Seamless integration with ABB robots

The ABB robots IRB 910SC and IRB 120 are located at both ends of the SuperTrak guide rail loop, seamlessly integrated with SuperTrak. With just one controller,

SuperTrak can be connected to the robot in real-time, achieving a high degree of automation in production. SuperTrak has an accuracy of up to+/-0.01mm, and the robot and tray work together to

quickly and accurately locate products and complete complex actions.

ABB”s IRB 910SC SCARA four axis robot has a small size, high precision, and excellent path control, making it suitable for applications that require fast, repetitive,

and coherent motion, such as small part assembly, loading and unloading, etc. IRB 120 is an ABB agile, compact, and lightweight six axis small robot with excellent control accuracy and path accuracy,

making it an ideal choice for material handling and assembly applications. In addition, SuperTrak can be integrated with more models of ABB robots according to the production needs of different customers,

helping customers improve production efficiency and save manpower. Before the conference, let”s take a look at the laboratory video first!

The SuperTrak conveying system is widely used in any manufacturing field that requires high flexibility, precision, and efficiency. It can help users achieve fast, flexible, and accurate parameter configuration

and production collaboration, shorten process adjustment and design cycles, and meet the market demand for mass customization and personalized customization. In the Chinese market, hundreds

of meters of SuperTrak have been widely used in various industries, helping multiple companies in the fields of 3C electronics, lithium batteries,

food and beverage, medicine, etc. to improve cost efficiency and market competitiveness.