Description

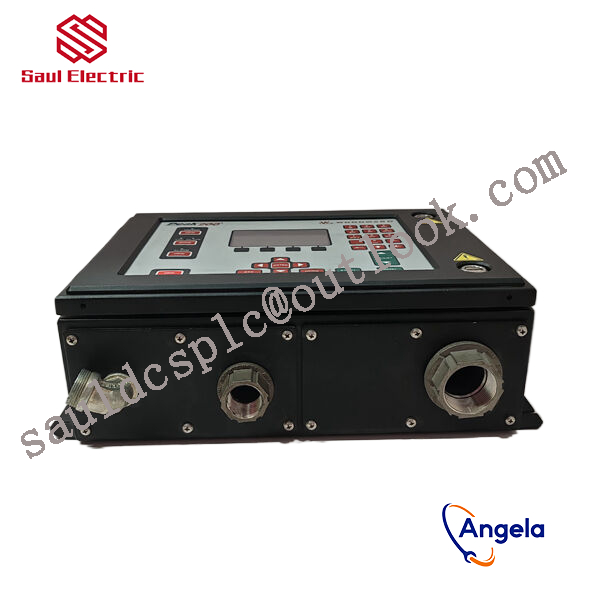

9907-1200 WOODWARD generator set speed control board

9907-1200 Product Introduction

Non differential regulation is mainly used for constant speed control and is suitable for single machine operation or multiple prime movers working together in an isolated power grid. Differential regulation provides more control flexibility.

further enhancing its performance and application range.

rich additional functions, and high-precision output signals. Whether it is in the fields of generator sets, compressors, pump stations, or ships and locomotives, it can effectively ensure the stable operation of equipment within the set range.

power measurement level 1, editable screen, multi interface toolkit connection, etc. All details can be found in Woodward easyYgen manual 37582A

The rated operating temperature range of this model is -20 to 70 ° C; the rated temperature range of the LT model is -40 to 70 ° C, suitable for outdoor use.

9907-1200 is equipped with a monitor (not available on the 3100 model) and is designed for front panel installation.

The built-in HMI has a color LCD and soft keys (now with dedicated buttons) for direct control of the 9907-1200 device. Multi level password protection can prevent unauthorized changes.

The generator set has four operating modes and the option to configure a manual circuit breaker control device.

How to use 9907-1200?

What is 9907-1200 used for?

9907-1200 Customs Code

When German Chancellor Mucker inserted an index finger into the mechanical tongs at the Hannover Messe and insisted on personally testing the intelligence of the robot “Corn”, almost all the audience present held their breath and sweated in their hearts. But his pliers immediately stayed in place, and everyone breathed a sigh of relief.Since the establishment of ABB China Research Institute in 2005, ABB China R&D personnel have developed the world”s fastest and most accurate six-axis robot – the “Dragon” IRB 120, and officially launched the world”s first true robot to the market at the Hannover Industrial Fair in Germany. YuMi (“Corn”), a dual-arm industrial robot that realizes human-machine collaboration.On the occasion of the tenth anniversary of the establishment of ABB China Research Institute, Mr. Claes Rytoft, the group”s global chief technology officer, was interviewed by reporters on ABB”s robotics business development and other issues.Reporter: Is the development of the robot “Corn” targeted at the application needs of specific industries?Claes Rytoft: Before talking about “corn”, let”s first look at other robots that have been used in industry before. They are basically industrial arms that do some complex repetitive work. But these robot arms are not safe. They must be placed in a cage and separated from people at a distance because they are not safe enough.So let”s look back at “Corn”, he can collaborate with others, he can stand next to you and participate in the work together. In the process of your human-machine collaboration, if you accidentally touch it with your arm, it will immediately slow down or even stop. This collaborative robot is an innovation in the entire field of robotics.Let me tell you a tidbit. At the Hannover Industrial Fair in Germany last week, ABB”s robot “Corn” became the focus, and it was almost one of the most attractive booths at the expo. At that time, German Chancellor Mucker insisted on personally testing the safety and intelligence of “Corn”, so he inserted his index finger into the mechanical tongs on “Corn””s arm. At that time, almost all the spectators present held their breath and were sweating in their hearts, fearing that something would go wrong and Mucker would be injured. But as soon as Mukeer put his fingers in, his pliers immediately stopped in place, and everyone breathed a sigh of relief.This example also shows that “Corn” is a true human-machine collaborative robot, and the users it targets are users who need human-machine collaborative work.”Corn” can be used in many assembly and manufacturing industries. In terms of human-machine collaboration, there is no compromise in the accuracy of its operation, and it can accurately reach an accuracy of 0.02 mm, which is equivalent to the smallest gap that can be felt by the human hand. To put it figuratively, you can use “corn” to “thread the needle”.Reporter: What is the development direction of ABB Robotics in China? What is the driving force for development?Claes Rytoft: ABB”s robot business first started in the automotive industry. In the era of mass production in the 1950s and 1960s, robots were used to perform complex and dangerous operations, such as spraying and welding.Take welding as an example. To ensure that welding meets standards, it must be operated by very skilled technical workers, and robots can also meet standards after being programmed. This is why the first robot was born at ABB”s Swedish research institute and was quickly promoted to worldwide.There is always room for development in this industry, and saturation is relative. China has now become a production base for electronic consumer products, and most of the production factories still rely on manual labor. Therefore, when ABB established a robot R&D and manufacturing base in Shanghai in 2005, it began to study which manufacturing industries robots should serve, and finally believed that it could replace Labor in these factories is also a new development direction. This depends more on the Chinese team.In 2009, Dr. Gu Chunyuan, chairman and president of ABB (China) Co., Ltd., led a local team to successfully develop the IRB 120 robot, which is specifically designed for small parts assembly in the automotive industry.As for the driving force of development, it is cost. In 2005, Dr. Gu Chunyuan went to a labor-intensive equipment company in China for research. At that time, he imagined that if the robot designed by ABB could complete all the operations of human hands on this production line, it would be able to relieve these young people from these heavy and intensive tasks. Freed from extremely boring and highly repetitive labor to do other things. This is why ABB Robotics has determined such a development direction in China.

5466-348 WOODWARD generator set speed control board

1751-147D WOODWARD Speed Sensor Full Series

5464-727 Controller debugger generator WOODWARD

FA-1763-1 WOODWARD Speed Sensor Full Series

5501-470 From Woodward, USA

8580-085 Controller debugger generator WOODWARD

5463-583 Generator Parts Speed Controller 2301A Speed

986LCD-M/mITX Generator Parts Speed Controller 2301A Speed

5464-414 WOODWARD generator set speed control board

5464-555 From Woodward, USA

5463-582 Controller debugger generator WOODWARD

5415-856 Controller debugger generator WOODWARD

5461-770 WOODWARD 2301A Speed Control Controller

2301E 8273-1011 WOODWARD 2301A Speed Control Controller

5501-365 Generator Parts Speed Controller 2301A Speed

9771-210 From Woodward, USA

5439-800 Generator Parts Speed Controller 2301A Speed

5437-844 Controller debugger generator WOODWARD

1843-325 WOODWARD 2301A Speed Control Controller

5463-473 C Controller debugger generator WOODWARD

5463-579 WOODWARD Speed Sensor Full Series

5439-927 From Woodward, USA

9905-970 WOODWARD generator set speed control board

5464-439 WOODWARD 2301A Speed Control Controller

8250-501 Controller debugger generator WOODWARD

5464-645 WOODWARD generator set speed control board

5501-432 Controller debugger generator WOODWARD

9905-973 WOODWARD generator set speed control board

8237-2601 WOODWARD generator set speed control board

5461-622 Generator Parts Speed Controller 2301A Speed

9905-020 WOODWARD 2301A Speed Control Controller

9900-427 WOODWARD Speed Sensor Full Series

8915-877 From Woodward, USA

5437-1067A WOODWARD generator set speed control board

B8516-038 From Woodward, USA

5463-870 WOODWARD 2301A Speed Control Controller

9905-990 Generator Parts Speed Controller 2301A Speed

8256-021 Generator Parts Speed Controller 2301A Speed

8272-582 Controller debugger generator WOODWARD

8440-1706 WOODWARD generator set speed control board

5463-779 WOODWARD 2301A Speed Control Controller

9907-147 Controller debugger generator WOODWARD

5462-966 Generator Parts Speed Controller 2301A Speed

9907-1200 WOODWARD 2301A Speed Control Controller

9907-019 Controller debugger generator WOODWARD

5501-470 Controller debugger generator WOODWARD

8273-140 WOODWARD 2301A Speed Control Controller

5416-352 WOODWARD generator set speed control board

5462-584 WOODWARD 2301A Speed Control Controller

8406-113 WOODWARD Speed Sensor Full Series

5439-861 From Woodward, USA

9907-166 WOODWARD generator set speed control board

8516-076 WOODWARD Speed Sensor Full Series

8915-712 Controller debugger generator WOODWARD

5463-796 WOODWARD generator set speed control board