Description

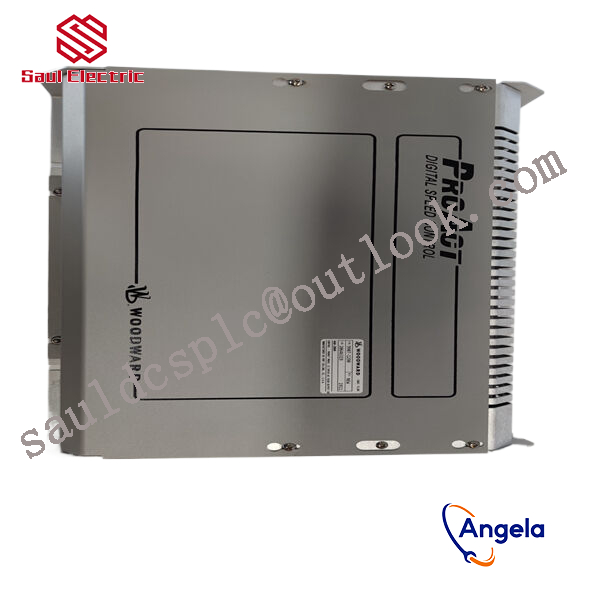

9907-1183 Generator Parts Speed Controller 2301A Speed

Non differential regulation is mainly used for constant speed control and is suitable for single machine operation or multiple prime movers working together in an isolated power grid. Differential regulation provides more control flexibility.

further enhancing its performance and application range.

rich additional functions, and high-precision output signals. Whether it is in the fields of generator sets, compressors, pump stations, or ships and locomotives, it can effectively ensure the stable operation of equipment within the set range.

power measurement level 1, editable screen, multi interface toolkit connection, etc. All details can be found in Woodward easyYgen manual 37582A

The rated operating temperature range of this model is -20 to 70 ° C; the rated temperature range of the LT model is -40 to 70 ° C, suitable for outdoor use.

9907-1183 is equipped with a monitor (not available on the 3100 model) and is designed for front panel installation.

The built-in HMI has a color LCD and soft keys (now with dedicated buttons) for direct control of the 9907-1183 device. Multi level password protection can prevent unauthorized changes.

The generator set has four operating modes and the option to configure a manual circuit breaker control device.

How to use 9907-1183?

What is 9907-1183 used for?

9907-1183 Customs Code

3.3 Design of computer control softwareThis type of control software runs on the computer and is mainly used for remote operation. It has multiple functions such as parameter setting, control operation, data collection and storage, status detection and alarm, etc. Its interface is shown in Figure 3.The system shown in Figure 3 contains four independent control channels, and the software can manage and configure the test plan based on parameter information. That is: for each test plan, you can configure different test plans and set different test parameters through the “Configuration” operation. You can also create new plans, save and modify plans, open existing plans, and delete plans.The software also sets up quick operations, which can quickly start and stop work according to the channel configuration, and can detect the working status of each channel in real time.3.4 Design of touch screen softwareThe touch screen software is mainly used for local control and runs in the touch screen controller. While the computer control software has similar functions, it also has the setting function of local control priority or remote control priority. The default is remote control priority. The login interface and test operation interface are shown in Figure 4 and Figure 5 respectively.3.5 Design of PLC softwareAs the core of this control system, PLC is mainly responsible for the following aspects:Responsible for sending corresponding control parameters and instructions to the frequency converter, and at the same time obtaining the status of the transmission system through the ProfibusDP bus protocol.Communicates with the touch screen through serial communication, responds to local control instructions, and feeds back system status to the touch screen as a slave computer for local control. Programming between the touch screen and PLC is performed by directly accessing the PLC variable address.It communicates with the remote control computer through the OPC[5] communication method based on the external network, responds to the remote control instructions, and feeds back the system status to the remote control computer as the remote control slave. Programming between the remote control program and the PLC is performed by accessing the PLC variable name.Process the emergency signal and control the inverter to slow down and unload according to the default parameters.Figure 4 Login interfaceFigure 5 Test interface3.6 Frequency converter settingsIn general, the inverter will be equipped with an optional operation panel. Before using the local or remote control program to operate the inverter, you must first perform the basic settings of the inverter, as follows:Switch the control mode to local control and set the inverter address according to the inverter user manual.Set the inverter for remote control and select the communication mode.Set the frequency converter to use an encoder, and connect the motor for self-test matching operation.Set the speed control mode of the inverter, such as speed control or torque control.After completing the basic parameter settings, switch to the remote control state and wait for remote control.4 ConclusionThis system implements a universal belt-turning mechanism that utilizes frequency conversion control technology. You can use the local touch screen to control the inverter to control the motor rotation and obtain corresponding feedback, or you can use remote control to control the inverter to achieve the same control effect as the local touch screen, even in view of the computer function The richness allows you to obtain more system information and set more control states. In addition to local touch screen control and remote control, the overall structure of this system can also be split into the most basic transmission structure to complete the control, that is, the motor is controlled directly through the control panel of the frequency converter to achieve the most basic and direct control. Therefore, this system can be used as a basic framework structure to meet all similar control requirements, and obtain different levels of usage requirements through different levels of hardware configuration, which has universal reference significance.

8234-167O Generator Parts Speed Controller 2301A Speed

5464-596 Generator Parts Speed Controller 2301A Speed

5462-762 WOODWARD generator set speed control board

5464-768 WOODWARD generator set speed control board

9905-002N WOODWARD 2301A Speed Control Controller

5501-471 Controller debugger generator WOODWARD

5464-828 From Woodward, USA

5461-643 Controller debugger generator WOODWARD

5453-279 Controller debugger generator WOODWARD

8272-684 Generator Parts Speed Controller 2301A Speed

8440-2150 WOODWARD generator set speed control board

SPM-D11 8440-1706B WOODWARD generator set speed control board

5464-018 From Woodward, USA

8271-147 Controller debugger generator WOODWARD

5439-076 Controller debugger generator WOODWARD

5466-268 Controller debugger generator WOODWARD

8236-144D WOODWARD 2301A Speed Control Controller

5464-836 Controller debugger generator WOODWARD

9907-175 Controller debugger generator WOODWARD

8575-377 WOODWARD generator set speed control board

5464-716A WOODWARD 2301A Speed Control Controller

5439-861 Generator Parts Speed Controller 2301A Speed

5501-003 Controller debugger generator WOODWARD

8237-2597 From Woodward, USA

5461-088 Generator Parts Speed Controller 2301A Speed

5461-002 WOODWARD Speed Sensor Full Series

5460-841 From Woodward, USA

8440-1884 WOODWARD generator set speed control board

1680-631 WOODWARD 2301A Speed Control Controller

9905-971 Generator Parts Speed Controller 2301A Speed

5501-471 Generator Parts Speed Controller 2301A Speed

8580-085 From Woodward, USA

1886-313 WOODWARD generator set speed control board

A8523-210 WOODWARD generator set speed control board

9905-990 WOODWARD 2301A Speed Control Controller

5437-418 Generator Parts Speed Controller 2301A Speed

5462-268 WOODWARD Speed Sensor Full Series

5463-124 WOODWARD Speed Sensor Full Series