Description

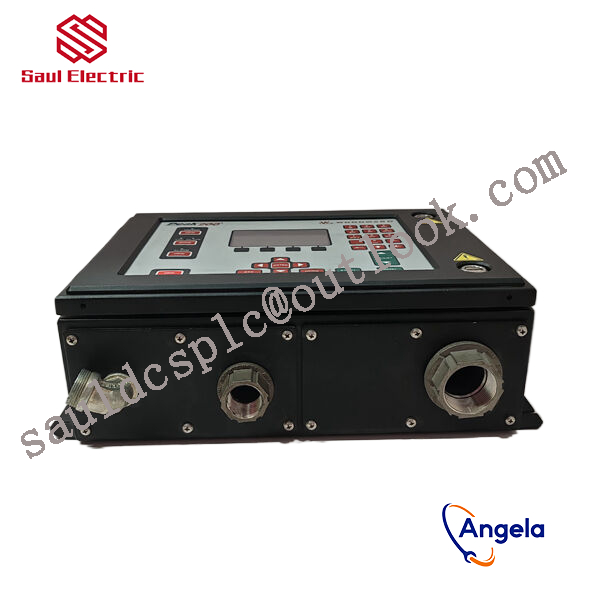

8440-2145 WOODWARD generator set speed control board

Non differential regulation is mainly used for constant speed control and is suitable for single machine operation or multiple prime movers working together in an isolated power grid. Differential regulation provides more control flexibility.

further enhancing its performance and application range.

rich additional functions, and high-precision output signals. Whether it is in the fields of generator sets, compressors, pump stations, or ships and locomotives, it can effectively ensure the stable operation of equipment within the set range.

power measurement level 1, editable screen, multi interface toolkit connection, etc. All details can be found in Woodward easyYgen manual 37582A

The rated operating temperature range of this model is -20 to 70 ° C; the rated temperature range of the LT model is -40 to 70 ° C, suitable for outdoor use.

8440-2145 is equipped with a monitor (not available on the 3100 model) and is designed for front panel installation.

The built-in HMI has a color LCD and soft keys (now with dedicated buttons) for direct control of the 8440-2145 device. Multi level password protection can prevent unauthorized changes.

The generator set has four operating modes and the option to configure a manual circuit breaker control device.

How to use 8440-2145?

What is 8440-2145 used for?

8440-2145 Customs Code

ABB Ability™ solutions are based on data integration, analysis and decision-making to create maximum value for customersABB has been deeply involved in the field of industrial digitalization for many years, and has installed a large number of connected equipment and systems to help customers create a lot of value. Taking a step further, the ABB Ability™ digital solution launched in October 2016 laid a new foundation for ABB to establish its leadership position in the industrial Internet of Things market and helped thousands of companies around the world achieve safety and efficiency. Data integration and analysis to make optimized decisions enhances the innovation and competitiveness of enterprises. Its applications cover equipment monitoring, asset health, predictive maintenance, energy management, emission monitoring, collaborative operations, remote support, virtual debugging and other fields. .Take the construction of power supply and distribution systems that need to be guaranteed in scenarios such as smart hospitals, smart parks, data centers, and rail transit as an example. The equipment is affected by the aging mechanism during operation and shows a deterioration trend. Traditional solutions can only rely on inspections and regular maintenance. In order to delay the deterioration process, hidden dangers cannot be discovered in time. According to ARC survey results in the United States, preventive maintenance of regular maintenance and inspection can only have an effect on 18% of components or assets, and 82% of assets or components will show random failure modes, causing unplanned power outages.The targeted health management mechanism of ABB Ability™ digital solutions is based on the aging mechanism of equipment to achieve self-perception of status, quantify health scores, proactively predict failure risks, and guide customers to optimize operating conditions through the “intelligent brain” to improve operation and maintenance. efficiency, reducing losses from unplanned power outages, realizing the perfect combination of digital electrical equipment and the Internet of Things, and transforming smart management from passive prevention to active prediction.On the other hand, due to limited professional talent resources and lack of comprehensive analysis and overall tuning capabilities, the problem of low energy usage efficiency is low. The mobile power distribution housekeeper provided by ABB Ability™ digital solution will comprehensively integrate equipment health and operating status. The expert brain platform optimizes the operation strategy of the power distribution system. At the same time, through data storage, calculation, and analysis, it realizes the intelligent release of local status quantities, electrical quantities, fault information, alarm information, and equipment information. It can be monitored locally at the monitoring workstation or through mobile Remote monitoring of equipment enables mobile operation and maintenance.ABB Ability™ digital solutions help realize intelligent operation, maintenance and intelligent management of power supply and distribution systemsIn summary, this is the value of ABB Ability™ digital solutions – integrating ABB”s deep industry expertise and rich experience in connectivity, providing insight into the connotation of data, providing professional analysis suggestions and optimizing the planning and controllability of actual operations. nature, providing insights for safer, smarter, and more sustainable operations, allowing customers to focus on their own advantages and seize more market opportunities in the fourth industrial revolution and energy revolution.In addition, from the infrastructure level, the full range of ABB Ability™ digital solution equipment has achieved interconnection based on the latest IoT technology, and digital twins, edge and cloud IoT and data analysis platforms have been successfully deployed.Fully launched in the Chinese market, the digital industry cooperation and win-win ecosystem is increasingly matureIn order to further help Chinese customers tap the market potential of industrial digital transformation and provide smarter, one-stop digital services, ABB Ability™ digital solutions have been continuously iterated, innovated and upgraded since they were first launched in the Chinese market in 2017. Currently, they are provided Its more than 220 industry solutions have been widely verified by the market and have accumulated rich experience in China”s implementation, building a win-win digital industry cooperation ecosystem.For example, ABB has joined hands with Feihe Dairy, a benchmark company for high-quality dairy products in the domestic dairy industry, to provide UniSafe medium-voltage switchgear, MDmax ST low-voltage switchgear, PQF active dynamic filters and ABB Ability™ EAM energy efficiency and asset health management cloud platform for multiple factories ( (formerly ABB EDCS), continuously and efficiently provide high-quality and reliable power guarantee to meet the operation and safety needs of the production line to the greatest extent, and jointly create a greener, low-carbon, energy-saving and environmentally friendly food factory.

3462-757 Controller debugger generator WOODWARD

9905-969 WOODWARD Speed Sensor Full Series

9905-973 Controller debugger generator WOODWARD

8440-1849 From Woodward, USA

5437-092 WOODWARD Speed Sensor Full Series

5464-538 Generator Parts Speed Controller 2301A Speed

8272-447 WOODWARD Speed Sensor Full Series

5501-469 WOODWARD generator set speed control board

5466-329 Controller debugger generator WOODWARD

5461-944 WOODWARD generator set speed control board

5462-532 WOODWARD 2301A Speed Control Controller

8516-038 WOODWARD Speed Sensor Full Series

5464-332 Controller debugger generator WOODWARD

5461-653 WOODWARD 2301A Speed Control Controller

8923-811 WOODWARD generator set speed control board

5464-836 WOODWARD generator set speed control board

5462-520 WOODWARD generator set speed control board

8236-144 WOODWARD Speed Sensor Full Series

5415-737 WOODWARD Speed Sensor Full Series

5463-750 WOODWARD 2301A Speed Control Controller

1886-313 WOODWARD Speed Sensor Full Series

8516-039 WOODWARD Speed Sensor Full Series

5500-018 WOODWARD generator set speed control board

8273-126 WOODWARD 2301A Speed Control Controller

8440-2150 From Woodward, USA

5437-860 Generator Parts Speed Controller 2301A Speed

A9904-060 Generator Parts Speed Controller 2301A Speed

5463-482 From Woodward, USA

5463-408 WOODWARD Speed Sensor Full Series

5463-034 From Woodward, USA

5464-542 WOODWARD 2301A Speed Control Controller

9907-1198 Generator Parts Speed Controller 2301A Speed

9907-1183 WOODWARD Speed Sensor Full Series

5501-466 WOODWARD generator set speed control board