Description

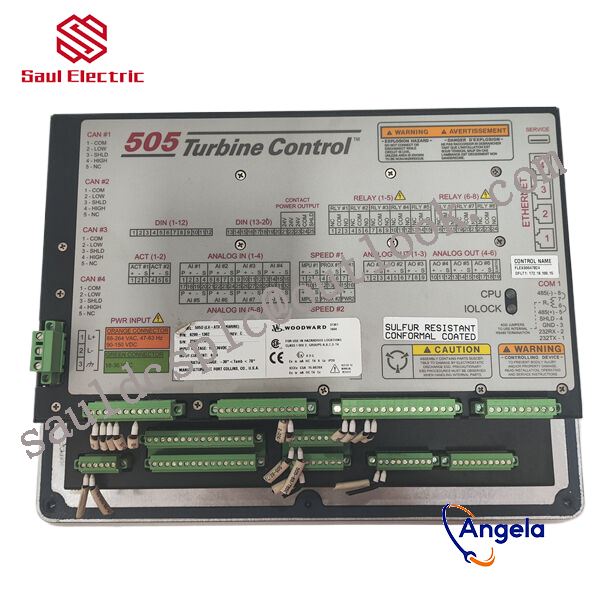

8256-016 Controller debugger generator WOODWARD

Non differential regulation is mainly used for constant speed control and is suitable for single machine operation or multiple prime movers working together in an isolated power grid. Differential regulation provides more control flexibility.

further enhancing its performance and application range.

rich additional functions, and high-precision output signals. Whether it is in the fields of generator sets, compressors, pump stations, or ships and locomotives, it can effectively ensure the stable operation of equipment within the set range.

power measurement level 1, editable screen, multi interface toolkit connection, etc. All details can be found in Woodward easyYgen manual 37582A

The rated operating temperature range of this model is -20 to 70 ° C; the rated temperature range of the LT model is -40 to 70 ° C, suitable for outdoor use.

8256-016 is equipped with a monitor (not available on the 3100 model) and is designed for front panel installation.

The built-in HMI has a color LCD and soft keys (now with dedicated buttons) for direct control of the 8256-016 device. Multi level password protection can prevent unauthorized changes.

The generator set has four operating modes and the option to configure a manual circuit breaker control device.

How to use 8256-016?

What is 8256-016 used for?

8256-016 Customs Code

Globally, more than 200,000 ABB robots are working in industrial fields. China is one of the major future growth areas. To capitalize on these growth opportunities, ABB Robotics has joined forces with companies with global engineering capabilities that serve as R&D bases. Festo is one of its global partners.ABB robots entered the Chinese market in 1994; in 2005, ABB established a robot research and development center in Shanghai. ABB is currently the only multinational company that has built a full industry chain of industrial robot R&D, production, sales, engineering, and services in China. It serves the automotive, consumer products, electronics and other industries and is used in die-casting and forging, metal and plastic processing, and solar energy. areas such as technology and electronic components and machining. ABB”s global robot production base in Kangqiao, Shanghai, has produced a total of 20,000 robots, making it the industrial robot production base with the highest cumulative output in China.Advantages of automationMore and more customers in the above industrial fields want to focus on their core competencies. Therefore, they recognize the advantages of automation as it can alleviate heavy task loads, increase productivity and thus achieve greater efficiency, simplicity and reliability.ABB focuses on further developing its core competencies in robot control technology and assembling complete robot systems, and Festo , as ABB”s high-quality professional supplier, has always provided ABB with comprehensive support for specific functions. Festo “s long-term partnership with ABB goes back decades.Outstanding Supplier AwardThe close customer/supplier relationship between ABB Robotics and Festo has become a highlight – not long ago, Festo won the “ABB Robotics China Outstanding Supplier Award 2013” and became the best among about 1,500 suppliers. one. Festo won this award not only for the high quality of its automation products, but also especially for its know-how in the field of engineering solutions and its comprehensive support for ABB”s value-added chain.ABB”s relationship with Festo begins with cooperation at the local level between a number of ABB”s international subsidiaries and Festo. Since 2005, Festo Germany and Festo China have signed formal regional cooperation agreements with ABB China. One of the successful cases of cooperation at the product and solution level is the Purge Air Kit – mainly used on robots in the spraying production lines of automobile factories. The Purge Air Kit is a ready-to-install maintenance module with accessories such as sensors and fittings. It creates an overpressure inside the robot arm, thus preventing dust particles from entering and damaging its function.

5463-432 From Woodward, USA

8280-107 From Woodward, USA

9905-537 From Woodward, USA

A9904-060 Controller debugger generator WOODWARD

5466-042 WOODWARD generator set speed control board

5462-522 Controller debugger generator WOODWARD

8256-021 WOODWARD Speed Sensor Full Series

9904-173 WOODWARD 2301A Speed Control Controller

5453-203 Controller debugger generator WOODWARD

5415-737 Controller debugger generator WOODWARD

8516-039 Generator Parts Speed Controller 2301A Speed

9906-707 WOODWARD 2301A Speed Control Controller

9907-490 Controller debugger generator WOODWARD

8290-194 WOODWARD Speed Sensor Full Series

8444-1019F WOODWARD 2301A Speed Control Controller

5437-283 From Woodward, USA

5466-032 WOODWARD generator set speed control board

5464-536 Controller debugger generator WOODWARD

5417-417 Generator Parts Speed Controller 2301A Speed

5464-205 WOODWARD 2301A Speed Control Controller

8272-385 From Woodward, USA

8440-1715 SPM-D11 WOODWARD Speed Sensor Full Series

5464-768 WOODWARD 2301A Speed Control Controller

5464-828 Controller debugger generator WOODWARD

8230-896 WOODWARD Speed Sensor Full Series

5466-061 WOODWARD generator set speed control board

5463-729 Generator Parts Speed Controller 2301A Speed