Description

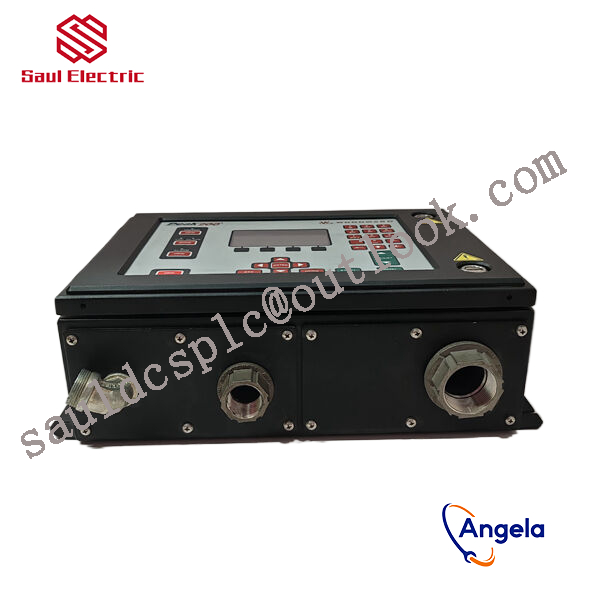

8230-898 WOODWARD Speed Sensor Full Series

8230-898 Product Introduction

Non differential regulation is mainly used for constant speed control and is suitable for single machine operation or multiple prime movers working together in an isolated power grid. Differential regulation provides more control flexibility.

further enhancing its performance and application range.

rich additional functions, and high-precision output signals. Whether it is in the fields of generator sets, compressors, pump stations, or ships and locomotives, it can effectively ensure the stable operation of equipment within the set range.

power measurement level 1, editable screen, multi interface toolkit connection, etc. All details can be found in Woodward easyYgen manual 37582A

The rated operating temperature range of this model is -20 to 70 ° C; the rated temperature range of the LT model is -40 to 70 ° C, suitable for outdoor use.

8230-898 is equipped with a monitor (not available on the 3100 model) and is designed for front panel installation.

The built-in HMI has a color LCD and soft keys (now with dedicated buttons) for direct control of the 8230-898 device. Multi level password protection can prevent unauthorized changes.

The generator set has four operating modes and the option to configure a manual circuit breaker control device.

How to use 8230-898?

What is 8230-898 used for?

8230-898 Customs Code

The series of products displayed by SIASUN this time include the seven-axis collaborative robot SCR series, the six-axis collaborative robot GCR series, and the composite robot HCR series and other full range of platform-based multi-functional collaborative robot products. The application display covers education, logistics, traditional manufacturing, and services. and many other fields. Among them, GCR14 shows the advantage of an ultra-long arm span of 1400mm. As the robot with the longest arm span in the collaborative robot family, it can meet the application of some special scenarios. In applications such as avoiding obstacles and some large-radius working ranges, GCR14 can flexibly adapt to .In order to lower the threshold and cost of use, while improving the integration efficiency of robots and terminal vision, SIASUN combines independently developed collaborative robot products with DUCO mind, an intelligent application controller that integrates vision and force sensors, algorithms and application data packages for various industries. The combination expands the application scenarios of robots + AI in industrial production.3. Midea Group made a grand appearance, and four major sectors including KUKA Robotics merged for the first timeAs a well-known brand of home appliances in China, Midea Group has an exhibition hall of 1,000 square meters at the Industrial Expo. It shows off its muscles in its super-scale debut, which is cool and luxurious! This time, the group will bring KUKA Robots, Meiyun Smart Digital, central air-conditioning, and installation equipment to the exhibition hall. The four major sectors of Dezhilian will be unveiled together. Many highlight products such as robots, industrial Internet, air-conditioning energy-saving systems, and smart logistics will fully demonstrate the latest achievements of Midea Group”s “two comprehensives (comprehensive digitalization, comprehensive intelligence)” strategic transformation. The results will create a beautiful world of “perfect technology and perfect life”!In the KUKA robot segment, a newly launched robot has the characteristics of “more powerful, faster and more flexible”, with a maximum payload of 4 kg and an arm span of 600 mm. The compact body combines outstanding performance with a larger workspace for demanding and space-constrained workflows. The robot is equipped with the new KR C5 micro control cabinet, which can control and handle various tasks more effectively.In addition, KR 4 AGILUS can be installed in any position and can still demonstrate its superior performance when operating at operating temperatures of 0°-55°. Faster beats and superior motion trajectory accuracy can help customers improve production efficiency and achieve goals faster. This robot focuses on “powerful, fast and efficient”. Whether in the assembly of small parts, handling or material testing – the two new compact KR scara robots combined with the new KR C5 micro control cabinet demonstrate higher work efficiency.Data show that on January 6, 2017, the delivery work of Midea Group’s acquisition of KUKA Robot Company was completed, and the transaction consideration of 22.9 billion yuan was fully paid. This acquisition is of great significance for Midea to improve its own industrial chain and realize the strategic transformation of the enterprise. This year”s China Industry Fair Robot Exhibition will see Midea and KUKA robots join forces for the first time to jointly demonstrate the upgrade and breakthrough of the manufacturing industry. It is full of expectations!4. Human-machine collaboration, FANUC’s strength appears at the Industrial ExpoFANUC, also one of the four major families of robots, demonstrated the organic integration of robot automation and Internet of Things technology with the theme of “human-machine collaboration, intelligent future”. Through human-machine collaboration, flexible manufacturing, and individuality Customized production to provide users with a full range of intelligent manufacturing solutions.At the Industrial Expo, FANUC exhibited the CRX-10iA new generation collaborative robot for the first time in China. CRX-10iA has three major characteristics: high security, high reliability, and convenient use. As a small collaborative robot, the CRX-10iA has a maximum load of 10kg and a reach radius of 1249mm. Its long-arm model CRX-10iA/L has a reach radius of 1418mm. CRX provides users with accurate, flexible and safe human-machine collaboration solutions for application needs such as the handling and assembly of small components.In addition, FANUC provides a full range of cutting-edge technologies and advanced applications in the field of automation to assist users in production. There are more than 10 sets of industry automation solutions on site for automobiles, auto parts, 3C electronics, warehousing and logistics, plastics, metal processing and other industries. Intelligent manufacturing empowerment.5. ASD Qianjiang Robot appeared with a variety of products

5463-790 Generator Parts Speed Controller 2301A Speed

5416-339 From Woodward, USA

8200-203 WOODWARD Speed Sensor Full Series

5441-409 WOODWARD Speed Sensor Full Series

EGB-10P Controller debugger generator WOODWARD

5464-660 From Woodward, USA

8271-674 Controller debugger generator WOODWARD

5461-290 WOODWARD Speed Sensor Full Series

5462-521 Generator Parts Speed Controller 2301A Speed

9907-838 From Woodward, USA

9907-018 Controller debugger generator WOODWARD

8250-818 WOODWARD 2301A Speed Control Controller

5453-278 WOODWARD generator set speed control board

9905-204 Controller debugger generator WOODWARD

9907-018 WOODWARD Speed Sensor Full Series

5461-083 Controller debugger generator WOODWARD

5501-376 Generator Parts Speed Controller 2301A Speed

8915-986 From Woodward, USA

5460-837 WOODWARD Speed Sensor Full Series

5462-520 WOODWARD Speed Sensor Full Series

5437-054 Controller debugger generator WOODWARD

9905-144 WOODWARD Speed Sensor Full Series

5437-080 WOODWARD 2301A Speed Control Controller

8440-2047 WOODWARD Speed Sensor Full Series

8440-2165 Generator Parts Speed Controller 2301A Speed

5466-033 Generator Parts Speed Controller 2301A Speed

8915-103 WOODWARD generator set speed control board

5464-332 From Woodward, USA

8440-2082 EG3200XT WOODWARD Speed Sensor Full Series

8580-086 Generator Parts Speed Controller 2301A Speed

5464-332 WOODWARD 2301A Speed Control Controller

5462-472 WOODWARD 2301A Speed Control Controller

9907-018 From Woodward, USA

5441-695 WOODWARD Speed Sensor Full Series

3462-757 WOODWARD generator set speed control board

8915-775 Controller debugger generator WOODWARD

5466-258 WOODWARD generator set speed control board

SPM-D11 8440-1703 Generator Parts Speed Controller 2301A Speed