Description

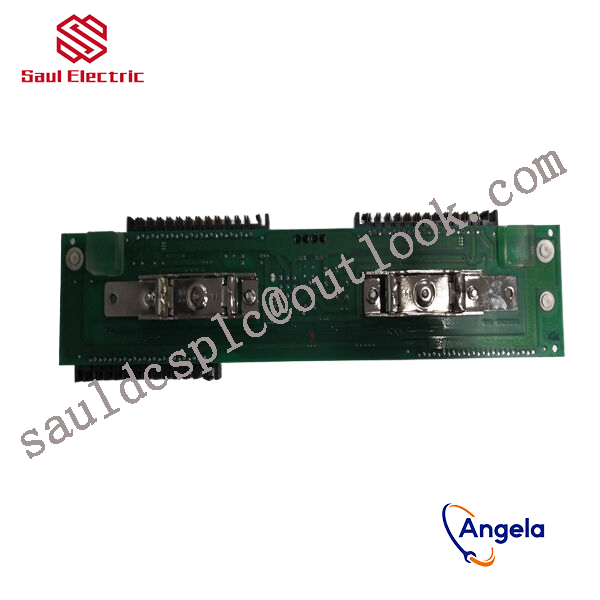

5X00419G01 Relay output logic module Emerson

thereby controlling external devices or circuits.

A stepper driver is an actuator that converts electrical pulses into angular displacement. When the stepper driver receives a pulse signal, it drives the stepper motor to rotate a fixed angle (called the “step angle”) in the set direction, and its rotation runs step by step at a fixed angle. By controlling the number of pulses, the angular displacement can be controlled to achieve accurate positioning; At the same time, the speed and acceleration of the motor can be controlled by controlling the pulse frequency, thus achieving the purpose of speed regulation and positioning. Widely used in high-resolution large and medium-sized CNC equipment such as carving machines, crystal grinding machines, medium-sized CNC machine tools, EEG embroidery machines, packaging machinery, fountains, dispensing machines, cutting and feeding systems, etc.

It is a power amplifier that can operate a stepper motor. It can convert the pulse signal sent by the controller into the angular displacement of the stepper motor. The motor speed is proportional to the pulse frequency, so controlling the pulse frequency can accurately adjust the speed, and controlling the number of pulses can accurately locate.

Principle of stepper driver

1. Constant current drive

Stepper Driver Principle Stepper Motor Driver Selection

The basic idea of constant current control is to control the conduction time of MOSFETs in the main circuit, that is, to adjust the pulse width of MOSFET trigger signals, in order to achieve the goal of controlling the output driving voltage and thus controlling the motor winding current.

2. Unipolar drive

Unipolar and bipolar are the two most commonly used driving architectures for stepper motors. The unipolar driving circuit uses four transistors to drive the two phases of the stepper motor. The motor structure, as shown in Figure 1, includes two sets of coils with a center tap. The entire motor has six wires connected to the outside world. This type of motor is sometimes referred to as a four phase motor, but this term can be confusing and incorrect because it actually only has two phases. The precise description would be a dual phase six wire stepper motor. Although the six wire stepper motor is also known as a unipolar stepper motor, it can actually use both unipolar and bipolar driving circuits simultaneously.

responsible for processing signals from on-site sensors or driving actuator actions. For example, they may need to cooperate with devices such

as BANNER travel switch T30UIPB to receive their transmitted position signals; Or by controlling components such as Burkert solenoid valve 00131421, the on/off of fluid media can be precisely managed.

these modules integrate more complex logic processing capabilities. The core task of a pressure switch is to detect whether the pressure

has reached a preset threshold and output a switch signal. Its function is highly specific and fixed. And modules 5X00419G01 and 1

C31219G01 have the ability to comprehensively judge multiple such switch signals and transmitter signals (such as transmitter 1066-P-HT-60),

and output complex control instructions according to internal logic.