Description

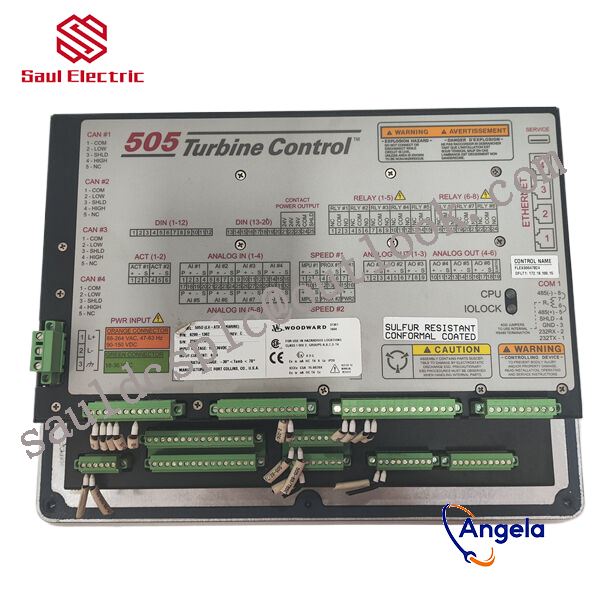

5461-880 From Woodward, USA

Non differential regulation is mainly used for constant speed control and is suitable for single machine operation or multiple prime movers working together in an isolated power grid. Differential regulation provides more control flexibility.

further enhancing its performance and application range.

rich additional functions, and high-precision output signals. Whether it is in the fields of generator sets, compressors, pump stations, or ships and locomotives, it can effectively ensure the stable operation of equipment within the set range.

power measurement level 1, editable screen, multi interface toolkit connection, etc. All details can be found in Woodward easyYgen manual 37582A

The rated operating temperature range of this model is -20 to 70 ° C; the rated temperature range of the LT model is -40 to 70 ° C, suitable for outdoor use.

5461-880 is equipped with a monitor (not available on the 3100 model) and is designed for front panel installation.

The built-in HMI has a color LCD and soft keys (now with dedicated buttons) for direct control of the 5461-880 device. Multi level password protection can prevent unauthorized changes.

The generator set has four operating modes and the option to configure a manual circuit breaker control device.

How to use 5461-880?

What is 5461-880 used for?

5461-880 Customs Code

ABB and Kawasaki launch cross-border cooperation to promote collaborative robot automation development As the global aging trend intensifies, the service robot market is gradually heating up. It is reported that ABB and Kawasaki announced that they will work together to promote cooperation in collaborative robot automation. Collaborative robots will address labor shortages and aging issues for society and the world. Recently, ABB and Kawasaki Heavy Industries, the world”s two largest suppliers of industrial automation robots, have reached a partnership. The two will share knowledge and promote the development of collaborative robot projects, especially in the design of dual-arm robots. Collaborative automation enables people and machines to work together, with each person contributing their unique strengths, providing knowledge, insight, and improvisation, while the robots provide repetitive tasks and tireless stamina. This is a cross-border cooperation. ABB is the largest robot supplier in Europe, and Kawasaki Asia is also a giant in the industry. The scale and speed of the development of robots today are unimaginable. In addition to collaborative automation technology, the cooperation between the two also has a new way of working together and creating industrial safety collaboration. Collaborative robots can help society and the world cope with labor shortages and an aging population, especially those with arms that can interact with humans. There is great potential to expand collaborative applications and processes, and people and technology to co-create solutions, and ABB and Kawasaki have joined forces to bring a more human touch to drive advanced collaborative automation. ABB has sold more than 300,000 robot solutions in different industries and is recognized as a leader in collaborative automation through yumi”s dual-arm robot. It launched the world”s first true collaborative robot and has been using yumi robots for It enables humans and robots to safely complete common tasks such as small electronic assembly. Kawasaki has launched a very unique and innovative dual-arm SCARA robot duaro that can work with people in various workplaces. Kawasaki is now recognized as a global leader in a wide range of industries, providing state-of-the-art machinery and robotics for the marine, air, environmental and energy sectors, with businesses ranging from marine transportation, rail and aerospace to recreational vehicles and motorcycles.ABB robot manufacturing process revealedDaqing Volvo Car Manufacturing Co., Ltd. is a vehicle manufacturing enterprise jointly established by Zhejiang Geely Holding Group Co., Ltd. and Volvo Cars (China) Investment Co., Ltd. in Daqing City, Heilongjiang Province. It mainly produces the S90 long-wheelbase luxury sedan. You must know that this However, it is the most luxurious car made in China by any car brand in the world, and it is also the first time that a high-end car made in China is exported to the US market. Today, we are going to go deep into the factory to see how these cars are manufactured by ABB robots.As Volvo”s global benchmark factory, Volvo”s Daqing factory uses a large number of ultra-high-strength boron steel materials for the S90 models, and also uses aluminum materials in many places to ensure the lightweight of the entire vehicle. In Volvo”s modern welding workshop with unified global standards, more than 200 ABB robots are used, which are widely used in side lines, main lines, door lines, roof lines, fender lines, and adjustment lines, involving handling, spot welding, automatic For punching and riveting, laser welding, piping, gluing and other applications, the main line also uses ABB”s advanced body assembly positioning solution GateFramer, which meets Volvo”s high standards and strict requirements. The S90 has a total of 5,789 welding points, of which more than 4,000 are automatically completed by robots, with an automation rate of 70%.In the fender line and roof line, Volvo also uses ABB robot safety software Safe Move to achieve human-machine collaboration, avoid unnecessary downtime of the robot, and improve production efficiency.The Daqing factory is Volvo”s global manufacturing base. The S90 models it produces not only meet the needs of the local market, but also supply major global markets such as the United States and Europe. In addition to the welding workshop, ABB Robots also provides robots, advanced applications and technical support for Volvo”s stamping and painting workshops.

5500-159C Generator Parts Speed Controller 2301A Speed

5464-654 Controller debugger generator WOODWARD

8928-5014 WOODWARD Speed Sensor Full Series

5463-140 WOODWARD generator set speed control board

9907-716 Controller debugger generator WOODWARD

9907-1106 From Woodward, USA

5463-375 Generator Parts Speed Controller 2301A Speed

5463-033 From Woodward, USA

5464-550 Controller debugger generator WOODWARD

5466-268 WOODWARD Speed Sensor Full Series

5464-206 WOODWARD 2301A Speed Control Controller

5501-465 WOODWARD Speed Sensor Full Series

5463-579 Generator Parts Speed Controller 2301A Speed

5437-078 WOODWARD generator set speed control board

9907-825 From Woodward, USA

5501-466 WOODWARD Speed Sensor Full Series

9907-166 WOODWARD Speed Sensor Full Series

9902-244 Controller debugger generator WOODWARD

5464-716A WOODWARD generator set speed control board

5461-770 WOODWARD generator set speed control board

9907-1228 WOODWARD Speed Sensor Full Series

9906-124 Controller debugger generator WOODWARD

5462-085 From Woodward, USA

5441-689 Controller debugger generator WOODWARD

8440-1884 WOODWARD Speed Sensor Full Series

8915-1146 Controller debugger generator WOODWARD

5466-1047 Generator Parts Speed Controller 2301A Speed

5463-531 WOODWARD Speed Sensor Full Series

5439-766 WOODWARD 2301A Speed Control Controller

9907-838 WOODWARD 2301A Speed Control Controller

8273-1011 From Woodward, USA

5439-076 WOODWARD Speed Sensor Full Series

8270-768 WOODWARD generator set speed control board

5466-340 WOODWARD 2301A Speed Control Controller

5437-092 Controller debugger generator WOODWARD