Description

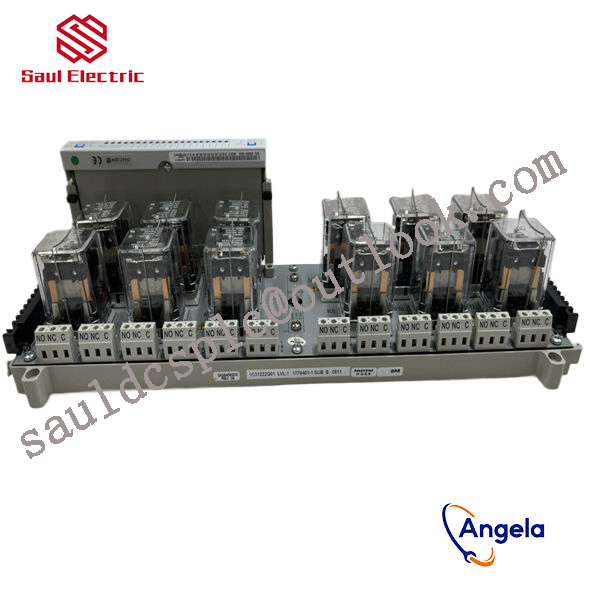

1C31127G01 Emerson Ovation Electromagnetic Output

thereby controlling external devices or circuits.

Motion controllers can be divided into three basic types based on the principle of position control, namely the presence or absence of detection feedback sensors and their detection devices: open-loop, semi closed loop, and closed-loop motion controllers.

1. Open-loop control motion controller

There is no position detection feedback device, and its execution motor generally uses a stepper motor. The biggest features of this type of motion controller are convenient control, simple structure, and low price. The displacement command signal flow issued by the motion controller is unidirectional, so there is no stability issue. However, due to the lack of feedback correction for mechanical transmission errors, the position accuracy is generally not high.

2. Semi closed loop control motion controller

The position feedback adopts a corner detection element, which is directly installed at the end of the servo motor or screw. Due to its position feedback control, high positioning accuracy can be achieved, and most mechanical transmission components are not included in the closed-loop system, thus obtaining relatively stable control characteristics. Mechanical transmission errors such as lead screws cannot be corrected through feedback, but software fixed value compensation can be used to appropriately improve their accuracy.

3. Fully closed-loop control motion controller

By using detection elements such as gratings to detect the position of the controlled unit, transmission errors in the entire mechanical transmission chain from the motor to the controlled unit can be eliminated, resulting in high static positioning accuracy. However, due to the nonlinear friction characteristics, rigidity, and clearance of many mechanical transmission links within the entire control loop, and the large dynamic response time (compared to electrical response time) of the entire mechanical transmission chain, it is difficult to calibrate the stability of the entire closed-loop system, and the design and adjustment of the motion controller are also quite complex.

responsible for processing signals from on-site sensors or driving actuator actions. For example, they may need to cooperate with devices such

as BANNER travel switch T30UIPB to receive their transmitted position signals; Or by controlling components such as Burkert solenoid valve 00131421, the on/off of fluid media can be precisely managed.

these modules integrate more complex logic processing capabilities. The core task of a pressure switch is to detect whether the pressure

has reached a preset threshold and output a switch signal. Its function is highly specific and fixed. And modules 1C31127G01 and 1

C31219G01 have the ability to comprehensively judge multiple such switch signals and transmitter signals (such as transmitter 1066-P-HT-60),

and output complex control instructions according to internal logic.