Description

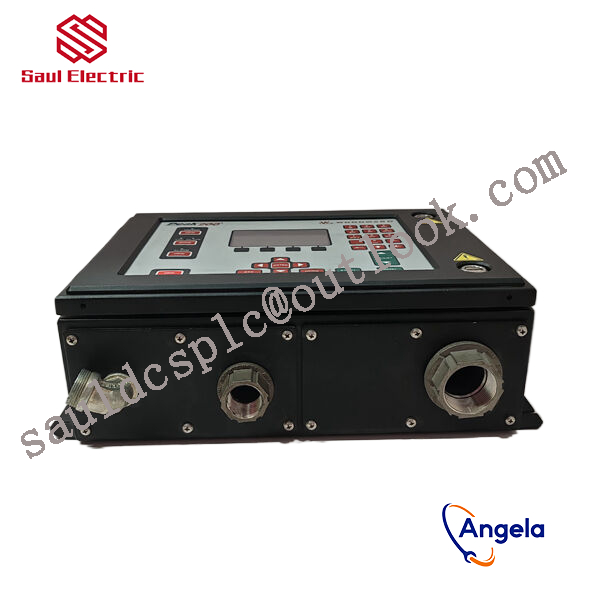

1680-649 WOODWARD 2301A Speed Control Controller

1680-649 Product Introduction

Non differential regulation is mainly used for constant speed control and is suitable for single machine operation or multiple prime movers working together in an isolated power grid. Differential regulation provides more control flexibility.

further enhancing its performance and application range.

rich additional functions, and high-precision output signals. Whether it is in the fields of generator sets, compressors, pump stations, or ships and locomotives, it can effectively ensure the stable operation of equipment within the set range.

power measurement level 1, editable screen, multi interface toolkit connection, etc. All details can be found in Woodward easyYgen manual 37582A

The rated operating temperature range of this model is -20 to 70 ° C; the rated temperature range of the LT model is -40 to 70 ° C, suitable for outdoor use.

1680-649 is equipped with a monitor (not available on the 3100 model) and is designed for front panel installation.

The built-in HMI has a color LCD and soft keys (now with dedicated buttons) for direct control of the 1680-649 device. Multi level password protection can prevent unauthorized changes.

The generator set has four operating modes and the option to configure a manual circuit breaker control device.

How to use 1680-649?

What is 1680-649 used for?

1680-649 Customs Code

Machine replacement has become a noun of the times. The gradual disappearance of the demographic dividend has created opportunities for robots. In particular, some jobs in harsh environments require robots to take over. In May this year, the Guangdong Electric Power Research Institute of China Southern Power Grid successfully launched its first inspection robot. The product uses 3D laser navigation technology, can successfully bypass obstacles, and has passed field tests.It is reported that the substation inspection robot can be connected with the Guangdong Power Grid centralized control platform to realize remote dispatching of substations and power supply bureaus. Through the networking function, the robot can transmit on-site data to the centralized control center for technicians to analyze and implement relevant measures. At the same time, this will greatly improve the efficiency of substation inspections and make up for the shortcomings of manual inspections.Comment: Due to the scattered and remote locations of substations and certain safety hazards in high-voltage facilities, manual inspection has brought certain difficulties. China Southern Power Grid”s substation inspection robots can effectively replace workers in power station inspections and hand over these low-value tasks to machines, which can also reduce labor costs and promote the improvement of the overall automation level of the power grid.The third factory of Yaskawa Robot Co., Ltd. was completedFor global robot manufacturers, China is an indispensable market, and major robot manufacturers have entered and deployed in China. On June 15, Yaskawa (China) Robotics Company, one of the four largest families in the world, held the completion ceremony of its third factory in Changzhou. The new factory will increase the production of 500 industrial robots per month for Yaskawa Group, bringing Yaskawa”s production capacity in China to 18,000 units per year.According to Yaskawa Robot”s description, the new factory is to meet the rising robot market made in China, and it plans to establish a robot R&D center in the new factory to develop robot products suitable for local needs based on China”s local characteristics. The investment and construction of this factory indicates that Yaskawa will increase its investment in China”s robot industry and prepare for the rapidly growing market demand in the future.Comment: China’s industrial robot sales increased by 58% last year, making it the world’s largest industrial robot market. With the expansion of policies and robot application fields, China’s robot industry will have greater room for growth in the future. Yaskawa is building a new factory and expanding its robot production capacity in China. This shows the company”s confidence in the Chinese market and also shows Yaskawa”s intention to seize the Chinese market.Collaborative robot company Rethink Robotics announces closureUnder the wave of transformation and upgrading of the manufacturing industry, collaborative robots are playing an increasingly important role. As a leader in the field of global collaborative robots, Rethink Robotics has two intelligent collaborative robots, Baxter and Sawyer. These two robot products are among the best in the world . At the leading level, it was once regarded as the most promising intelligent collaborative robot. However, sales of Baxter and Sawyer robots were unsatisfactory, and in October this year the company suddenly announced its closure, a move that caused lamentation in the industry.It is reported that the products of Rethink Robotics have not really opened up in the market. This may be related to the design of the product. Although the functions of intelligent collaborative robots are powerful, they are also very expensive and are uncompetitive compared with low-cost collaborative robots on the market. . Rethink Robotics invested heavily in the development of this intelligent collaborative robot, but insufficient funds forced the company to cease operations. Subsequently, all patents and trademarks of Rethink Robotics and its software platform were transferred to the German Hahn Group, and some employees were taken over by the competitor company Univers al Robots.Comment: The robot industry is a big cake, attracting competition from various capital and technology companies, and also accelerating competition in the industry. The design of a product needs to consider the actual needs of the market. No matter how advanced the function is, if the cost and the actual market environment are not taken into consideration, the product may be just an ornament. Although Rethink Robotics received US$150 million in funding and created the world”s most advanced collaborative robot products, the market could not accept its high price and ultimately failed.JD.com and Newstar cooperate to develop end-of-line delivery robotsRobots have great prospects in the field of logistics, especially today with the development of e-commerce. Robots can play an important role in warehouse sorting, handling, storage, transportation, express delivery and other processes. The market opportunities for logistics robots are growing. In September this year, JD.com and Newstar signed a strategic cooperation agreement. The two parties will jointly promote the mass production of terminal delivery robots and intelligent robot services.As a Chinese e-commerce giant, JD.com urgently needs to reduce the cost of logistics and distribution. Logistics robot products can replace human labor and transport goods to their destinations, which will greatly reduce the cost of e-commerce operations and improve the overall intelligence of the logistics system. Newstar is a leader in the field of robots. Cooperation between the two can accelerate the implementation of logistics robot projects.Comment: Rising labor costs have forced companies to consider using robots. Robots have expanded in application scenarios from manufacturing to public life. In the logistics industry, the potential value of robots is huge. Among them, terminal delivery robots can solve the problem of the last mile of logistics and express delivery, reduce manpower investment and improve the intelligent experience of services. JD.com and Newstar, one is an e-commerce giant and the other is an expert in the field of robotic automation. The cooperation between the two can achieve the effect of complementary advantages and will accelerate the process of smart logistics.ABB invests US$150 million to build the world”s most advanced robot factoryOn October 27, the world”s industrial robot giant ABB announced that it will invest US$150 million to build the world”s largest and most advanced flexible robot factory in Shanghai. This demonstrates the upgrade of ABB”s strategic investment in China and its optimism about China as the world”s largest robot factory. The prospects of the robot market. The new factory will adopt ABB”s connected digital technology, including ABB Ability solutions, collaborative robots, artificial intelligence and other advanced technologies.In addition, ABB has also signed a strategic cooperation agreement with the Shanghai government to support the development of Shanghai”s industry, energy, transportation and other fields. Shanghai is the largest hub in China”s robotics industry, with giants such as FANUC, ABB, Yaskawa, and KUKA all opening factories one after another. The construction of ABB”s new factory will expand ABB”s production capacity in China and help it seize the Chinese robot market share.Comment: The global robot industry has entered a rapid growth channel, especially China, as the world”s largest robot market, attracting the deployment of many domestic and foreign manufacturers. ABB”s large investment in building a new factory in China is precisely because it sees the potential of China”s robot market. China is a major manufacturing country. Once the demand for robot applications in various industries is opened, the market prospects will be unlimited.

9903-109 From Woodward, USA

5464-536 WOODWARD 2301A Speed Control Controller

5462-762 Generator Parts Speed Controller 2301A Speed

9907-124 From Woodward, USA

9907-954 Controller debugger generator WOODWARD

8239-005 Controller debugger generator WOODWARD

5439-730 Controller debugger generator WOODWARD

9905-860 WOODWARD Speed Sensor Full Series

5441-889 Controller debugger generator WOODWARD

A8523-210 Controller debugger generator WOODWARD

5453-278 From Woodward, USA

5463-432 WOODWARD generator set speed control board

5461-651 Controller debugger generator WOODWARD

9907-1106 WOODWARD generator set speed control board

8915-948 From Woodward, USA

A8516-042 WOODWARD Speed Sensor Full Series

8290-184 WOODWARD 2301A Speed Control Controller

8915-046 From Woodward, USA

9905-973 From Woodward, USA

SPM-D11 8440-1706B WOODWARD Speed Sensor Full Series

9907-005 WOODWARD 2301A Speed Control Controller

8915-011 Generator Parts Speed Controller 2301A Speed

9907-561 WOODWARD generator set speed control board

5437-281 WOODWARD 2301A Speed Control Controller

3313-055 Generator Parts Speed Controller 2301A Speed

5405-819 WOODWARD Speed Sensor Full Series

8444-1067 Controller debugger generator WOODWARD

5463-780 WOODWARD Speed Sensor Full Series

5503-279 Generator Parts Speed Controller 2301A Speed

5415-816 WOODWARD 2301A Speed Control Controller

8236-027 Generator Parts Speed Controller 2301A Speed

8200-1204 From Woodward, USA

9905-864 WOODWARD 2301A Speed Control Controller

9907-147 WOODWARD Speed Sensor Full Series

A8516-042 WOODWARD 2301A Speed Control Controller

9905-211 From Woodward, USA

9662-610 From Woodward, USA

8440-1809 From Woodward, USA

5463-796 Controller debugger generator WOODWARD

5462-966 WOODWARD 2301A Speed Control Controller

8273-1011 WOODWARD 2301A Speed Control Controller

8580-085 Generator Parts Speed Controller 2301A Speed