Description

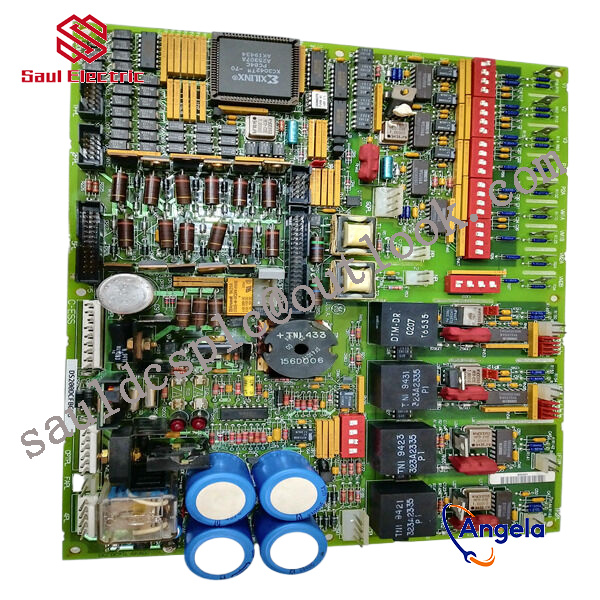

IS220UCSAH1A Product Introduction

The specific application scope of the product

will depend on the needs of system integration and industrial application, but generally speaking, this type of embedded controller module can be applied to the following categories:

manufacturing processes, etc.

monitoring and control system.

of the controller module, as well as the specific needs of the customer.

designed to manage gas or steam turbines.

It has a CIMPLICITY graphical interface and an HMI with software suitable for running heavy-duty turbines.

be installed at the bottom of the cabinet. For a small setup that is easy to serve a triple redundant system, up to three components can be installed side by side.

he board can operate within a temperature range of 0 to 65 degrees Celsius without the need for a fan for cooling. NFPA Class 1. This board can be used for two applications.

3.3 Design of computer control softwareThis type of control software runs on the computer and is mainly used for remote operation. It has multiple functions such as parameter setting, control operation, data collection and storage, status detection and alarm, etc. Its interface is shown in Figure 3.The system shown in Figure 3 contains four independent control channels, and the software can manage and configure the test plan based on parameter information. That is: for each test plan, you can configure different test plans and set different test parameters through the “Configuration” operation. You can also create new plans, save and modify plans, open existing plans, and delete plans.The software also sets up quick operations, which can quickly start and stop work according to the channel configuration, and can detect the working status of each channel in real time.3.4 Design of touch screen softwareThe touch screen software is mainly used for local control and runs in the touch screen controller. While the computer control software has similar functions, it also has the setting function of local control priority or remote control priority. The default is remote control priority. The login interface and test operation interface are shown in Figure 4 and Figure 5 respectively.3.5 Design of PLC softwareAs the core of this control system, PLC is mainly responsible for the following aspects:Responsible for sending corresponding control parameters and instructions to the frequency converter, and at the same time obtaining the status of the transmission system through the ProfibusDP bus protocol.Communicates with the touch screen through serial communication, responds to local control instructions, and feeds back system status to the touch screen as a slave computer for local control. Programming between the touch screen and PLC is performed by directly accessing the PLC variable address.It communicates with the remote control computer through the OPC[5] communication method based on the external network, responds to the remote control instructions, and feeds back the system status to the remote control computer as the remote control slave. Programming between the remote control program and the PLC is performed by accessing the PLC variable name.Process the emergency signal and control the inverter to slow down and unload according to the default parameters.Figure 4 Login interfaceFigure 5 Test interface3.6 Frequency converter settingsIn general, the inverter will be equipped with an optional operation panel. Before using the local or remote control program to operate the inverter, you must first perform the basic settings of the inverter, as follows:Switch the control mode to local control and set the inverter address according to the inverter user manual.Set the inverter for remote control and select the communication mode.Set the frequency converter to use an encoder, and connect the motor for self-test matching operation.Set the speed control mode of the inverter, such as speed control or torque control.After completing the basic parameter settings, switch to the remote control state and wait for remote control.4 ConclusionThis system implements a universal belt-turning mechanism that utilizes frequency conversion control technology. You can use the local touch screen to control the inverter to control the motor rotation and obtain corresponding feedback, or you can use remote control to control the inverter to achieve the same control effect as the local touch screen, even in view of the computer function The richness allows you to obtain more system information and set more control states. In addition to local touch screen control and remote control, the overall structure of this system can also be split into the most basic transmission structure to complete the control, that is, the motor is controlled directly through the control panel of the frequency converter to achieve the most basic and direct control. Therefore, this system can be used as a basic framework structure to meet all similar control requirements, and obtain different levels of usage requirements through different levels of hardware configuration, which has universal reference significance.

IS200ERBPG1A High performance processor module GE

IS200ESYSH3A Gas turbine system Mark VI

IS215ISBBH1A I/O excitation redundant module GE

DS200DSFBG1ACB Gas turbine system Mark VI

IS200DTAIH1ACC Processor/Controller Mark VI System

IS200VPWRH1A GE power control board

IS200JPDPG1A Processor/Controller Mark VI System

DS200DCFBG1BNC GE power control board

IS200XDIAG1A High performance processor module GE

IS210AEPSG2BBA Gas turbine system Mark VI

DS200FGPAG1A Processor/Controller Mark VI System

DS200PCCAG6ACB High performance processor module GE

IS200TRLYH1B Gas turbine system Mark VI

IS215VCMIH2CA Processor/Controller Mark VI System

IS215VCMIH1B GE power control board

IS200VCMIH1BCC High performance processor module GE

IS200TTURH1CED Gas turbine system Mark VI

DS200SDCCG4A I/O excitation redundant module GE

IS420YAICS1B Processor/Controller Mark VI System

IS200JPDSG1ACBGE I/O excitation redundant module GE

IS420ESWAH1A Gas turbine system Mark VI

IS200ICBDH1BAA Processor/Controller Mark VI System

IS200AVGBG1A Gas turbine system Mark VI

IS215ACLEH1BC GE power control board

IS230SNAIH4A GE power control board

IS200VTCCH1CBD Gas turbine system Mark VI

IS200TBAIH1CDC GE power control board

IS200ADIIH1A From General Electric in the United States

IS420PVIBH1B From General Electric in the United States

IS200ACLEH1BCB Gas turbine system Mark VI

IS200TREGH1B Processor/Controller Mark VI System

IS420UCPAH1A Gas turbine system Mark VI

IS200CPFPG1A High performance processor module GE

DS200FGPAG1AHD High performance processor module GE

DS200SLCCG1ABB I/O excitation redundant module GE

IS220PSVOH1A Processor/Controller Mark VI System

IS215GBIAH1A GE power control board

IS200TRPSH1A GE power control board

DS200TCTGG1AFF From General Electric in the United States

IS200EPSMG2A High performance processor module GE

IS200SAMBH1A Processor/Controller Mark VI System

IS420UCSCS2A GE power control board

IS200DTURH1ACC Processor/Controller Mark VI System

IS200DSFCG1A High performance processor module GE

IS200ERIOH1AAA GE power control board

IS200GGXDG1AA Gas turbine system Mark VI

IS200AEPAH1BCA I/O excitation redundant module GE

IS200RAPAG1BAA GE power control board

IS220YSILS1BB High performance processor module GE

IS220PTURH1A High performance processor module GE

DS200DCFBG1BLC High performance processor module GE

DS200TCPDG1B GE power control board

DS200ADMAH1A GE power control board