Description

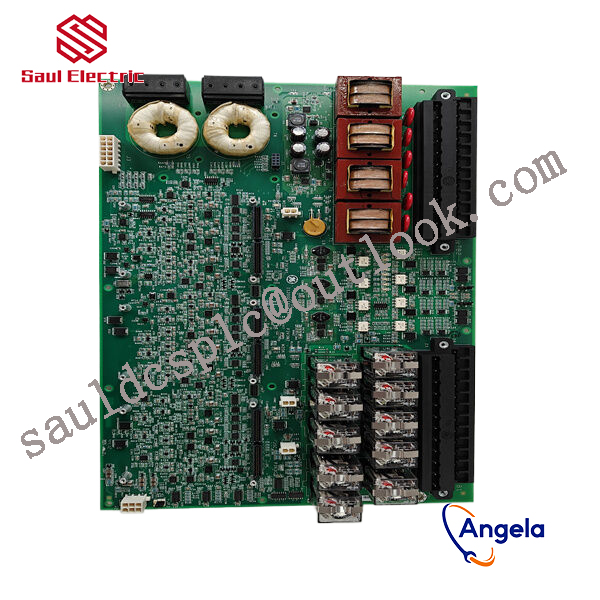

IS220PRTDH1B Product Introduction

The specific application scope of the product

will depend on the needs of system integration and industrial application, but generally speaking, this type of embedded controller module can be applied to the following categories:

manufacturing processes, etc.

monitoring and control system.

of the controller module, as well as the specific needs of the customer.

designed to manage gas or steam turbines.

It has a CIMPLICITY graphical interface and an HMI with software suitable for running heavy-duty turbines.

be installed at the bottom of the cabinet. For a small setup that is easy to serve a triple redundant system, up to three components can be installed side by side.

he board can operate within a temperature range of 0 to 65 degrees Celsius without the need for a fan for cooling. NFPA Class 1. This board can be used for two applications.

In the Internet of Things era, look at the IOT strategic deployment of the “four major families” of industrial robotsWhen we talk about Industry 4.0 or smart manufacturing, we cannot help but mention the “four major families” of robots – KUKA, ABB, FANUC, and Yaskawa, because as the industrial robot companies with the highest level of intelligence at present, they are in the industry They have important influence. In the era of the Internet of Things, what are these four major families doing?As a relatively mature product, industrial robots are difficult to judge from the perspective of ordinary users. Especially in today”s era, it is impossible to create a generational gap through technology.Just like when someone asks about the advantages and disadvantages of the car-making technologies of Mercedes-Benz and BMW, all I can say is, “It doesn”t matter if you ride in a Mercedes-Benz or drive a BMW.” Comparing industrial robots to car-making, most of the key technologies used in car-making must be shared by Mercedes-Benz and BMW. The differences in other “marketing technologies” will not affect the technological competition pattern.So what will industrial robot manufacturers mainly rely on to widen the gap in the future? There is only one answer, the Internet of Things strategy. Without realizing it, KUKA, ABB, FANUC, and Yaskawa, the four major industrial robot giants, have already been stationed in the field of Internet of Things and are ready to go. KUKA(Midea)On December 30, 2016, Midea Group’s tender offer for the shares of Germany’s KUKA Group (KUKA), the world’s leading provider of intelligent automation solutions, through MECCA InternaTIonal (BVI) Limited, has received approval from all relevant regulatory authorities.At the annual meeting of Midea Group on January 12, 2017, Fang Hongbo, Chairman of Midea Group, emphasized the industrial significance of Midea’s acquisition of KUKA: In the future, Midea will build a second industrial segment besides the home appliance industry, namely the robotics and industrial automation industry segment. This is The new growth point of beauty.The annual meeting invited KUKA CEO TIll Reuter, who has just entered the Midea system, to give a speech. When explaining the core strategic goals for the future, Reuter mentioned the two concepts of “intelligent machines” and “digital areas”, which are the two concepts that run through the Internet of Things technology in the company”s business:Intelligent machines: Among the industrial robots manufactured by KUKA, they are equivalent to advanced robots with both autonomy and mobility. Soon a large number of industrial robots will “step out of the work cage that is isolated from humans” and begin to work closely with humans, further improving their flexibility. Reuter said that as industrial robots continue to develop, smart machines with better autonomy and mobility will emerge.Digital area: It is a solution that combines the knowledge related to production processes of various industries that KUKA has cultivated in the past with the most cutting-edge IT. Reuter said: “We are familiar with the production processes of products such as cars and aircraft. We want to connect our technical experience with IT to provide customers with intelligent systems.” Reuter said that by optimizing intelligent systems, that is, complex systems based on big data analysis, reducing downtime and predictive maintenance of various production systems, new business models can be created and a highly integrated value chain can be built.According to IFR data, in the field of automobile manufacturing, KUKA robots have the largest market share in the world. We might as well start with the automotive industry and show you how KUKA uses the “Internet of Things box” to construct the Jeep Wrangler”s body-in-white workshop into an IIoT (Industrial Internet of Things) factory.

IS420UCSCS2A-B From General Electric in the United States

IS200TVBAH2ACC I/O excitation redundant module GE

IS200JPDSG1ACBGE From General Electric in the United States

IS220PDIIH1B GE power control board

DS200LDCCH1AGA GE power control board

IS200BLIGH1A Gas turbine system Mark VI

IS200ERRBG1A From General Electric in the United States

IS200DSPXH1D I/O excitation redundant module GE

IS200ERIOH1ACB From General Electric in the United States

IS200TBTCH1CBB High performance processor module GE

IS200DAMAG1B From General Electric in the United States

IS200VAICH1DAA From General Electric in the United States

IS200HFPAG2A I/O excitation redundant module GE

IS200RCSAG1ABB GE power control board

IS200TREGH1BDC Processor/Controller Mark VI System

IS210DTAIH1A Processor/Controller Mark VI System

IS230TNTRH1C Gas turbine system Mark VI

DS200TCEAG1BNE I/O excitation redundant module GE

IS200JPDDG1A Processor/Controller Mark VI System

IS200TRLYH1BGF GE power control board

DS200TCEAG1BTF High performance processor module GE

IS200TRLYH1C High performance processor module GE

IS210AEBIH1ADC From General Electric in the United States

IS200ESYSH3ABB Gas turbine system Mark VI

IS200HFPAG2ADC GE power control board

IS200BICRH1A GE power control board

IS220PRTDH1B Processor/Controller Mark VI System

DS200ACNAG1ADD High performance processor module GE

DS200TCRAG1ABB GE power control board

DS200SDCCG4AFD High performance processor module GE

DS200GDPAG1AKF High performance processor module GE

DS200TCCAG1BAA I/O excitation redundant module GE

DS215TCDAG1BZZ01A From General Electric in the United States

GDS1168-PFF-PA-NF Processor/Controller Mark VI System

IS210MACCH2AEG High performance processor module GE

IS200EGPAG1B Gas turbine system Mark VI

IS200SPROH1AAB Processor/Controller Mark VI System

DS200UPSAG1A Processor/Controller Mark VI System

DS200TBQCG1AAA High performance processor module GE

DS200SPCBG1ADC I/O excitation redundant module GE

DS200IIBDG1A High performance processor module GE

IS200TRLYS1BGG High performance processor module GE

IS215UCVFH2AB High performance processor module GE

DS200SDCCG5A GE power control board

IS210AEBIH3B Gas turbine system Mark VI

IS200DAMDG2A Processor/Controller Mark VI System

DS3820LT4AICIA From General Electric in the United States

IS400JPDHG1ABB Gas turbine system Mark VI

IS200VTCCH1CBC GE power control board

DS200TCDAH1B Processor/Controller Mark VI System

IS210AEACH1A I/O excitation redundant module GE

DS200LDCCH1AGA Processor/Controller Mark VI System

IS410TRLYS1F High performance processor module GE

IS220PRTDH1B High performance processor module GE

IS215SECAH1A I/O excitation redundant module GE

IS200TBTCH1C I/O excitation redundant module GE

DS200TCQCG1BKG Gas turbine system Mark VI

IS200BPVCG1B I/O excitation redundant module GE

IS210BPPBH2B From General Electric in the United States

IS200EPDMG1ABA I/O excitation redundant module GE

IS200STCIH6ADD Gas turbine system Mark VI

IS200VCRCH1BBB GE power control board

IS200BPIIH1AAA High performance processor module GE

IS420YDOAS1B Processor/Controller Mark VI System

IS210AEAAH1B GE power control board

DS200TCDAG1PR5A Processor/Controller Mark VI System

IS200DAMDG2AAA Processor/Controller Mark VI System

DS200SDCCG4AFD From General Electric in the United States

IS200ICBDH1ABB From General Electric in the United States

DS200ACNAG1ADD Processor/Controller Mark VI System