Description

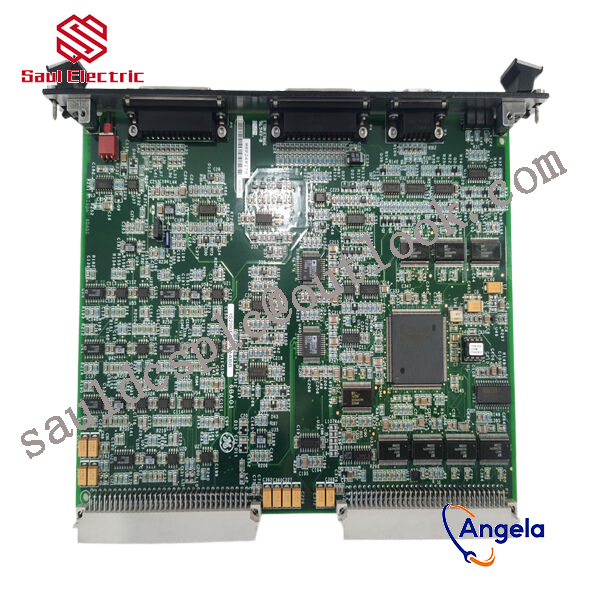

IS220PDIAH1B Product Introduction

The specific application scope of the product

will depend on the needs of system integration and industrial application, but generally speaking, this type of embedded controller module can be applied to the following categories:

manufacturing processes, etc.

monitoring and control system.

of the controller module, as well as the specific needs of the customer.

designed to manage gas or steam turbines.

It has a CIMPLICITY graphical interface and an HMI with software suitable for running heavy-duty turbines.

be installed at the bottom of the cabinet. For a small setup that is easy to serve a triple redundant system, up to three components can be installed side by side.

he board can operate within a temperature range of 0 to 65 degrees Celsius without the need for a fan for cooling. NFPA Class 1. This board can be used for two applications.

ABB launches new AR app to promote robotic automation in enterprisesThe new viewer has also been updated into ABB”s RobotStudio offline programming software. It can be used to inspect any model created in RobotStudio, giving users a better understanding of the size of the robot or robot cell. , thereby appropriately deploying robots so that they can be integrated into existing production equipment.With the support of AR technology, customers can use this App to project the model plan into the actual production environment in its original size, and then rotate the model from different angles to achieve the best deployment effect.In addition to simulating the actual delivery effect of the robot, the timeline function of this observer app also allows users to check the cycle time and quickly reach a certain time point in the simulation animation, allowing users to promptly discover ways to enhance performance or identify potential problems.The AR viewer is an ideal operating tool for companies that are new to robotic automation, or that have previously lacked the time and resources to start robot installations.Antti Matinlauri, head of product management for robotics at ABB, said: “We know from conversations with small and medium-sized enterprises that many currently want to implement some form of robotic automation, but they are not sure where to start. RobotStudio is what we offer them The most intuitive digital tool is designed to help them simplify the installation and use of robots. The AR viewer application launched this time is designed to allow customers to better master the use of RobotStudio and help them understand how to introduce robots before investing. production, and how automation will increase productivity and flexibility in existing processes.”Highlights from the pastThe industrial control giant launches its smallest industrial computer yet, just the size of the palm of your hand!How did Inovance Technology secure its position as the king of the domestic industrial control industry?SIASUN Robotics plans to raise 1.8 billion to build new semiconductor equipment and system projects[Breaking News] The Vice President of Gree Electric Appliances suddenly resigned naked. What is the reason?Limited time download | 11G Xinjie complete set of video learning materials (PLC+touch screen+manual+software…)!Fieldbus communication technology between PLC and ABB frequency converterProfibus is one of the most successful fieldbuses in current industrial control systems and has been widely used. It is an open fieldbus that does not depend on the manufacturer. Various automation equipment can exchange information through the same interface protocol. Profibus-DP (Distributed I/O System) is an optimized module with a high data transmission rate and is suitable for communication between the system and external devices, especially remote I/O systems. suitable. It allows high-speed periodic small-batch data communication and is suitable for time-critical automated control systems. The Profibus-DP fieldbus system enables many field devices (such as PLCs, intelligent transmitters, and frequency converters) to conduct two-way multi-information digital communication on the same bus. Therefore, control and measurement systems produced by different manufacturers can be easily connected to each other to form a communication network. . Jinan Iron and Steel Baode Color Plate Co., Ltd. is a large-scale color plate production base with an annual output of 200,000 tons invested and built by Jinan Iron and Steel Group Corporation in 2003. The curing furnace, thermal oil furnace, and gas system in the gas hydrogen production in its production line must pass the gas. The gas pressurizer must perform secondary pressurization to meet the production process requirements. The gas pressurizer control system adoptsUsing Profibus-DP process field bus communication technology solution, the automation control unit and frequency converter adopt products from different manufacturers, respectively using Siemens” S7-300 PLC and ABB”s ACS600 frequency converter.2 System configuration and communication protocol(1) System configurationThis system uses related products of Siemens and ABB to realize the communication and control principle of the all-digital AC speed control system in the Profibus-DP network. The attached picture shows the network configuration diagram of the Profibus-DP network of the system, in which the PLC is SIMATIC S7-315-2DP of Siemens, the frequency converter is the ACS600 series, and NPBA-12 is the communication adapter matched with the frequency converter. The programming software is STEP7 V5.2 software, which is used for S7-300 PLC programming and Profibus-DP network configuration and communication configuration. The upper computer screen operation uses WinCC5.1 for screen programming and operation, and the communication with the PLC uses Ethernet communication.(2) Communication protocolIn this system, S7-300 PLC serves as the master station and when the frequency converter serves as the slave station, the master station transmits operating instructions to the frequency converter and at the same time accepts the operating status and fault alarm status signals fed back by the frequency converter. The frequency converter is connected to the NPBA-12 communication adapter module, connected to the Profibus-DP network as a slave station, and accepts control from the master station SIMATIC S7-315-2DP. The NPBA-12 communication adapter module stores the process data received from the Profibus-DP network into the bidirectional RAM. Each word is addressed. The bidirectional RAM on the frequency converter side can be sorted by the addressed parameters and sent to the frequency converter. Write control words, setting values or read actual values, diagnostic information and other parameters.From a software perspective, the core content of the inverter fieldbus control system is the fieldbus communication protocol. The data telegram structure of the Profibus-DP communication protocol is divided into protocol header, network data and protocol layer. The network data, namely PPO, includes parameter values PKW and process data PZD. Parameter values PKW are some function codes to be defined when the frequency converter is running; process data PZD are some data values to be input/output during the operation of the frequency converter, such as frequency given value, speed feedback value, current feedback value, etc. Profibus-DP has two types of network PPO: one is PZD without PKW and has 2 or 6 words; the other is PZD with PKW and 2, 6 or 10 words. The purpose of classifying and defining network data in this way is to complete different tasks, that is, the transmission of PKW and the transmission of PZD do not affect each other and work independently, so that the frequency converter can operate according to the instructions of the upper-level automation system.3 STEP7 project system configuration and communication programming

IS200VSVOH1B From General Electric in the United States

IS230TVBAH4A High performance processor module GE

IS210AEBIH1BAA GE power control board

IS200VRTDH1DAC From General Electric in the United States

IS200TSVCH2ADC Gas turbine system Mark VI

DS200LRPAG1AAA Gas turbine system Mark VI

DS215TCQAG1BZZ01A I/O excitation redundant module GE

DS200DCFBG1BLC I/O excitation redundant module GE

IS210BPPCH1AC Processor/Controller Mark VI System

IS210AEBIH1BED From General Electric in the United States

IS200ISBEH2ABB GE power control board

IS200VPWRH1AF GE power control board

IS200ERRRH1A Gas turbine system Mark VI

IS200VTCCH1CBB High performance processor module GE

IS200TBACIH1B Gas turbine system Mark VI

IS200VTCCH1CBB GE power control board

IS200RCSBG1BAA From General Electric in the United States

IS200ICIAH1ABB From General Electric in the United States

IS200TREGH1B GE power control board

IS215UCVEH2A Processor/Controller Mark VI System

IS200ISBBG2AAB Processor/Controller Mark VI System

IS200TREGH1BDB Gas turbine system Mark VI

IS220PVIBH1A I/O excitation redundant module GE

DS200CTBAG1ACC From General Electric in the United States

IS200BPIAG1AEB From General Electric in the United States

IS200ERRBG1A High performance processor module GE

IS200VSVOH1BDC I/O excitation redundant module GE

DS200TCCAG1BAA GE power control board

DS200TCTGG1AFF GE power control board

IS200EXHSG3AEC High performance processor module GE

IS200TPROS1CBB High performance processor module GE

IS200EXAMG1A Gas turbine system Mark VI

IS220PDOAH1B I/O excitation redundant module GE

IS200WETBH1BAA GE power control board

IS200VCMIH1BCC Processor/Controller Mark VI System

DS200UCPBG6AFB Processor/Controller Mark VI System

IS200TRLYH2C I/O excitation redundant module GE

DS200TCQAG1BEC Processor/Controller Mark VI System

IS215SUCVEH2AE Gas turbine system Mark VI

IS230TBAIH2C High performance processor module GE

IS200ECTBG1ADE I/O excitation redundant module GE

IS200JPDPG1A GE power control board

IS200TBCIH1BBC High performance processor module GE

IS200TREGH1BDC I/O excitation redundant module GE

IS215UCVEM09A Gas turbine system Mark VI

IS200BICIH1ADB Processor/Controller Mark VI System

IS215ACLEH1A High performance processor module GE

IS200SAMBH1A Gas turbine system Mark VI

IS200TREGH1B I/O excitation redundant module GE

IS220PTCCHIA Processor/Controller Mark VI System

IS215PCMIH1AC Gas turbine system Mark VI

IS220PTURH1A GE power control board