Description

IS200TREGH1BDC Product Introduction

The specific application scope of the product

will depend on the needs of system integration and industrial application, but generally speaking, this type of embedded controller module can be applied to the following categories:

manufacturing processes, etc.

monitoring and control system.

of the controller module, as well as the specific needs of the customer.

designed to manage gas or steam turbines.

It has a CIMPLICITY graphical interface and an HMI with software suitable for running heavy-duty turbines.

be installed at the bottom of the cabinet. For a small setup that is easy to serve a triple redundant system, up to three components can be installed side by side.

he board can operate within a temperature range of 0 to 65 degrees Celsius without the need for a fan for cooling. NFPA Class 1. This board can be used for two applications.

“This partnership is exciting. By becoming the center for ABB robotics to enter the medical field, Texas Medical Center will continue to advance innovative collaborations with cutting-edge industry partners.” said Bill McKeon, President and CEO of Texas Medical Center. Operating a medical city in a city with an average of 10 million patients per year must prioritize efficiency and precision and develop processes that are easily replicable. By partnering with ABB to leverage first-of-its-kind R&D facilities, Texas The Medical Center is committed to making this happen.””We are proud to work with world-leading partners to develop collaborative robotic systems for the hospital of the future and test them in real laboratories to ensure value for medical professionals. At the same time, we will drive innovation, To change the way medical laboratories around the world operate.” An Shiming said, “A key element of ABB”s long-term development strategy is to continue to invest and innovate in the field of service robots and introduce our automation expertise into new areas such as healthcare. And continue to expand markets based on business in the automotive and electronics industries.”1 OverviewAmong many bus standards, various buses are called standards. However, in industries or fields where market competition cannot be divided, various buses penetrate each other. For example, DeviceNet is widely used in the automotive, material handling and manufacturing processing industries, but in Europe, the Profibus standard is also a strong competitor in these fields and occupies an absolute share. In addition, the Profibus standard is also widely used in some specific industries, such as the application of Profibus DP in automobile factories. However, a very interesting phenomenon is that the German CAN open bus itself is also used in the automotive industry. However, no matter how you look at it, the entire market can basically be divided into two categories: process industry and manufacturing industry.As industrial enterprises continue to invest in achieving faster and more efficient production and operation, the number of intelligent devices hanging on these different buses is increasing rapidly. The application of buses can indeed bring vitality and powerful business processing capabilities to end-user enterprises, but it also brings a problem to intelligent device suppliers: they must design different bus products based on numerous buses to meet the needs of various industries. There is a need for a bus; but the data interfaces of the products are all hardware-based. It is not advisable in terms of manufacturing cost to design a product with multiple types of hardware. In addition, control wiring in fieldbus is a time-consuming task and is not easy to succeed in the installation project. This complexity of work is obviously contrary to today”s trend of easier equipment operation. System integrators look forward to a plug-and-play solution that eliminates the need to read through thick product specification sheets provided by suppliers. This is actually a demand for flexibility and simplification of industrial communications. Therefore, ABB designs and produces a product (FieldBusPlug-FBP) that can easily and quickly connect to any bus system to simplify the entire fieldbus, as shown in Figure 1. In fact, FBP is a bus adapter .Figure 1 Fieldbus Adapter (FBP)2. Functions of FBP systemThe FBP system can connect switchgear and other similar elements, such as motor protection and control equipment to sensors , in a simple and effective way with the usual automation systems ( PLCs ) via a bus adapter of any protocol. wait. These switching devices are independent of the bus used. Through selected bus cables (FBP cables), connections to various bus adapters can be established.ABB FBP bus adapter can support five bus adapters: Profibus-DP, CANopen, Modbus-RTU, DeviceNet and AS-i. The appearance and connection methods of these five bus adapters are the same. It provides convenience for unified use and selection . As shown in Figure 2, the DeviceNet bus adapter is selected for communication.Figure 2 Connection diagram of multi-substation equipment and PLC system3. Characteristics of FBP systemToday”s automation applications not only require intelligent products, but also need to be able to communicate with each other to implement network functions, and the bus is undoubtedly the communication method chosen by many current automation equipment. When you walk into any manufacturing plant , process company, or energy company, you will easily find hundreds of actuators and sensors communicating with their controllers through a bus.3.1 Simple and flexible bus systemOne device is suitable for all bus types. Every device and every functional module in the product line contains a neutral bus adapter interface. With selected bus adapters and cable glands and pre-connected cables, it is very easy to establish reliable and flexible communication and connections, as shown in Figure 3.

DS200PLIBG2ACA From General Electric in the United States

IS200ICIAH1ABB High performance processor module GE

IS200ERDDH1ABA From General Electric in the United States

DS200SHVMG1A I/O excitation redundant module GE

IS200VCMIH1B Gas turbine system Mark VI

IS200VCCCH1B High performance processor module GE

IS410STCIS2A I/O excitation redundant module GE

IS200VVIBH1B Gas turbine system Mark VI

IS210AEBIH1ADB Processor/Controller Mark VI System

DS3820PSCB1C1B From General Electric in the United States

DS200PCCAG7A High performance processor module GE

IS200BPIIH1A Gas turbine system Mark VI

IS215WEMAH1B High performance processor module GE

DS200TCQAG1B Gas turbine system Mark VI

IS230TDBTH6A GE power control board

IS220PPROH1A From General Electric in the United States

IS200DSPXH1D From General Electric in the United States

IS200TBCIH1B From General Electric in the United States

IS220PAOCH1A High performance processor module GE

IS200VCMIH2B GE power control board

IS200ESELH1AAA I/O excitation redundant module GE

IS200PSCDG1A GE power control board

IS215UCVEM08B High performance processor module GE

IS200ICBDH1ABB High performance processor module GE

DS200ACNAG1A Gas turbine system Mark VI

IS200TBAIH1C High performance processor module GE

IS200DSPXH1DBD Gas turbine system Mark VI

IS200ERGTH1AAA From General Electric in the United States

IS200IGPAG2AED Processor/Controller Mark VI System

IS220PAICH1A Gas turbine system Mark VI

IS420UCSCH2A GE power control board

IS420PUAAH1A I/O excitation redundant module GE

DS200TCDAG1PR5A High performance processor module GE

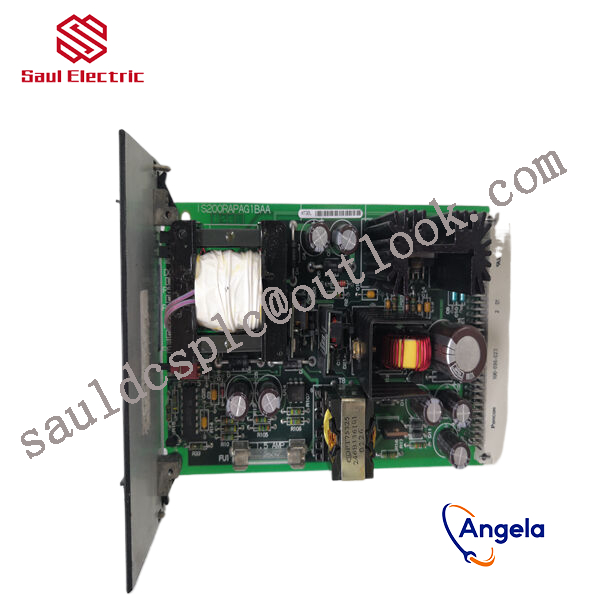

IS200RAPAG1A High performance processor module GE

IS200DAMDG1AAA I/O excitation redundant module GE

IS200EPSMG2ADC GE power control board

IS200HFPAG1A I/O excitation redundant module GE

IS420YDIAS1B I/O excitation redundant module GE

IS200RAPAG1A From General Electric in the United States

IS210AEAAH1B High performance processor module GE

IS210AEAAH1B Gas turbine system Mark VI

DS200SLCCG4A High performance processor module GE

DS200ADMAH1A High performance processor module GE

IS215UCVEM01A High performance processor module GE

IS210MACCH2A High performance processor module GE

IS410JPDHG1A High performance processor module GE

IS215VCMIH2BB From General Electric in the United States

IS220PDIOH1B High performance processor module GE

GDS1168-PFF-PA-NF From General Electric in the United States

IS200IGDMH1AAA Processor/Controller Mark VI System

IS200TVIBH2B Gas turbine system Mark VI

IS220PSCAH1A Gas turbine system Mark VI

IS220PPDAH1A High performance processor module GE

IS420USBH1A I/O excitation redundant module GE

IS410STCIS2A GE power control board

IS200STCIH6AED Processor/Controller Mark VI System

IS200VTURH2BAC Processor/Controller Mark VI System

IS200VRTDH1B Processor/Controller Mark VI System

IS200SRTDH2ACB GE power control board

IS215AEPCH1C Processor/Controller Mark VI System

IS220PAOCH1A Gas turbine system Mark VI

DS200DTBDG1ABB GE power control board

IS420UCSCH1B Gas turbine system Mark VI

DS200PLIBG1ACA High performance processor module GE

IS200SSBAG1A GE power control board

IS200STAOH2AAA GE power control board