Description

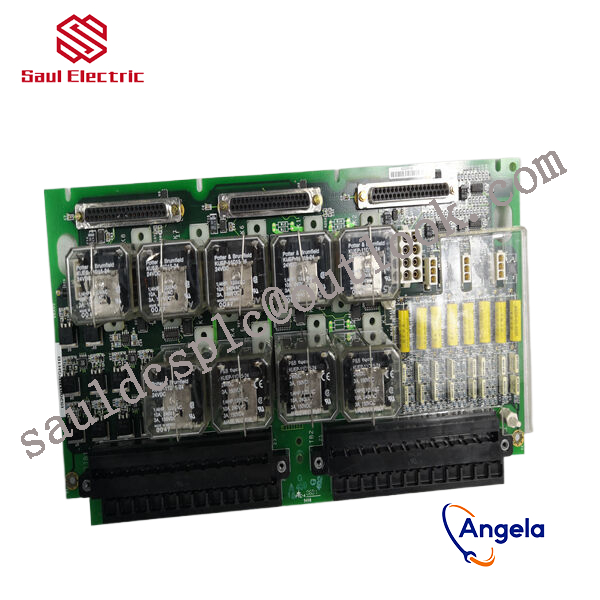

DS200TBQAG1ABB Product Introduction

The specific application scope of the product

will depend on the needs of system integration and industrial application, but generally speaking, this type of embedded controller module can be applied to the following categories:

manufacturing processes, etc.

monitoring and control system.

of the controller module, as well as the specific needs of the customer.

designed to manage gas or steam turbines.

It has a CIMPLICITY graphical interface and an HMI with software suitable for running heavy-duty turbines.

be installed at the bottom of the cabinet. For a small setup that is easy to serve a triple redundant system, up to three components can be installed side by side.

he board can operate within a temperature range of 0 to 65 degrees Celsius without the need for a fan for cooling. NFPA Class 1. This board can be used for two applications.

Double-decker train uses ABB traction transformer for the first timeRapid urbanization has brought about problems such as traffic congestion, air pollution and population expansion, forcing railway operators and infrastructure providers to transport more passengers on already busy rail transit systems. One solution to this outstanding contradiction is to increase the passenger capacity of existing transportation lines.On July 22, 2011, ABB , the world”s leading power and automation technology group, recently announced that Bombardier designed and manufactured the world”s first traction transformer that can be installed on the top of the locomotive for its new generation double-deck EMU train . This train can be used in commuter, regional and intercity rail transit. The use of double-decker trains is a good way to increase passenger capacity. This type of train has the best car seat ratio planning, and the improved acceleration performance of the train also effectively shortens the travel time between stations and expands the coverage of train services.The latest Bombardier double-decker trains have an ABB traction transformer installed on the top. They adopt an extra-wide body and better seat planning. The number of seats per meter of the body ranges from 5 to 5.8, providing more space for passengers. Compared with similar models currently on the market, Bombardier”s new trains can carry 35% more passengers.ABB and Bombardier have a long-standing relationship in the field of traction equipment for regional commuter trains, high-speed trains and railway locomotives. The traction transformer converts the grid voltage from the power grid above the train into the lower voltage required by the train”s traction system, and delivers it to the train”s driving equipment, as well as lighting, heating, ventilation systems, on-board LCD displays, information systems and other electrical system .In order to ensure the continuity of railway transportation and the effectiveness and reliability of the highest level of instant power supply, ABB specially designed traction transformers for OMNEO trains. Compared with the traction transformer on the single-layer SP AC IUM* EMU train provided by Bombardier for the Francilien line in the Paris region of France , the power supply capacity of the new transformer is increased by 25%. To save space, the roof-mounted traction system combines the separate cooling systems for the converter and transformer. This design reduces the number of fans while reducing cost and equipment weight. In addition, in order to save space and facilitate equipment maintenance and control, the transformer will be installed directly on the top channel of the vehicle.Bombardier worked with ABB to complete the design work, and the cabin baffles were installed on the inverter , cooling system and transformer to ensure that these components fit perfectly into the arc-shaped roof and are difficult to see from the outside after installation. In order to solve the problem of the high center of gravity of the double-decker train carriage, the transformer has also been designed accordingly to evenly distribute the weight of the equipment.Swiss ABB will build the largest solar power plant in Northern EuropeSwiss power and automation technology group ABB announced on August 11 that it has built the largest solar power station in Northern Europe at its low-voltage AC drive plant in Finland . The total investment in the entire solar power station project is approximately 500,000 euros, part of which comes from the Finnish government. renewable energy investment fund.ABB Finland”s low-voltage AC transmission plant is located in Helsinki. This solar power station is located on the roof of the factory and has a power of 181 kilowatts. The solar power generated is mainly used to charge the factory”s forklift truck batteries and reduce the peak load of the factory”s electricity consumption.Antti Suontausta, Senior Vice President of ABB”s low-voltage AC drives business, said: “This solar power generation system fully demonstrates the benefits of distributed power generation near power consumption areas. Solar power generation can bring high added value to users, especially for commercial and industrial applications . For buildings, solar power generation can reduce the building’s peak power load.”Finland”s sunshine is not very abundant, but this solar power station can take full advantage of the region”s long sunshine hours in summer. It is expected to generate 160,000 kilowatt hours of electricity per year, which is equivalent to the annual use of 30 local households that do not use electric heating equipment. power. This solar power will be directly integrated into the factory power grid to charge the forklift trucks in the factory, and the excess power can also be used by other equipment.The solar power station uses ABB”s latest string inverters and central inverters, which are designed and produced by ABB”s transmission plant in Helsinki. This is their first application in Finland. ABB solar inverters are mainly used to convert DC power produced by solar panels into high-quality AC power and integrate it into the power grid.

IS200TTURH1B Processor/Controller Mark VI System

IS200ACLEH1ABA From General Electric in the United States

IS220UCSH1A Processor/Controller Mark VI System

DS200DSPCH1ADA Processor/Controller Mark VI System

IS215VCMIH1B From General Electric in the United States

IS210BPPBH2CAA GE power control board

DS200PTBAG1BAA Processor/Controller Mark VI System

IS200TREGH1B From General Electric in the United States

IS200EGDMH1A GE power control board

IS200VAOCH1B Processor/Controller Mark VI System

IS215UCVEH2A GE power control board

IS410JPDSG1A Processor/Controller Mark VI System

IS200EISBH1A Processor/Controller Mark VI System

IS200EDEXG1A I/O excitation redundant module GE

IS200STCIH4A I/O excitation redundant module GE

DS200SDCIG2A Processor/Controller Mark VI System

IS200WNPSH1ABA From General Electric in the United States

IS210DTRTH1A From General Electric in the United States

IS200TTURH1CFD High performance processor module GE

IS215UCVEM06A I/O excitation redundant module GE

DS200QTBAG1ADC From General Electric in the United States

IS200IGDMH1AAA High performance processor module GE

IS420PPDAH1B Processor/Controller Mark VI System

IS215PMVPH1A High performance processor module GE

DS200TCEBG1A High performance processor module GE

DS200DACAG1ACD High performance processor module GE

DS200KLDBG1A Gas turbine system Mark VI

IS200ERRBG1A Gas turbine system Mark VI

DS200GDPAG1A Gas turbine system Mark VI

IS420ESWAH4A From General Electric in the United States

IS210MVRAH2A I/O excitation redundant module GE

IS200TBTCH1B Gas turbine system Mark VI

IS210DRTH1AA Processor/Controller Mark VI System

IS200STAIH2A I/O excitation redundant module GE

IS2020RKPSG2A Gas turbine system Mark VI

IS215PMVPH1A Gas turbine system Mark VI

IS200ESYSH1AAA Gas turbine system Mark VI

DS200PTCTG2BAA From General Electric in the United States

IS200TSVOH1BCC GE power control board

DS200SDCCG4AGD High performance processor module GE

IS200TVIBH2BBB From General Electric in the United States

IS200ECTBG2A From General Electric in the United States

IS220PAOCH1A Processor/Controller Mark VI System

IS215UCVEM09A GE power control board

IS200AVGBG1AAA From General Electric in the United States

IS215WETAH1BB From General Electric in the United States

IS200BPIIH1AAA Gas turbine system Mark VI

IS200DAMDG1A Processor/Controller Mark VI System

IS420UCPAH1A I/O excitation redundant module GE

DS200TCDAG1BDB I/O excitation redundant module GE

DS200PCCAG7ACB I/O excitation redundant module GE

IS220PSCAH1B Gas turbine system Mark VI

IS230PTURHIA High performance processor module GE

DS200TCQAG1B From General Electric in the United States

IS200TBTCH1B From General Electric in the United States

IS220YDOAS1AJ I/O excitation redundant module GE

IS200ISBDG1A From General Electric in the United States

IS200SSCAH2A Gas turbine system Mark VI

IS200JPDMG1A GE power control board

IS210MACCH1AKH GE power control board

IS215UCVEH2AF High performance processor module GE

IS200ERSCG1A High performance processor module GE

DS200LDCFBG1BNC High performance processor module GE

DS200PLIBG2ACA I/O excitation redundant module GE

IS420ESWBH1A Processor/Controller Mark VI System

IS420YVIBS1B High performance processor module GE

IS200DTCIH1A GE power control board

IS200EPBPG1ACD From General Electric in the United States

IS220PTURH1B GE power control board

IS200RAPAG1BBA From General Electric in the United States

DS200TCRAG1ACC Gas turbine system Mark VI

DS200VPBLG1ADD GE power control board

DS200DSPCH1ADA I/O excitation redundant module GE

DS215TCQAG1BZZ01A Processor/Controller Mark VI System

IS200EISBH1A From General Electric in the United States

IS200DSPXH2B Processor/Controller Mark VI System

DS200TCPDG1BEC Gas turbine system Mark VI

IS210BAPAH1A I/O excitation redundant module GE

IS230STTCH2A High performance processor module GE

IS215UCVDH2AM Processor/Controller Mark VI System

IS2020RKPSG2A From General Electric in the United States

IS220PTCCH1A I/O excitation redundant module GE