Description

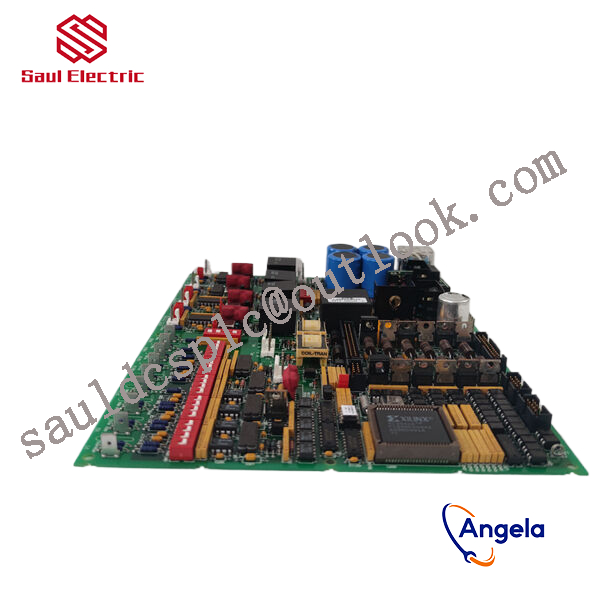

DS200DCFBG1BLC Product Introduction

The specific application scope of the product

will depend on the needs of system integration and industrial application, but generally speaking, this type of embedded controller module can be applied to the following categories:

manufacturing processes, etc.

monitoring and control system.

of the controller module, as well as the specific needs of the customer.

designed to manage gas or steam turbines.

It has a CIMPLICITY graphical interface and an HMI with software suitable for running heavy-duty turbines.

be installed at the bottom of the cabinet. For a small setup that is easy to serve a triple redundant system, up to three components can be installed side by side.

he board can operate within a temperature range of 0 to 65 degrees Celsius without the need for a fan for cooling. NFPA Class 1. This board can be used for two applications.

(2) Data collection and traceability issues. Data collection issues often occur, and many assembly lines lack “end-to-end traceability.” In other words, there are often no unique identifiers associated with the parts and processing steps being produced. One workaround is to use a timestamp instead of an identifier. Another situation involves an incomplete data set. In this case, omit incomplete information parts or instances from the forecast and analysis, or use some estimation method (after consulting with manufacturing experts).(3) A large number of features. Different from the data sets in traditional data mining, the features observed in manufacturing analysis may be thousands. Care must therefore be taken to avoid that machine learning algorithms can only work with reduced datasets (i.e. datasets with a small number of features).(4) Multicollinearity, when products pass through the assembly line, different measurement methods are taken at different stations in the production process. Some of these measurements can be highly correlated, however many machine learning and data mining algorithm properties are independent of each other, and multicollinearity issues should be carefully studied for the proposed analysis method.(5) Classification imbalance problem, where there is a huge imbalance between good and bad parts (or scrap, that is, parts that do not pass quality control testing). Ratios may range from 9:1 to even lower than 99,000,000:1. It is difficult to distinguish good parts from scrap using standard classification techniques, so several methods for handling class imbalance have been proposed and applied to manufacturing analysis [8].(6) Non-stationary data, the underlying manufacturing process may change due to various factors such as changes in suppliers or operators and calibration deviations in machines. There is therefore a need to apply more robust methods to the non-stationary nature of the data. (7) Models can be difficult to interpret, and production and quality control engineers need to understand the analytical solutions that inform process or design changes. Otherwise the generated recommendations and decisions may be ignored.

DS200TCDAG1BDB High performance processor module GE

IS200ISBBG2AAB High performance processor module GE

DS215KLDBG1AZZ03A I/O excitation redundant module GE

IS220PSVOH1A High performance processor module GE

IS200EPSMG1A Gas turbine system Mark VI

DS200SHCAG1BAA I/O excitation redundant module GE

IS200PSCDG1A From General Electric in the United States

IS215UCVDH2AK Gas turbine system Mark VI

IS200JPDMG1ADC GE power control board

DS200TCEAG1BSF Gas turbine system Mark VI

IS200TRLYH1B GE power control board

IS200EACFG2A GE power control board

IS200VSVOH1BDC Gas turbine system Mark VI

IS200TDBSH2AAA I/O excitation redundant module GE

IS210AEAAH1BBA I/O excitation redundant module GE

IS220PRTDH1A I/O excitation redundant module GE

DS200DDTBG2A GE power control board

IS200CPFPG1A Gas turbine system Mark VI

IS220PHRAH1B GE power control board

DS200PTBAG1ADC GE power control board

DS200TCDAG1B Processor/Controller Mark VI System

IS210SCSAS1A From General Electric in the United States

IS210AEAAH1B I/O excitation redundant module GE

IS220PSFDH1AG GE power control board

IS215GFOIH1A From General Electric in the United States

IS200VRTDH1BAB I/O excitation redundant module GE

IS200TRTDH1B High performance processor module GE

IS200EMIOH1AFB Gas turbine system Mark VI

IS200ERSCG2A From General Electric in the United States

IS200JPDLG1A I/O excitation redundant module GE

IS420ESWBH2A I/O excitation redundant module GE

IS23OSTTCH2A Gas turbine system Mark VI

IS200SCTLG1A Gas turbine system Mark VI

IS200TRPGH3B GE power control board

IS200DAMCG1 High performance processor module GE

IS200ECTBG1A Gas turbine system Mark VI

IS200SCTLG1ABA GE power control board

IS200JPDFG1A From General Electric in the United States

IS200ECTBG2A Processor/Controller Mark VI System

8201-HI-IS From General Electric in the United States

IS210MACCH1A High performance processor module GE

IS230TCISH6C I/O excitation redundant module GE

IS220PTCCH1A From General Electric in the United States

IS200DSPXH1DB Gas turbine system Mark VI

IS220PAICH2B High performance processor module GE

IS200TBACIH1B From General Electric in the United States

DS200TBQCG1AAA GE power control board

DS200IMCPG1CEB Gas turbine system Mark VI