Description

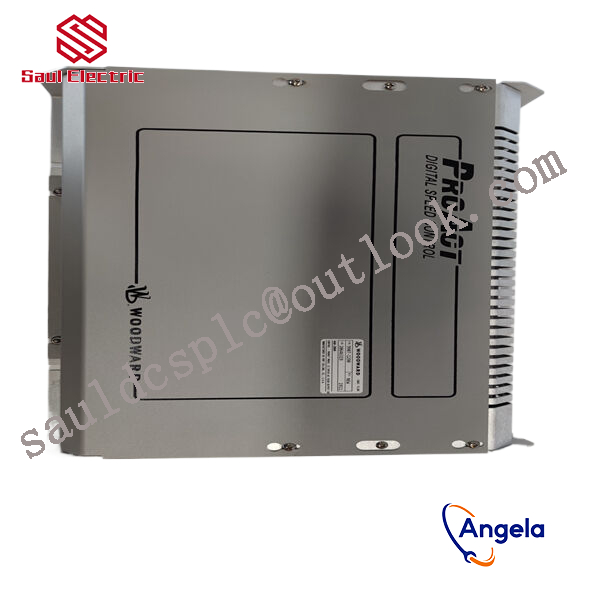

8236-144D WOODWARD Speed Sensor Full Series

8236-144D Product Introduction

Non differential regulation is mainly used for constant speed control and is suitable for single machine operation or multiple prime movers working together in an isolated power grid. Differential regulation provides more control flexibility.

further enhancing its performance and application range.

rich additional functions, and high-precision output signals. Whether it is in the fields of generator sets, compressors, pump stations, or ships and locomotives, it can effectively ensure the stable operation of equipment within the set range.

power measurement level 1, editable screen, multi interface toolkit connection, etc. All details can be found in Woodward easyYgen manual 37582A

The rated operating temperature range of this model is -20 to 70 ° C; the rated temperature range of the LT model is -40 to 70 ° C, suitable for outdoor use.

8236-144D is equipped with a monitor (not available on the 3100 model) and is designed for front panel installation.

The built-in HMI has a color LCD and soft keys (now with dedicated buttons) for direct control of the 8236-144D device. Multi level password protection can prevent unauthorized changes.

The generator set has four operating modes and the option to configure a manual circuit breaker control device.

How to use 8236-144D?

What is 8236-144D used for?

8236-144D Customs Code

However, our country started late in high-end manufacturing fields such as robotics, artificial intelligence, and cloud computing. Most of them started after 2000. The development time was not long, and it was not placed in the main position for a long time, resulting in a very insufficient talent reserve. . The “Manufacturing Talent Development Planning Guide” points out that by 2025, the talent gap in the fields related to high-end CNC machine tools and robots will reach 4.5 million people. It also points out that the talent shortage in the top ten key areas of the manufacturing industry will exceed 19 million in 2020. This number is nearly 30 million per year. From the most basic operations and programming to the complex debugging and maintenance of the entire robot system , we have scarcity problems in all aspects of research talents , engineering talents , and highly skilled talents . This will undoubtedly greatly hinder the development of the entire robot market. In the future A small number of talents will flock to leading companies with high profits, while most small and medium-sized enterprises will not even be able to get fresh graduates, thus losing the motivation to progress. The problem of talent shortage will not be alleviated in a short time In just a few decades after the reform and opening up, my country”s manufacturing industry has achieved tremendous development and has become a well-deserved world factory, supplying the world with the power of one country. Behind this unprecedented prosperity, we have been relying on three dividends, in addition to In addition to the dividends of globalization and demographic dividends, there is actually a talent dividend that is often overlooked. In other words, we do not lack talents due to past development.

ug-8 WOODWARD generator set speed control board

8522-447 Generator Parts Speed Controller 2301A Speed

5463-397 WOODWARD Speed Sensor Full Series

5463-154 From Woodward, USA

8915-004 Generator Parts Speed Controller 2301A Speed

5463-034 WOODWARD generator set speed control board

5501-381 WOODWARD generator set speed control board

1886-313 From Woodward, USA

8237-2601 Generator Parts Speed Controller 2301A Speed

9905-760 WOODWARD Speed Sensor Full Series

5464-223 Controller debugger generator WOODWARD

9905-876 WOODWARD generator set speed control board

5460-841 WOODWARD Speed Sensor Full Series

9907-1198 WOODWARD 2301A Speed Control Controller

9905-707 Controller debugger generator WOODWARD

5463-881 Controller debugger generator WOODWARD

8230-898 Generator Parts Speed Controller 2301A Speed

9905-096 WOODWARD generator set speed control board

5460-837 Controller debugger generator WOODWARD

5461-772 WOODWARD Speed Sensor Full Series

5463-583 WOODWARD 2301A Speed Control Controller

5439-273 From Woodward, USA

1790-789 Controller debugger generator WOODWARD

B8571-163 WOODWARD generator set speed control board

5439-273 WOODWARD generator set speed control board

5501-467 Controller debugger generator WOODWARD

5466-1035 WOODWARD Speed Sensor Full Series

5484-875 WOODWARD 2301A Speed Control Controller

8226-043 WOODWARD 2301A Speed Control Controller

8440-1715 SPM-D11 From Woodward, USA

9907-1198 WOODWARD generator set speed control board

5417-175 WOODWARD generator set speed control board

5463-796 WOODWARD Speed Sensor Full Series

5462-750 WOODWARD generator set speed control board