Description

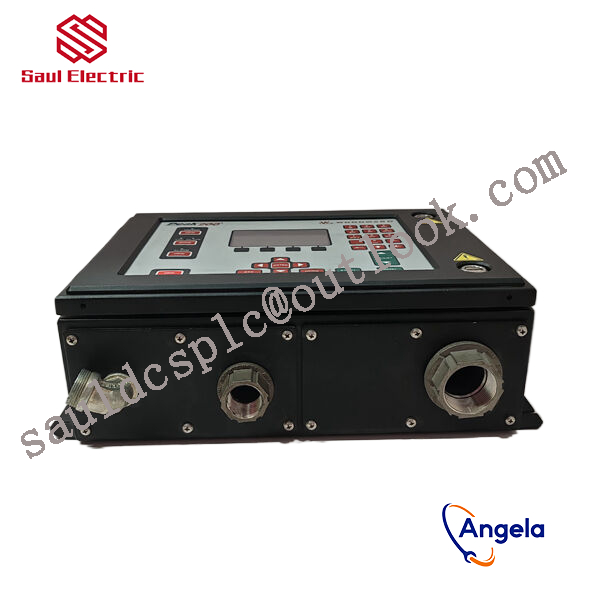

5441-693 WOODWARD Speed Sensor Full Series

5441-693 Product Introduction

Non differential regulation is mainly used for constant speed control and is suitable for single machine operation or multiple prime movers working together in an isolated power grid. Differential regulation provides more control flexibility.

further enhancing its performance and application range.

rich additional functions, and high-precision output signals. Whether it is in the fields of generator sets, compressors, pump stations, or ships and locomotives, it can effectively ensure the stable operation of equipment within the set range.

power measurement level 1, editable screen, multi interface toolkit connection, etc. All details can be found in Woodward easyYgen manual 37582A

The rated operating temperature range of this model is -20 to 70 ° C; the rated temperature range of the LT model is -40 to 70 ° C, suitable for outdoor use.

5441-693 is equipped with a monitor (not available on the 3100 model) and is designed for front panel installation.

The built-in HMI has a color LCD and soft keys (now with dedicated buttons) for direct control of the 5441-693 device. Multi level password protection can prevent unauthorized changes.

The generator set has four operating modes and the option to configure a manual circuit breaker control device.

How to use 5441-693?

What is 5441-693 used for?

5441-693 Customs Code

Comment: With product trends such as smartphones and smart hardware, demand in the semiconductor electronics industry has grown rapidly and has become one of the main markets for robots. It is expected to soon exceed the demand in the automotive industry and become the dominant market for industrial robots. Xinsong”s acquisition of FA Company, a subsidiary of Xinsheng, provides a bridge for the company to enter the semiconductor field and take a share of the largest application market for robots in the future.Honda halts ASIMO humanoid robot development projectThe research and development process of robots requires a lot of investment in money and manpower, especially in products with special functions. In July this year, Japanese car manufacturer Honda stated that it would stop developing the humanoid robot ASIMO. As the world”s first humanoid robot, the product has completed its seventh iteration and is already capable of running, jumping, climbing stairs, opening drinks, and kicking. It has many abilities including football and even dancing, being able to hear and understand three people speaking at the same time, and interpret gestures and respond to various commands.Although the research and development of the ASIMO project has stopped, the project retains a number of technologies that can be used in mobile robots and self-driving cars, because many technologies in ASIMO are still world-leading. ASIMO has gone through a long period of research and development upgrades, but it is still far from commercial application, and the price is difficult for users to accept. Honda finally chose to give up.Comments: Technology innovation and research and development to real commercial applications need to cross many gaps. Currently, humanoid robots are still a difficult problem to break through in commercial applications. In addition to pleasing the audience, humanoid robots are difficult to form real commercial value. At this stage, the market needs products that meet the application needs of various industries, such as four- and six-axis industrial robots, collaborative robots, etc., so the robot R&D department needs to make appropriate choices.FANUC Robotics” new factory starts construction in GuangzhouOn March 28, Fanuc, a leading company in the global robotics industry, held a groundbreaking and opening ceremony for its new factory in Guangzhou Science City. In order to meet the needs of the market, Shanghai Fanuc Co., Ltd. cooperated with the Guangzhou Development Zone to build a new factory in the Science City and established a subsidiary, Guangzhou Fanuc Robot Co., Ltd. The new company has a registered capital of 150 million yuan and the company occupies an area of The area is close to 40,000 square meters.The construction of the new factory means that Fanuc will form two major formations in China: Shanghai Fanuc and Guangzhou Fanuc. Guangzhou will integrate Fanuc”s resources in the south to form a South China base that integrates robot sales, display and training. . As a core area for intelligent equipment, Guangzhou is committed to promoting the development of the intelligent manufacturing industry. This cooperation will further promote the intelligent transformation and upgrading of the Pearl River Delta manufacturing industry.Comment: China has become the world”s largest industrial robot market for five consecutive years. As a major manufacturing country in the world, it is promoting the transformation of China”s manufacturing into China”s intelligent manufacturing, and at the same time, it has given birth to a huge robot market. Against this background, domestic and foreign robot manufacturers are making plans one after another, and Fanuc”s investment in building new factories is also fully optimistic about the Chinese robot market. In addition, the new factory in Guangzhou will make up for Shanghai Fanuc”s shortcomings in the south and further reduce the transportation costs of products.China Southern Power Grid”s first self-developed substation inspection robot comes on duty

9907-055 From Woodward, USA

5417-027 Controller debugger generator WOODWARD

UG-10D WOODWARD generator set speed control board

5463-428 From Woodward, USA

5417-1105 WOODWARD generator set speed control board

9905-096 From Woodward, USA

8440-1666 WOODWARD 2301A Speed Control Controller

5464-355 Generator Parts Speed Controller 2301A Speed

5416-337 From Woodward, USA

8440-1947 Controller debugger generator WOODWARD

5416-338 Generator Parts Speed Controller 2301A Speed

5462-527 WOODWARD generator set speed control board

5466-352 Controller debugger generator WOODWARD

DPG-2223-002 From Woodward, USA

5441-661 From Woodward, USA

5463-396 Controller debugger generator WOODWARD

9905-968 WOODWARD 2301A Speed Control Controller

8200-226 WOODWARD 2301A Speed Control Controller

5462-762 WOODWARD 2301A Speed Control Controller

5501-428 WOODWARD generator set speed control board

9905-876 Controller debugger generator WOODWARD

5462-443 WOODWARD 2301A Speed Control Controller

5503-173 WOODWARD Speed Sensor Full Series

5463-887 WOODWARD Speed Sensor Full Series

8516-038 Controller debugger generator WOODWARD

5501-432 From Woodward, USA

8200-1204 WOODWARD Speed Sensor Full Series

8440-2145 Controller debugger generator WOODWARD

8440-1955 WOODWARD generator set speed control board

5462-757 Controller debugger generator WOODWARD

9905-969 WOODWARD generator set speed control board

8440-1666 From Woodward, USA

9907-298 WOODWARD 2301A Speed Control Controller

5462-757 Generator Parts Speed Controller 2301A Speed

5464-646 WOODWARD 2301A Speed Control Controller